The Future of Asset Management Software for Facilities: AI and IoT

Explore how AI and IoT are shaping the future of asset management software for facilities and why it matters for your business.

Managing facility assets is challenging - manual tracking, unexpected downtime, and rising costs make the job harder every day. Traditional tools can’t keep up.

Enter AI and IoT. These technologies are transforming asset management software for facilities, enabling predictive maintenance, real-time monitoring, and smarter decisions.

In this article, we’ll explore how AI and IoT are shaping the future, and what it means for your facility.

The Current State of Asset Management Software for Facilities

If you manage a facility, you already know how challenging it is to stay on top of everything: equipment, systems, maintenance schedules, and costs. Spreadsheets and outdated tools might have worked before, but today they create more problems than they solve:

- Important asset data is scattered or outdated

- Maintenance is reactive instead of proactive, leading to costly downtime

- Compliance and audits become time-consuming and stressful

What Does Asset Management Software for Facilities Do?

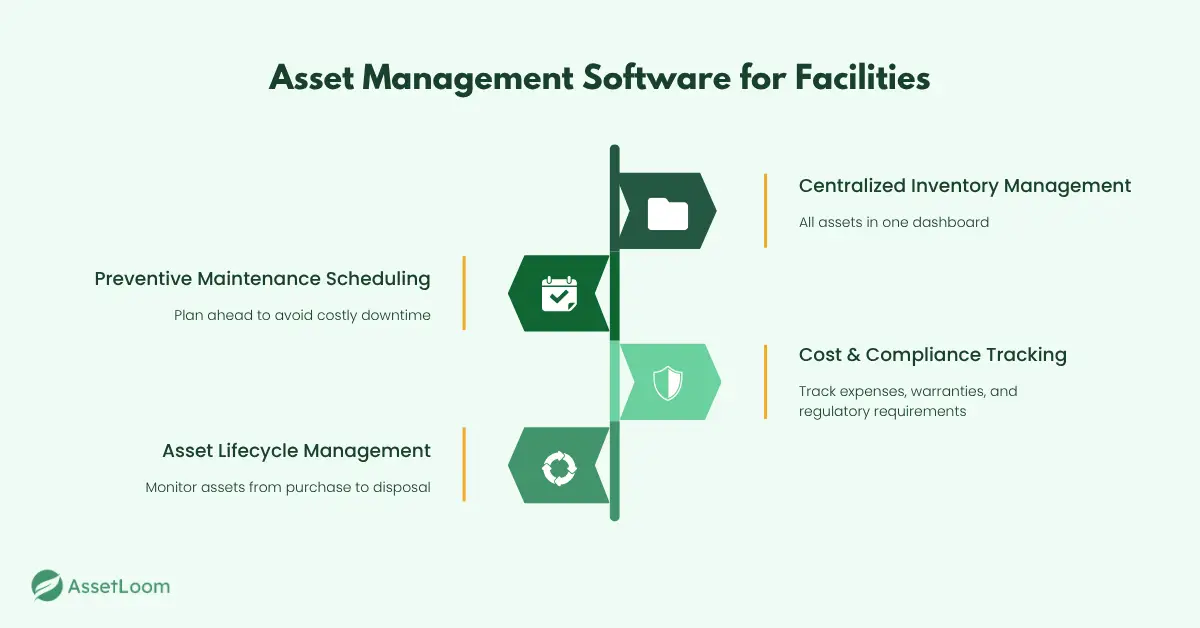

In simple terms, asset management software for facilities is designed to make your job easier. It provides centralized asset inventory management so you can see all your assets in one place and manage them through their entire lifecycle, from purchase to disposal. This includes HVAC systems, electrical equipment, machinery, vehicles, and more.

With the right software, you can:

- Maintain a complete, accurate asset inventory in a single dashboard

- Schedule preventive maintenance before breakdowns happen

- Track costs, warranties, and compliance records without juggling multiple tools

How Is It Different from Software for IT Asset Management?

Many businesses already use software for IT asset management to manage laptops, servers, and licenses. Facility asset management works on the same principle but adds a layer of complexity. Physical assets wear out, require regular servicing, and can cause major disruptions if they fail. This makes automation and real-time data critical for success.

Traditional tools do not offer this level of control. This is why modern platforms powered by AI and IoT are becoming essential to help facilities shift from reactive firefighting to proactive planning.

The Role of AI in Asset Management Software for Facilities

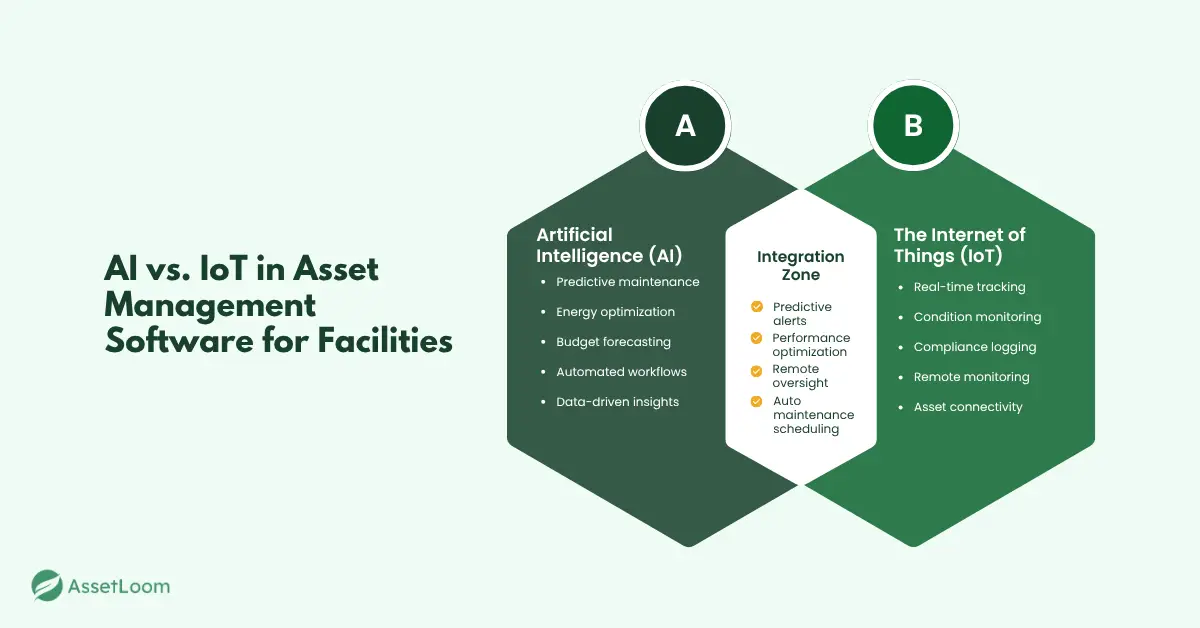

Artificial Intelligence is transforming how facilities manage maintenance, budgets, and daily operations. Instead of reacting to problems after they happen, AI gives facility managers tools to predict and prevent them. Here are practical ways to apply AI in real-world scenarios:

1. Predictive Maintenance

AI analyzes historical data and real-time sensor inputs to predict when an asset is likely to fail. This allows teams to schedule service before breakdowns occur, reducing downtime and emergency repair costs.

Practical tip: Start with your most critical assets, such as HVAC systems or production machinery. Connect their usage data to your asset management software and set automated alerts for early warnings.

2. Energy Optimization and Cost Reduction

AI detects patterns in energy usage across your facility. It can identify when systems are running unnecessarily, such as HVAC units operating outside business hours, and suggest adjustments to reduce waste.

Practical tip: Use AI-generated energy reports to identify the top three areas where you can cut consumption. Even small changes in scheduling or settings can lead to significant savings.

3. Smarter Budget Forecasting

Unexpected repairs can derail budgets. AI provides accurate forecasts by analyzing historical costs, asset age, and upcoming maintenance needs. This helps in building realistic budgets that management can approve with confidence.

Practical tip: Combine AI-driven cost predictions with your financial planning process. Present data-backed insights during budget discussions to secure the resources you need.

4. Automating Low-Value Tasks

AI can automatically create work orders when conditions are met, such as when sensor data indicates unusual activity or a maintenance threshold is reached. This reduces manual scheduling errors and saves time.

Practical tip: Set up rules in your asset management software so that when vibration, temperature, or other conditions cross a defined limit, a work order is generated automatically.

AI turns raw data into actionable insights, helping facilities cut costs, extend asset life, and operate more efficiently. When combined with IoT, these capabilities become even more powerful.

The Power of IoT in Asset Management Software for Facilities

The Internet of Things (IoT) is a game-changer for facility management because it connects physical assets to digital systems through sensors and smart devices. This real-time data allows teams to monitor, control, and optimize assets more effectively than ever before. Here are practical ways IoT can make a difference in your facility:

1. Real-Time Asset Tracking

Knowing the exact location and status of every asset saves hours of manual work and prevents costly misplacements. IoT-enabled tags or sensors provide continuous updates on asset movement and usage.

Practical tip: Start by tagging high-value or frequently moved assets such as critical machinery, HVAC units, or tools. This ensures nothing goes missing and improves accountability.

2. Condition Monitoring for Critical Equipment

IoT sensors can track temperature, vibration, and energy usage. If an abnormal reading occurs, the system can trigger an alert or even create a maintenance work order automatically.

Practical tip: Deploy sensors on assets prone to breakdowns. For example, install vibration sensors on motors or compressors to detect early signs of wear before failure occurs.

3. Compliance Made Easier

For regulated industries like healthcare or manufacturing, IoT can log environmental conditions such as temperature or humidity without manual checks. These automated records simplify compliance reporting and reduce human error.

Practical tip: Use IoT for automated audit trails. Set up dashboards that generate compliance reports with a single click instead of manual data collection.

4. Remote Management Across Multiple Sites

Facilities with multiple locations often struggle with visibility. IoT bridges this gap by giving managers a single view of all connected assets.

Practical tip: Centralize IoT data within your asset management software. This allows your team to track, manage, and maintain equipment remotely without constant on-site visits.

When IoT connects to your asset tracking software, you gain real-time insights into location, condition, and performance, eliminating guesswork.

IoT delivers visibility and control, but its real potential emerges when combined with AI. Together, they transform raw data into predictive insights and automated actions, setting the stage for the future of asset management.

AI + IoT: A Game-Changer for Facilities

When AI and IoT work together, they create a system that does more than monitor assets. It predicts issues, automates responses, and optimizes performance in real time. This combination shifts facility management from a reactive process to a proactive strategy.

Practical Applications:

- Smart HVAC Monitoring: IoT sensors gather data on temperature and energy usage. AI analyzes this information and adjusts operations to reduce energy waste while maintaining comfort levels.

- Early Failure Detection: IoT sensors monitor critical metrics such as vibration and temperature. AI identifies abnormal patterns and triggers alerts or creates maintenance work orders before a breakdown occurs.

- Remote Oversight: IoT provides real-time data from multiple locations. AI then prioritizes the most urgent issues, enabling faster decision-making and reducing unnecessary site visits.

This integrated approach delivers tangible benefits: lower maintenance costs, improved asset reliability, and greater energy efficiency.

Future Predictions for Asset Management Software in Facilities

The next phase of asset management is being shaped by technologies that improve accuracy, efficiency, and sustainability. Key developments to watch include:

- AI-Powered Digital Twins: These virtual models of assets or entire facilities use real-time IoT data to simulate performance and predict future scenarios. This helps managers plan upgrades or repairs with precision.

- Predictive Procurement: AI will forecast when assets are nearing the end of their lifecycle and recommend replacements before failure, minimizing emergency costs.

- Sustainability and Energy Optimization: Regulatory requirements and energy costs will drive the adoption of AI-powered analytics for reducing waste and monitoring compliance.

- Cloud-Based Platforms as the Standard: Cloud infrastructure will be essential for integrating AI, IoT, and mobile systems, providing real-time collaboration across distributed teams.

Conclusion

Facility management is changing fast. AI and IoT are no longer buzzwords; they’re practical tools that help predict issues, cut costs, and keep operations running smoothly.

Those who embrace these technologies will move from constant firefighting to smarter, proactive management. The shift has already started. The question is: will you be ready for what’s next?

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.