Integrating Hardware Procurement with IT Asset Management

Learn how integrating hardware procurement with IT asset management boosts efficiency, reduces costs, and streamlines IT operations.

Many IT teams struggle with buying hardware they don’t actually need, replacing devices too late, or managing redundant assets. These issues usually happen because procurement isn’t connected to real-time asset data.

When purchasing decisions are made without insight into existing system and assets, it leads to wasted money, slower operations, and unnecessary stress for IT staff. Every untracked laptop, server, or peripheral adds friction to the workflow.

Connecting hardware procurement with IT asset management (ITAM) addresses these challenges. With accurate asset data guiding purchases, teams can make more informed decisions, control costs, and maximize the use of every device.

This guide will cover practical strategies and real-world scenarios to help your team optimize procurement and stay on top of the IT asset lifecycle.

What is Hardware Procurement in IT?

Hardware procurement is the process of acquiring physical technology assets that your organization needs to operate efficiently and effectively. This includes devices such as laptops, desktops, servers, networking equipment, and other essential hardware. The purpose is not just to buy devices but to ensure the right hardware is available at the right time, in the right quantity, and within budget.

There are different ways hardware procurement happens:

- Planned purchases involve scheduled replacements, upgrades, or equipping new teams. These allow IT teams to plan budgets effectively, negotiate better with vendors, and avoid last-minute rushes.

- Reactive purchases occur when hardware fails unexpectedly or urgent requirements arise. While necessary, these can be more costly and disruptive if not managed carefully.

Effective procurement strategy also considers factors such as cost, warranties, vendor performance, and timing, particularly when managing standard hardware. When paired with IT Hardware Asset Management, teams gain visibility into existing assets, usage patterns, and lifecycle status. This ensures that every procurement decision is strategic, data-driven, and aligned with organizational needs.

Why Integration with ITAM is Critical

When procurement and asset data operate separately, IT teams often make decisions blindly. This can lead to buying hardware that sits idle, missing replacement windows, or rushing purchases that cost more. For example, a team might order new laptops for a project, only to discover that functional devices already exist in storage or that warranties on old devices have expired.

Integration provides visibility into every asset, showing which devices are actively used, underused, or nearing end-of-life. With this insight, IT teams can:

- Avoid redundant purchases by redeploying existing devices.

- Time replacements are strategically planned to prevent downtime and extend asset lifecycles.

- Plan budgets accurately by aligning procurement cycles with actual needs, not guesswork.

- Negotiate better with vendors by knowing volume needs in advance.

In short, integration transforms hardware procurement from a reactive process into a cloud-based, data-driven strategy. IT teams can make informed decisions, reduce costs, and ensure hardware investments truly support business goals.

Step-by-Step Guide to Integrating Hardware Procurement with ITAM

1. Centralize Your Asset Data

Create a single source of truth for all hardware assets, including laptops, desktops, servers, networking equipment, and peripherals. Consolidate information from spreadsheets, procurement systems, and departmental records into one unified platform.

Ensure each asset record captures:

- Location: Where the device is physically located or which department it belongs to.

- User: Who is assigned to the device?

- Condition: Track if it’s in use, idle, or in need of repair.

- Warranty and Support: Document expiration dates and vendor details.

- Lifecycle Stage: Include purchase date, expected end-of-life, and replacement schedule.

Why this matters: Centralizing asset data allows IT teams to see what assets are available, identify underused devices, and plan replacements. It prevents duplicate purchases and supports data-driven procurement decisions.

Practical Tip: Use an ITAM platform or CMDB to automate tracking and reporting. Include alerts for upcoming warranty expirations or devices approaching end-of-life.

2. Align Purchases with Asset Lifecycle

Procurement decisions should be informed by asset lifecycle data. Replace devices proactively before they fail, plan upgrades for new projects, and schedule replacements for aging hardware.

Include key lifecycle details in planning:

- End-of-Life Dates: Schedule replacements before devices fail.

- Warranty Expiration: Avoid unexpected support costs.

- Upgrade Requirements: Align new hardware with software or project needs.

Why this matters: Aligning procurement with the asset lifecycle reduces downtime, ensures business continuity, and maximizes the value of every device. It also prevents overspending on assets that could be redeployed.

Practical Tip: Create a lifecycle calendar that tracks upcoming replacements and project-driven upgrades. Review it quarterly to stay ahead of procurement needs.

3. Automate Procurement Workflows

Manual procurement processes are slow, prone to errors, and often disconnected from asset data. Automation ensures approvals, purchase orders, and inventory updates are handled efficiently.

Key elements to automate:

- Purchase Requests: Trigger based on low stock or devices nearing end-of-life.

- Approval Routing: Ensure requests go through proper channels automatically.

- Inventory Updates: Keep asset records synchronized with procurement actions.

Why this matters: Automation reduces errors, speeds up procurement, and ensures alignment with asset availability. Teams can respond faster to urgent needs while maintaining accurate records.

Practical Tip: Integrate procurement software with your ITAM system so any new purchase automatically updates the asset inventory and lifecycle data.

4. Monitor Usage and Inventory Regularly

Procurement strategy decisions should be based on how assets are actually used, not assumptions about their standard hardware utilization. Track asset usage to identify underutilized devices and prevent unnecessary purchases.

Important monitoring points:

- Asset Utilization: Identify idle or rarely used devices.

- Department Allocation: Ensure resources are distributed according to actual need.

- Inventory Levels: Maintain optimal stock to prevent shortages or overstock.

Why this matters: Regular monitoring helps reduce waste, improve asset utilization, and inform smarter budget planning. It ensures procurement is based on actual business needs.

Practical Tip: Use dashboards and reports to visualize asset usage trends. Share insights with department heads to coordinate redeployment before buying new hardware.

5. Leverage Insights for Strategic Procurement Decisions

Use historical data, usage trends, and lifecycle reports to make informed procurement choices. Decide not just what to buy, but when, how much, and from which vendor.

Insights to consider:

- Past Purchase Trends: Understand which assets are frequently replaced or fail early.

- Device Performance: Identify hardware that consistently meets or fails business requirements.

- Departmental Needs: Adjust quantities based on project expansions or team growth.

Why this matters: Data-driven decisions improve ROI, avoid overstocking, and ensure procurement aligns with real business demand. Vendors can also be negotiated with confidence, knowing precise requirements.

Practical Tip: Analyze usage and procurement data quarterly to identify opportunities for bulk purchasing or strategic vendor contracts.

6. Integrate Procurement with Budget Planning

Procurement should be aligned with IT budgets and financial forecasts to control costs effectively. Consider not just purchase price, but total lifecycle cost, including maintenance, support, and disposal.

Steps to integrate with budgeting:

- Map Procurement Cycles: Align hardware purchases with quarterly or annual budgets.

- Factor Depreciation: Include lifecycle costs in financial planning.

- Forecast Needs: Use asset and usage data to anticipate upcoming expenditures.

Why this matters: Integrating procurement with budgets prevents overspending, ensures funds are allocated strategically, and supports long-term IT financial planning.

Practical Tip: Coordinate with finance teams regularly to review upcoming procurement needs and adjust budget allocations based on actual asset data.

7. Continuously Review and Improve the Process

Hardware procurement and asset management are ongoing activities. Regularly review procurement outcomes, identify inefficiencies, and refine processes to improve efficiency.

Key review points:

- Post-Procurement Audits: Verify that purchases matched real needs.

- Feedback from IT Teams: Understand challenges in usage, deployment, or approvals.

- Process Adjustments: Update workflows, automation rules, and policies as business needs evolve.

Why this matters: Continuous improvement ensures procurement remains efficient, cost-effective, and aligned with evolving organizational goals.

Practical Tip: Schedule annual or semi-annual process reviews. Track KPIs like cost savings, asset utilization, and procurement cycle time to measure improvement.

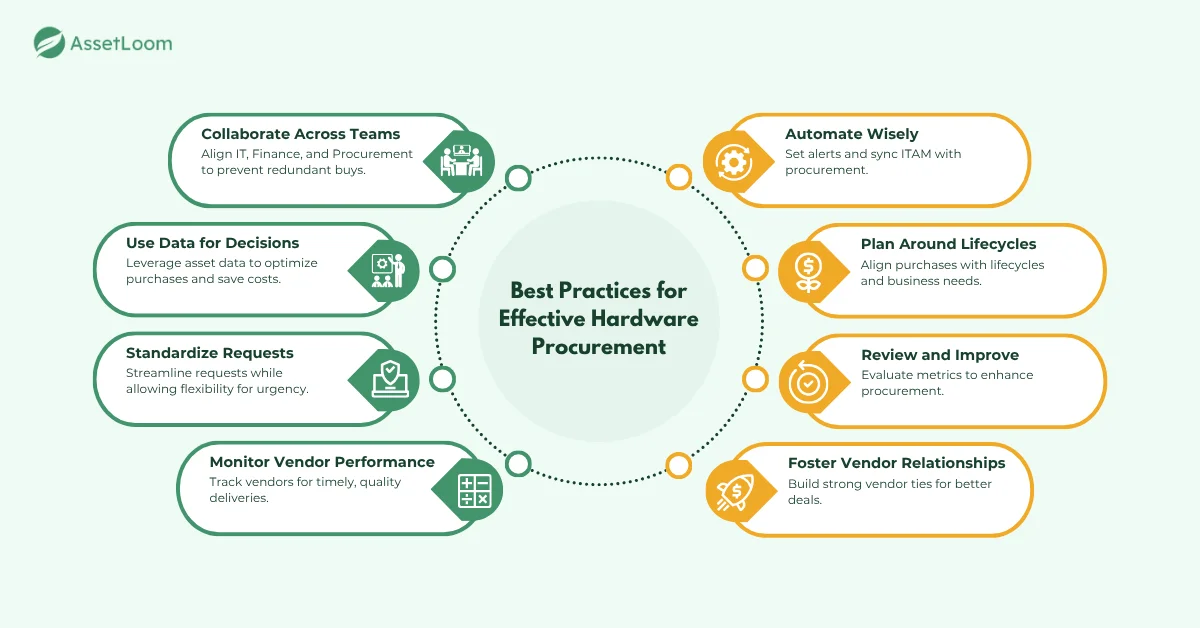

Best Practices for Effective Hardware Procurement

Collaborate Across Teams

Hardware procurement isn’t just an IT job. Finance, procurement, and IT need to work together to make sure purchases fit budgets, project timelines, and real asset needs. Schedule regular check-ins to review upcoming requirements. This simple step can prevent buying devices you already have in storage.

Make Decisions Based on Data

Avoid guessing. Use real asset data to guide purchases. Look at device age, usage patterns, and replacement schedules. If some laptops are underused, redeploy them instead of buying new ones. Data-driven decisions help save costs and prevent unnecessary purchases.

Standardize Requests, But Stay Flexible

A clear process for submitting and approving hardware requests reduces errors and speeds approvals. Include required details like department, asset type, and priority. At the same time, allow a fast-track option for urgent requests. This keeps things organized without slowing business operations.

Monitor Vendor Performance

Suppliers can make or break your procurement process. Track delivery times, quality, and pricing. If a vendor frequently delivers late, use the data to renegotiate terms or choose a different supplier. This ensures timely deliveries and consistent quality.

Use Automation Wisely

Automation can save time, but it should complement human oversight. Set up alerts for low stock, devices approaching end-of-life, or expiring warranties. Integrate your ITAM system with procurement tools so your asset data updates automatically. This helps avoid buying hardware you don’t need.

Plan Around Lifecycle and Projects

Procurement is not just about replacing old hardware. Plan purchases around business initiatives and device lifecycles. Schedule upgrades before devices fail, coordinate bulk purchases for new teams, and ensure warranties cover critical operations. Proactive planning keeps IT running smoothly.

Review, Learn, and Improve

Hardware procurement is an ongoing process. Regularly check metrics like cost per asset, procurement cycle time, and asset utilization. Are some departments overstocked? Are emergency purchases common? Use these insights to refine workflows and policies. Continuous improvement keeps procurement efficient and aligned with business needs.

Foster Vendor Relationships

Building strong, long-term relationships with vendors can lead to better deals, faster deliveries, and prioritized customer support. Effective vendor management through regular communication ensures smoother procurement processes and stronger partnerships

KPIs for Measuring Procurement Success

Measuring the success of hardware procurement is crucial to ensuring your strategies are effective and your resources are being utilized optimally. By tracking key performance indicators (KPIs), you can evaluate your procurement process, identify areas for improvement, and make informed decisions for future purchases.

Procurement Cycle Time

Procurement cycle time measures the time it takes from the initiation of a hardware request to the final purchase and delivery. A shorter cycle time means more efficient procurement, helping IT teams avoid delays and reduce the impact of device shortages or failures. To track this KPI, record the date of the purchase request and monitor the time until the hardware is delivered.

Cost Per Asset

Cost per asset calculates the total cost of procuring an individual hardware asset, including purchase price, delivery, setup, and maintenance. Understanding the cost of each asset helps track spending and ensures procurement stays within budget. It also allows teams to identify cost-saving opportunities, such as bulk purchases or negotiating better vendor contracts. To track this KPI, divide the total procurement costs by the number of assets procured during a specific period.

Asset Utilization Rate

Asset utilization rate looks at the percentage of assets that are actively in use versus those that are idle. High asset utilization means your hardware investments are being put to good use. Low utilization could indicate over-purchasing, under-deployment, or the need for redistribution of assets. This can be tracked by using asset management software to monitor how often each asset is used, helping to determine whether any hardware is underutilized or needs to be redeployed.

On-Time Delivery Rate

On-time delivery rate measures the percentage of hardware deliveries that arrive on time, according to the original procurement plan. Timely deliveries are critical to avoiding delays in project deadlines or system upgrades. A low on-time delivery rate could signal issues with vendors or procurement planning. To track this, monitor the delivery dates against the agreed-upon dates with vendors, identifying any recurring issues or delays.

Vendor Performance

Vendor performance assesses the reliability and quality of vendors based on factors such as delivery times, product quality, and support. Strong vendor performance leads to better procurement deals, quicker deliveries, and smoother project implementations. Poor vendor performance, on the other hand, can disrupt operations and cost your business more in the long run. To track this, maintain a vendor scorecard, tracking delivery accuracy, product quality, and after-sales service. Analyzing this data will help guide future vendor selection.

Budget Adherence

Budget adherence looks at the degree to which procurement expenses stay within the planned budget. Adhering to the budget is a key indicator of procurement efficiency. If the budget is consistently exceeded, it could suggest issues with planning, purchasing processes, or vendor management. To track this, compare actual procurement spending against the allocated budget on a quarterly or annual basis.

Return on Investment (ROI)

Return on investment (ROI) evaluates the financial return or productivity gain from the hardware investment. It’s important to assess whether hardware purchases are delivering the expected benefits, such as improved employee productivity, system performance, or cost savings. To track ROI, calculate the total benefits from hardware purchases (such as productivity gains or cost savings) and compare them to the total procurement costs.

Why These KPIs Matter

By regularly tracking and analyzing these KPIs, IT teams can make more informed decisions, ensuring that every procurement process is aligned with organizational goals. These metrics will not only help streamline operations but also pinpoint areas that require improvement, helping to avoid overspending, prevent procurement delays, and ensure hardware investments are working as intended.

Practical Tip: Use procurement and ITAM software to track these KPIs in real time. Dashboards and automated reports can provide immediate insights, allowing you to make adjustments swiftly and efficiently.

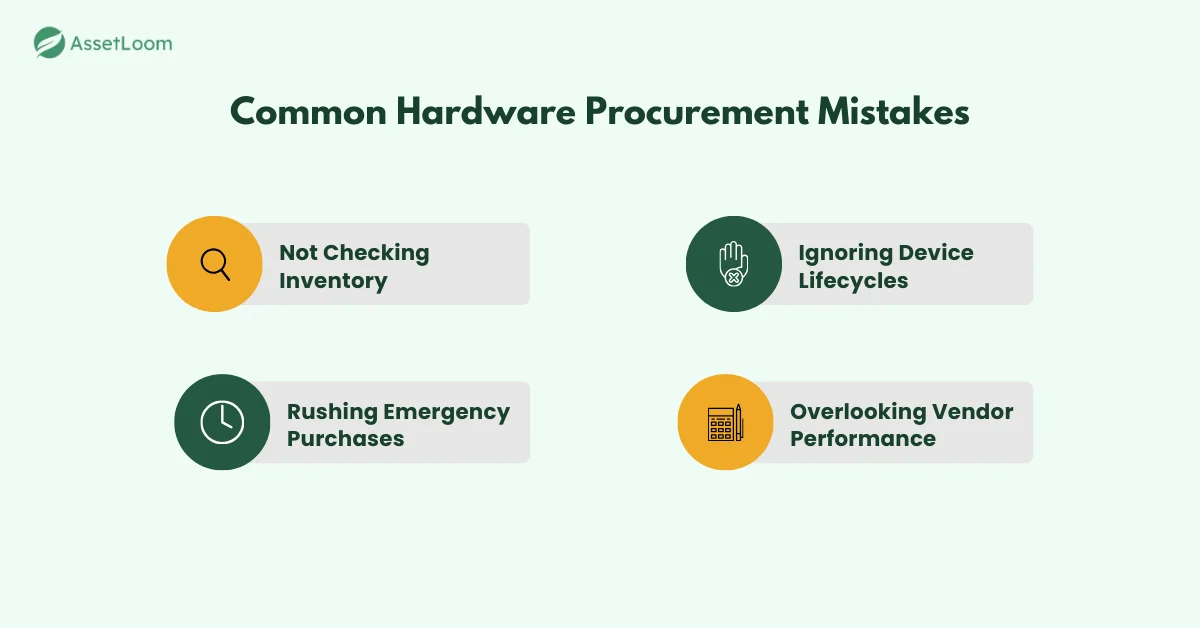

Watch Out for Common Hardware Procurement Mistakes

Even experienced IT teams can fall into the same traps. Being aware of them can save time, money, and headaches.

- Ordering Without Checking Inventory: Buying new devices without knowing what you already have can lead to redundant purchases and wasted budgets.

- Ignoring Hardware Lifecycles: Replacing hardware too early or waiting too long can cause downtime or unnecessary costs. Always plan around lifecycle data.

- Rushing Reactive Purchases: Emergency replacements are sometimes unavoidable, but last-minute buys usually cost more and disrupt operations.

- Neglecting Vendor Performance: Not tracking supplier reliability, delivery times, or quality can create delays and extra expenses down the line.

By avoiding these common mistakes, your team can make smarter procurement decisions and keep IT running smoothly.

Make Hardware Procurement Smarter

Avoiding common procurement mistakes is just the first step. When you combine awareness of these pitfalls with best practices - like centralizing asset data, aligning purchases with device lifecycles, leveraging automation, and regularly reviewing performance - you can turn hardware procurement into a strategic and efficient process.

Taking a data-driven, proactive approach helps your IT team reduce overspending, prevent downtime, and get the most out of every asset. Start applying these strategies today, and you’ll see procurement become smoother, smarter, and more aligned with your organization’s goals.

Frequently Asked Questions

1. How can I avoid over-purchasing hardware?

By integrating your hardware procurement with IT asset management (ITAM), you can track device usage and lifecycle data. This allows you to make informed decisions about what to buy, redeploy unused assets, and avoid unnecessary purchases.

2. What role does vendor performance play in procurement?

Vendor performance directly impacts the timeliness and quality of your hardware deliveries. By tracking vendor metrics, you can negotiate better deals, ensure faster deliveries, and avoid disruptions in your procurement process.

3. How do I ensure hardware purchases align with company needs?

Planning around your IT asset lifecycle and upcoming projects is key. By aligning procurement with device lifecycles and business initiatives, you ensure you’re purchasing what’s needed when it’s needed, without overbuying or understocking.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.