Incorporating Asset Management: Car Repair Shop Case Studies

Discover how small, growing, and large car repair shop boost efficiency and profits by incorporating asset management.

What’s it like when managing a car repair shop?

Well, we all know that there are not only cars, but hundreds and thousands of other tools, from tiny to large, for you to manage. We all also know that losing any of those tools can lead to troubles, even big ones: costing replacement money, interrupting workflow, unhappy customers, to name a few. Managing a car repair shop is no easy task.

That’s the reason why incorporating asset management and car repair shop should be prioritized. This approach isn’t just for big corporations; it’s a practical strategy that can transform how your shop operates, saving you time, money, and stress.

To show how this works in practice, let’s explore three fictional case studies of car repair shops—a small shop, a growing shop, and a large shop, that transformed their businesses by adopting asset management. These stories offer practical steps and real results to inspire your own journey.

Case Study 1: The Small Car Repair Shop

The Challenge

The small car repair shop, a family-run business with two bays and three technicians, faced constant chaos. The owner struggled with misplaced tools and unexpected equipment breakdowns. Technicians wasted time searching for wrenches or waiting for the diagnostic scanner, slowing down repairs. Customers noticed longer wait times, and profit margins shrank due to rushed, costly inventory orders.

The Solution

The owner decided to incorporate asset management into the car repair shop using a simple, affordable asset management tool. Here’s how they tackled the problem:

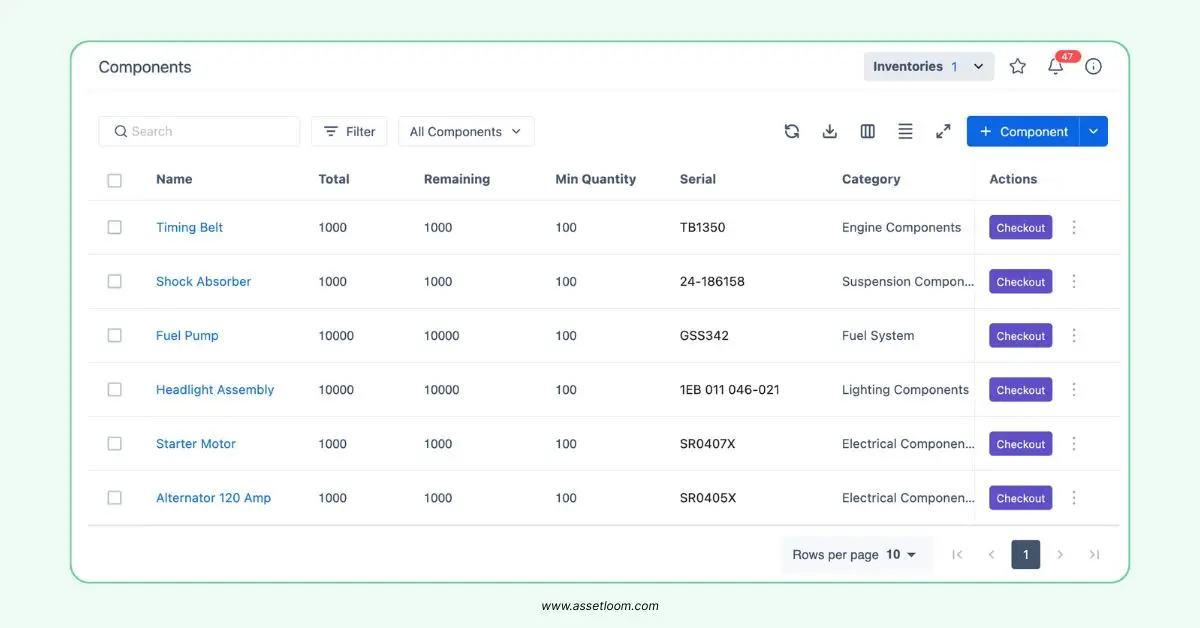

- Cataloged Assets: The team listed all tools, equipment, and spare parts, noting their condition and location.

AssetLoom helps car shops manage all tools, equipments, and spare parts

- Tagged Items: They used QR code stickers to label high-value items like the tire balancer and diagnostic scanners, linking them to the software.

- Scheduled Maintenance: The system sent reminders for equipment servicing, such as calibrating the alignment machine every six months.

- Managed Inventory: The owner set reorder points for fast-moving parts like oil filters to avoid stockouts during busy days.

Related article: What is an IT Asset Management Tool and Why Do You Need One?

The Results

Within three months, the small shop reduced downtime by 25%. Technicians scanned QR codes to find tools instantly, speeding up repairs. Preventive maintenance halved equipment failures, saving $1,500 in emergency repairs. Inventory costs dropped 10% by eliminating overstocking. Customers appreciated faster service, leading to better online reviews and more business. The owner now spends less time troubleshooting and more time planning for growth.

Key Takeaway

For small shops, incorporating asset management into your car repair shop can be simple and effective. A basic system, clear organization, and team commitment deliver big results.

Case Study 2: The Growing Car Repair Shop

The Challenge

The growing car repair shop, with five bays and eight technicians, was thriving but struggling to keep pace. Inventory was disorganized - parts were often misplaced, causing delays. Expensive tools, like a $5,000 diagnostic scanner, went missing for days. Without a maintenance schedule, hydraulic lifts broke down unexpectedly. The owner needed a system to support the shop’s expansion without losing control.

The Solution

The owner chose to incorporate asset management into the car repair with AssetLoom, an ITAM software that can help keep track of any items. Their approach included:

- Centralized Tracking: The owner uploaded all assets into AssetLoom, creating a digital dashboard to monitor tools, equipment, and inventory.

- Team Training: A training session showed technicians how to log tool usage and report issues via the software’s mobile app.

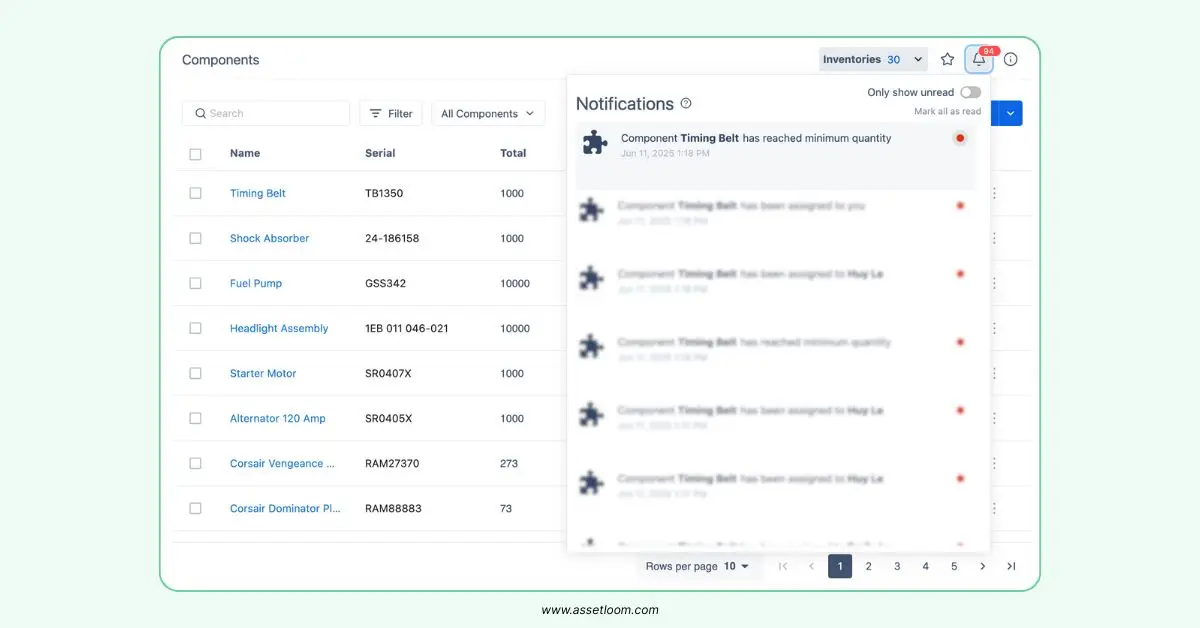

- Automated Inventory: AssetLoom tracked stock levels for parts like brake pads and alerted the owner when supplies were low, syncing with suppliers for quick reordering.

- Data Insights: Reports identified underperforming assets, like an outdated air compressor slowing down tire services.

The Results

Six months after adopting asset management, the growing shop ran smoothly. Tool misplacement dropped by 80% with app-based tracking. Inventory delays nearly vanished, saving $2,000 monthly in rush orders. Replacing the old air compressor cut tire repair times by 15 minutes per job, allowing more customers daily. Revenue grew by 20%, and the owner hired two new technicians. The team appreciated the streamlined workflow, boosting morale.

Key Takeaway

For expanding shops, incorporating asset management into your car repair shop supports growth. A robust system with mobile access and data insights keeps operations efficient as demand rises.

Case Study 3: The Large Car Repair Shop – Unifying Multiple Locations

The Challenge

The large car repair shop, a chain with three locations, was losing money due to inconsistency. Each shop had different tools, inventory levels were unpredictable, and equipment breakdowns were frequent. One location’s lift was out for a week, costing $3,000 in lost revenue. The manager needed a unified system to align all locations and restore profitability.

The Solution

The manager decided to incorporate asset management into the car repair shop using a customizable platform that synced data across multiple sites. Their strategy included:

- Standardized Asset Lists: The manager created a master inventory for all three locations, ensuring each had consistent tools and parts.

- Cross-Location Tracking: cloud asset management software allowed the manager to see assets across all shops, enabling tool sharing, like specialty scanners, when needed.

- Preventive Maintenance Plans: Maintenance schedules were set for equipment, like quarterly lift servicing, and tracked in the software.

- Cost Monitoring: Reports identified wasteful spending, such as duplicate part orders, and streamlined purchasing.

The Results

After a year, the large shop turned profitable for the first time in two years. Equipment downtime fell by 60%, saving $10,000 annually in repairs and lost revenue. Standardized inventory reduced overstock by 30%, freeing $15,000 in cash flow. Sharing assets between locations avoided unnecessary purchases, like a second $4,000 scanner. Customer wait times dropped, boosting repeat business by 15%. The chain is now planning a fourth location.

Key Takeaway

For multi-location shops, incorporating asset management into your car repair shop ensures consistency and cost savings. A centralized system keeps all sites aligned and efficient.

Why These Shops Succeeded

These case studies show that incorporating asset management into your car repair shop works for businesses of all sizes: small, growing, or large. Here’s what drove their success:

- Tailored Systems: Each shop chose software that matched their scale—simple for the small shop, robust for the growing shop, and multi-site for the large shop.

- Team Engagement: Training staff ensured smooth adoption and reduced resistance.

- Data-Driven Decisions: Reports helped owners identify issues, like wasteful spending or slow equipment, and act quickly.

- Proactive Maintenance: Regular servicing kept tools and machines reliable, avoiding costly breakdowns.

How to Apply These Lessons to Your Shop

Ready to transform your shop? Here’s a quick plan to incorporate asset management into your car repair shop:

- Evaluate Your Scale: Are you a small, growing, or large shop? Choose a system that fits your needs.

- Start Small: Focus on high-impact assets, like diagnostic tools or fast-moving parts, and expand gradually.

- Pick the Right Tool: Try EZOfficeInventory, AssetLoom, or Asset Panda, most offer free trials to test compatibility.

- Train Your Team: Show staff how the system saves time and make it part of daily routines.

- Track Progress: Review reports monthly to monitor savings, downtime, and customer satisfaction.

Final Thoughts

Incorporating asset management car repair shop is a practical way to boost efficiency, cut costs, and delight customers. Whether you’re running a small operation, scaling up, or managing multiple locations, these case studies show what’s possible. The small shop saved time, the growing shop scaled smoothly, and the large shop unified its operations, all by tracking assets smartly.

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox