Fixing Disconnected Inventory Systems Between Departments

Disconnected inventory systems refer to separate tools or processes used by different departments to track inventory without shared access, visibility, or coordination.

One department orders new laptops while another has extras collecting dust. Finance says everything is accounted for, but HR is missing onboarding kits. Sound familiar?

This isn’t just poor tracking. It’s a disconnect between departments. Each team manages inventory in its own way. IT uses a ticketing system. Finance logs assets in an ERP. HR updates spreadsheets. The tools might work fine, just not together.

When systems aren't aligned, the result is duplicate purchases, delays, inaccurate data, and frustrated teams.

In this blog, you’ll learn:

- What disconnected inventory systems between departments actually mean

- How they affect your business

- Why they happen

- And how to fix them with clear, cross-team solutions

What Are Disconnected Inventory Systems Between Departments?

Disconnected inventory systems refer to separate tools or processes used by different departments to track inventory without shared access, visibility, or coordination.

In other words, each team tracks what they need but in their own way, in their own system, with no connection to others.

This isn't about bad tools. It's about using tools in isolation. IT might use a ticketing platform to manage devices. Finance logs purchases in an ERP. HR tracks onboarding kits in spreadsheets. They’re all doing their job, just not in sync.

The result? Assets are tracked in multiple places, but no one has a complete picture. Updates get lost, numbers don’t match, and nobody knows which version is right.

It’s not that your teams don’t care about inventory. It’s that their systems were never designed to work together.

For example, IT might use a ticketing tool to manage laptops and software. Finance may record purchases in an ERP system. HR could be tracking onboarding kits in spreadsheets. Individually, these systems may function well. But because they are not connected or aligned, the organization lacks accurate, real-time visibility across the board.

The Real Cost of Cross-Department Inventory Disconnect

When departments don’t share inventory systems, the consequences ripple far beyond a few misplaced assets. For the business as a whole, disconnected systems lead to:

- Wasted spending on duplicate or unnecessary purchases

- Inaccurate financial reporting and poor forecasting

- Slower operations and delayed decision-making

- Lower accountability, especially when things go missing

- Decreased team productivity due to manual coordination

What seems like a tech issue is really a business drain on time, budget, and trust.

Here’s how it plays out across key departments:

IT: Limited visibility and inefficient support

- Once equipment is handed off to an employee, IT often loses track of it.

- Troubleshooting or replacing assets becomes slower and more manual.

- Without unified records, it’s difficult to know what’s in use, what’s idle, or what’s missing.

Finance: Budget confusion and reporting risks

- Disconnected records lead to inconsistent financial data.

- Finance may not know if a purchase was already made, leading to duplicate orders.

- Accurate depreciation, tax reporting, and audits become difficult without a trusted inventory source.

HR: Delayed onboarding and offboarding

- New hires may face delays getting laptops, monitors, or access credentials.

- Offboarding may skip crucial steps, like recovering equipment or deactivating software licenses.

- Without visibility into what each employee is using, HR relies on guesswork.

Operations: Unnecessary purchases and poor planning

- Teams may reorder items that already exist in another department's storage.

- Without a shared system, inventory levels are misjudged, leading to overstock or shortages.

- Procurement lacks the data needed to forecast demand accurately.

Disconnected systems don’t just slow things down; they create blind spots that affect the entire business.

Why Departments Fall Out of Sync

If every team is doing its part, why does everything still feel disconnected? It usually comes down to this: each department manages inventory based on its own needs, using its own systems, without a shared process or central oversight. Over time, that creates silos.

Here are the most common reasons it happens:

- Different Systems: Each department uses tools that suit their workflow ERPs, spreadsheets, ticketing platforms, procurement tools but those systems rarely talk to each other.

- No Integration: Even if the tools are capable, they’re not connected. Data stays trapped in individual systems, and updates don’t sync across teams.

- Manual Handoffs: Asset information is passed between teams via emails, forms, or verbal updates. That’s when things get lost or delayed.

- No Shared Standards: Each team may track inventory differently. One logs by serial number, another by item type. Naming conventions, formats, and even definitions of “in stock” vary.

- Lack of Ownership: Often, no one owns it inventory management across the entire company. Each department assumes another is handling it and the gaps show.

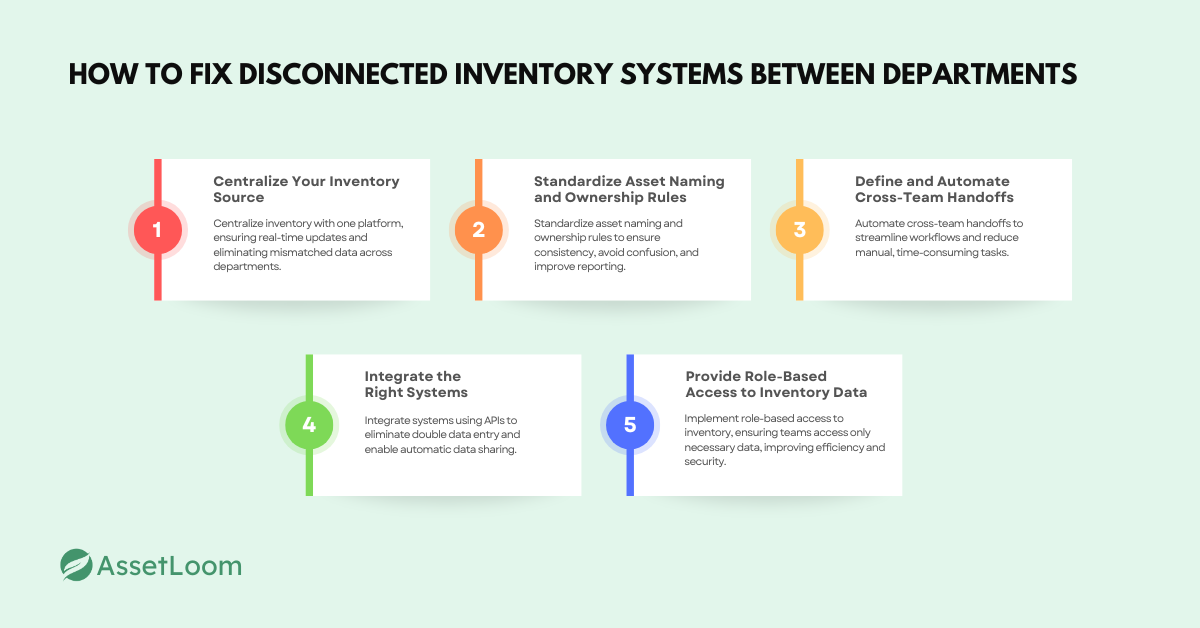

How to Fix Disconnected Inventory Systems Between Departments

Disconnected inventory systems between departments don’t fix themselves. Solving the problem means creating a shared structure not just for how inventory is tracked, but for how teams communicate, take ownership, and use systems together.

Here’s a breakdown of practical, real-world strategies that can help unify your inventory operations across departments:

1. Centralize Your Inventory Source

Each department uses its own system like spreadsheets, ERPs, ticketing platforms which leads to mismatched data and missed updates. Use a centralized inventory platform that acts as a single source of truth, where all departments can log, update, and access asset information in real time.

What this looks like:

- Finance logs purchases, IT records deployments, and HR assigns onboarding kits; all in the same system.

- No more version confusion or outdated spreadsheets.

Example: A mid-sized IT services company switched from three separate systems (ERP for Finance, Trello for IT, and Excel for HR) to a unified asset management platform like AssetLoom. The result? A 40% reduction in duplicate purchases and smoother onboarding processes.

2. Standardize Asset Naming and Ownership Rules

Different teams use inconsistent naming conventions or don’t track ownership clearly, which leads to confusion and reporting errors. Define and enforce consistent rules for asset naming, categorization, and lifecycle tracking.

Best practices:

- Use naming templates (e.g., "LTP-MKT-001" for a laptop in the marketing department).

- Define who is responsible for updating status (e.g., IT marks deployment, HR confirms assignment).

- Create a shared glossary of asset terms so everyone uses the same language.

Why it matters: Consistency avoids miscommunication and ensures clean data across departments; especially when running reports or passing data to external auditors.

3. Define and Automate Cross-Team Handoffs

Manual handoffs like emailing IT to prep laptops or reminding HR to update records are unreliable and time-consuming. Design clear workflows for key processes, and use automation to trigger actions between teams.

Examples:

- When Finance approves a laptop purchase, the system notifies IT to assign the device and logs it in inventory automatically.

- HR starts an onboarding checklist that auto-assigns asset delivery to IT and confirmation to the hiring manager.

Fewer steps fall through the cracks, and you reduce the dependency on memory, follow-ups, or emails.

4. Integrate the Right Systems

Even if teams have good tools, they don’t always connect. This leads to double data entry and delays. Use APIs, native integrations, or middleware to connect your systems so they can share data automatically.

What you might connect:

- ERP (Finance) ↔ Asset Management (IT)

- Procurement Tool ↔ Inventory

- HR Platform ↔ Onboarding Asset List

- Ticketing System ↔ Asset Records

5. Provide Role-Based Access to Inventory Data

Either everyone has access to everything (which is messy and risky), or only one team can see inventory (which causes bottlenecks). Use a system that supports role-based access control (RBAC) so each team can access what they need — no more, no less.

Benefits:

- IT can manage asset status and maintenance.

- Finance can view asset value and depreciation.

- HR can track assigned equipment per employee.

- Leadership gets full visibility without needing to micromanage.

Example: With AssetLoom, teams can be assigned specific views and editing rights. HR can’t change asset specs, but they can assign a laptop to a new hire. IT can’t alter financial records, but they can update asset deployment status.

Fixing disconnected inventory isn’t about buying the most advanced tool. It’s about aligning your processes and people around a shared system. Whether you're a 50-person startup or a growing mid-size business, these steps create clarity, reduce waste, and help every department work smarter together.

=> You can refer to this article to find the right system: Inventory management system

Benefits of Getting Inventory in Sync Between Departments

When inventory systems across departments finally start talking to each other, the difference is immediate and measurable. You eliminate confusion, streamline workflows, and give every team the visibility they need to do their job well.

Here are the key benefits of a connected, cross-department inventory system:

- More Accurate Budgeting and Forecasting: With reliable data from every department, Finance can forecast spend more confidently, avoid budget surprises, and prepare for audits with clean, consistent records.

- Faster Onboarding and Offboarding: HR no longer has to chase IT for equipment or guess what’s available. Assets are assigned, prepared, and tracked with clear handoffs. When someone leaves, their gear is recovered quickly and responsibly.

- Improved Audit Readiness and Compliance: When asset records are centralized and standardized, audits become smoother and less stressful. You’ll know what you own, where it is, and who’s responsible for it.

- Fewer Delays and Reorders: With shared visibility, departments won’t reorder what’s already in stock or wait for updates from another team. You reduce duplication and keep operations moving.

- Greater Accountability and Trust: When each team can see what’s happening and contribute to a shared system, ownership becomes clear. That builds trust and reduces finger-pointing when something goes wrong.

Final Thoughts

Disconnected inventory systems between departments aren’t just inconvenient; they’re costly, frustrating, and entirely fixable.

Every department may have its own way of working, but inventory is a shared responsibility. When tools don’t integrate and teams don’t align, things fall through the cracks. Assets go missing. Purchases get duplicated. Onboarding slows down. Trust erodes.

The good news? You don’t need to overhaul your entire tech stack. You just need to connect the dots; unify your inventory source, standardize your processes, and make sure each team has access to the right data.

Start by asking the simple questions:

- Can every team see the same inventory numbers right now?

- Do they trust those numbers?

- Who owns what and who’s responsible for tracking it?

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox