How Warranty Check Cuts IT Replacement Costs

Discover how warranty checks prevent unnecessary IT replacements, save costs, and extend the value of your business assets.

Replacing IT equipment is one of the biggest costs for any business. The problem is, many replacements happen far earlier than they should. A laptop crashes, a server stops responding, or a piece of networking gear slows down, and the quick solution is to order a new one.

What often gets missed is that many of these assets are still under warranty. Instead of being repaired or replaced at no cost, companies spend thousands on brand-new devices they didn’t actually need.

This oversight drains IT budgets and shortens the life of valuable assets. In this blog, we’ll look at why warranty checks are often overlooked, how they impact replacement costs, and how building them into your IT asset management process can lead to real savings.

The Costly Scenario Businesses Overlook

Picture this. An IT team replaces a fleet of servers after a failure, spending tens of thousands of dollars to keep operations running. A few weeks later, they discovered those same servers were still under warranty. The repair or even full replacement could have been handled at no additional cost.

Situations like this are more common than most businesses realize. Without visibility into warranty status, IT teams often make decisions based on urgency rather than facts. The result is money lost on unnecessary purchases, strained budgets, and shorter-than-necessary asset lifecycles.

Take laptops as an example. Replacing 50 units at $1,200 each quickly adds up to $60,000. If those laptops were still covered by warranty, the same issue might have been resolved for nothing. Multiply that across servers, networking gear, and other devices, and the hidden cost of missed warranty checks becomes enormous.

Skipping warranty checks doesn’t just waste money. It also creates a pattern where replacement becomes the default solution, even when better options exist.

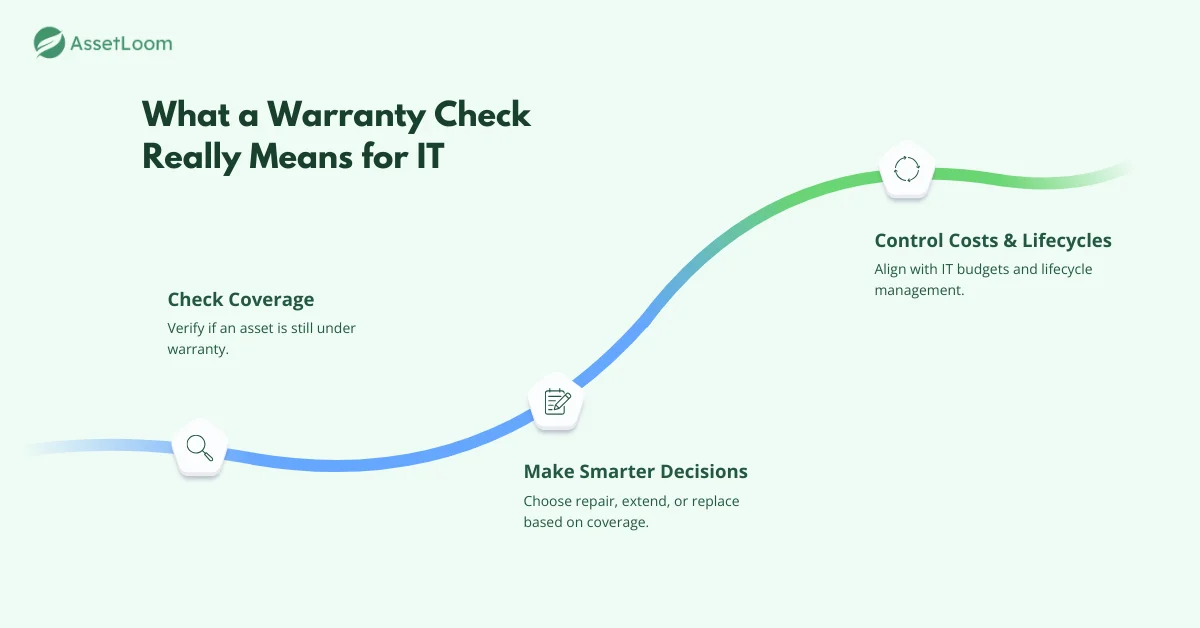

What a Warranty Check Really Means for IT

A warranty check is the process of verifying whether an asset is still covered by its manufacturer or vendor warranty before deciding on repair or replacement. It may sound simple, but for IT teams managing thousands of devices, it can make a big difference.

Instead of relying on assumptions or outdated records, a warranty check provides accurate information about coverage. This allows IT managers to make smarter choices: repair under warranty when possible, plan replacements only when coverage has ended, and align these decisions with overall IT asset lifecycle management.

In practice, warranty checks are less about paperwork and more about enabling IT to spend wisely, protect budgets, and extend the useful life of business-critical assets. When part of a structured warranty management process, they become a reliable tool for cost control and decision-making.

Why Warranty Data Often Goes Missing

Warranties can prevent unnecessary IT spending, yet they are rarely tracked effectively. The issue is not that IT teams don’t value warranties, but that warranty data is often fragmented and hard to access when it’s needed most.

One reason is the way information is stored. Warranty details typically sit in different places — vendor portals, purchase receipts, emails, or manufacturer databases. Without a single source of truth, IT teams spend valuable time searching across systems. In fast-moving situations, like a server outage, there’s rarely time to dig through this scattered data.

Another common issue is asset ownership. Devices often move between departments or locations, and warranty information doesn’t always follow. A laptop bought by the finance team, for example, may later be reassigned to HR, but its warranty record stays buried in finance’s files.

Finally, manual tracking methods make things worse. Spreadsheets are prone to human error, easily outdated, and rarely include automated reminders for upcoming warranty expirations. This means warranties quietly expire or get ignored until it’s too late.

The result of all these gaps is clear: businesses miss opportunities to use existing coverage, leading to avoidable repair bills and premature replacements.

How Warranty Checks Reduce Replacement Costs

Replacing IT equipment is one of the biggest ongoing costs for any organization. What many don’t realize is that a large part of these expenses can be avoided by making warranty checks part of the IT process. A warranty check may seem like a small step, but it has a big influence on costs, asset value, and overall IT strategy.

Repairs Instead of New Purchases

When a device breaks down, the quick reaction is often to replace it. But if that device is still covered, vendors will usually repair or replace it at no additional cost. For example, a failed $15,000 server could be fixed by a free component swap under warranty. What would have been a large capital expense instead becomes a covered repair.

Extending the Asset Lifecycle

Assets like laptops, servers, and networking gear are often retired long before they reach the true end of life. Warranty checks prevent this by ensuring minor issues are fixed under coverage, keeping equipment in use longer. This reduces the frequency of refresh cycles and allows organizations to squeeze more value out of their existing investments.

Improving Budget Accuracy

Unplanned replacements create spikes in IT spending. By factoring warranty coverage into decisions, IT leaders can plan purchases more accurately. Instead of setting aside funds for premature replacements, budgets can be reserved for genuine end-of-life assets, improving cost predictability year over year.

Avoiding Emergency Purchases

Unexpected equipment failures often lead to rushed replacement orders, which are usually more expensive and disruptive. With warranty checks, IT teams can turn to vendor support immediately, reducing downtime and avoiding the premium costs of emergency purchases.

Contributing to Sustainability Goals

Repairing instead of replacing not only saves money but also reduces e-waste. For companies tracking ESG or sustainability metrics, extending the lifecycle of devices through warranty coverage supports both financial and environmental targets.

In practice, warranty checks shift IT thinking from “replace immediately” to “confirm coverage first.” This small change helps organizations cut replacement costs, maximize asset value, and plan IT spending with far greater confidence.

Automating Warranty Checks at Scale

Checking warranties by hand might be manageable for a small office with a few dozen devices. But for most organizations, IT teams are responsible for hundreds or even thousands of assets across different locations. Spreadsheets and email records can’t keep up, and the result is missed coverage and unnecessary spending.

This is where automation makes the difference. Instead of chasing down serial numbers or logging into multiple vendor portals, automation pulls warranty details from manufacturers directly into one system. IT managers can see, at a glance, which devices are still covered and which are approaching expiration.

The real value comes from what automation enables. With real-time updates, warranty data is always accurate. With alerts, IT teams can act before coverage ends, either by extending a contract or planning a replacement. And because the process runs in the background, IT staff don’t have to spend hours on manual checks; they can focus on higher-value work.

For large enterprises, automation also brings consistency. A device in a remote office gets the same level of visibility as one in headquarters. No matter where an asset lives in the organization, IT leaders know its warranty status and can make informed decisions about repairs and replacements.

Automation doesn’t just make warranty checks faster. It makes them practical, scalable, and reliable, turning what used to be a manual chore into a routine part of smart IT asset management.

Beyond Cost: Additional Benefits of Warranty Checks

While cost savings are the most visible result of warranty checks, their value reaches much further. When warranties are actively tracked, audits become less stressful because coverage records are easy to access and prove. IT leaders also gain better visibility into when assets will actually need replacement, which makes budget planning and vendor negotiations more predictable.

There’s another dimension too — sustainability. Every device that gets repaired under warranty instead of replaced early reduces electronic waste. For organizations working toward ESG targets, this is a simple but powerful way to show progress.

So, warranty checks are not just about saving money today. They also build confidence in compliance, improve long-term planning, and support broader business goals like sustainability.

Conclusion

Replacing IT equipment is unavoidable, but replacing it too soon is costly. A quick warranty check can turn a major expense into a covered repair, extend the life of assets, and keep IT budgets under control.

When integrated into IT asset management and supported by automation, warranty checks go beyond cost savings. They improve compliance, strengthen planning, and even support sustainability efforts.

The next time a replacement request lands on your desk, check the warranty first. It may save more than you expect.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.