Best Software for Manufacturing Companies: The Must-Have Tools for Industry 4.0

Discover the best software for manufacturing companies and the must-have tools driving Industry 4.0. Boost efficiency and stay competitive.

Manufacturing is changing fast. Legacy systems can’t keep up with rising costs, supply chain complexity, and the demand for real-time data. If your operations still rely on outdated tools, you’re already losing ground.

Industry 4.0 is here - powered by AI, IoT, and smart automation - and it’s transforming how factories run. The right software isn’t just a convenience anymore; it’s the difference between leading the market and falling behind.

In this article, we’ll break down the best software for manufacturing companies in 2025 and show you which tools can drive efficiency, reduce downtime, and future-proof your operations.

What is Industry 4.0?

Manufacturing isn’t what it used to be. Gone are the days when success depended on heavy machines and manual oversight. Today, the real power lies in data, connectivity, and automation, and that’s exactly what Industry 4.0 is all about.

Think of Industry 4.0 as the next big leap in manufacturing. It’s the move from traditional factories to smart factories, where every machine, sensor, and system talks to each other. This connectivity turns your entire operation into a single intelligent network.

Here’s what makes Industry 4.0 a game-changer:

- Connectivity: Machines and sensors share real-time data through IoT, so you’re never guessing what’s happening on the shop floor.

- AI in Action: Algorithms predict maintenance needs, optimize workflows, and help you make better decisions before problems even occur.

- Big Data: Every click, every reading, every production metric is captured and analyzed to improve efficiency and reduce waste.

- Smarter Automation: Robots and humans work side by side, combining precision with adaptability.

Why does it matter? Industry 4.0 gives manufacturers the agility to compete in an unpredictable world. Faster decisions, fewer errors, and lower costs. This is the new standard.

Why Software is the Backbone of Industry 4.0

You cannot build a smart factory with hardware alone. Machines and sensors might look impressive, but without the right manufacturing management software, they are just expensive pieces of metal.

Manufacturing today is like managing a living organism where every process depends on another. One small delay on the production line can ripple through your entire supply chain. Many manufacturers still rely on outdated systems that cannot keep up.

The real problems without modern software:

- Blind Spots Everywhere: You do not know about a bottleneck until it hits.

- Slow Response: By the time reports come in, the damage is already done.

- Disconnected Data: Your ERP, MES, and IoT devices all speak different languages.

Modern software solves these problems. It connects machines, people, and processes into one intelligent network. It does not just track what is happening; it predicts problems, automates decisions, and keeps your factory running like clockwork.

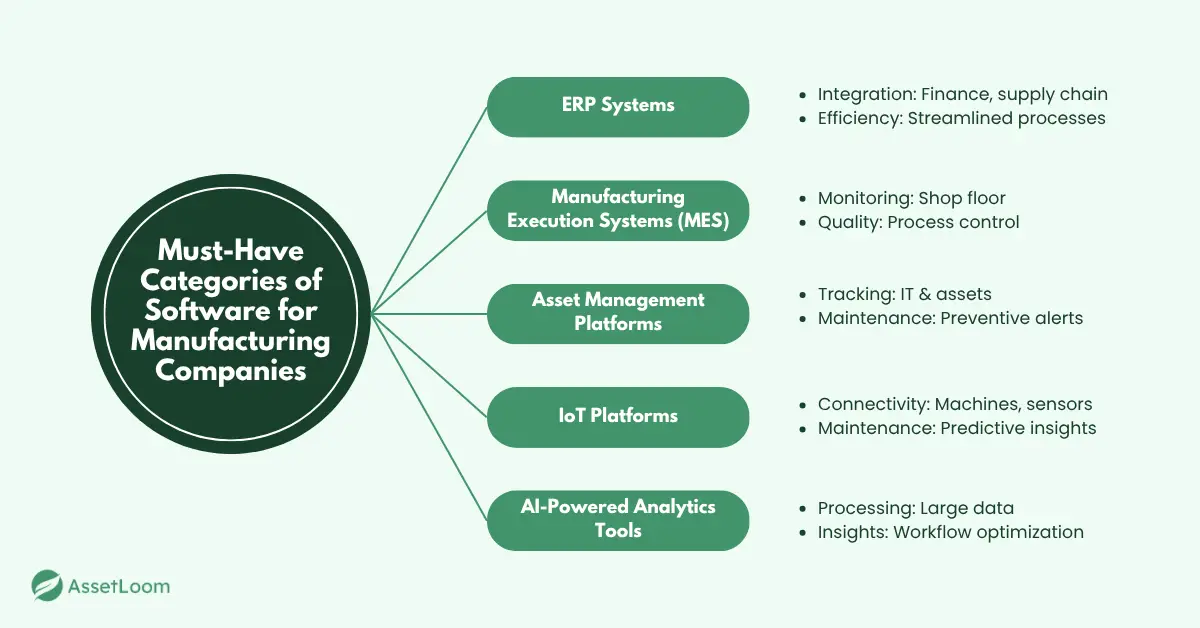

Must-Have Categories in the Best Software for a Manufacturing Company

To thrive in Industry 4.0, manufacturers need more than one tool. Here are the core software categories every modern factory should consider:

1. ERP Systems

Enterprise Resource Planning (ERP) software integrates core business functions such as finance, supply chain, and production planning into one platform. It ensures smoother operations and better resource allocation.

Why it matters: A robust ERP system gives you a single source of truth across all departments, reducing errors and streamlining decision-making.

2. Manufacturing Execution Systems (MES)

MES software manages and monitors shop floor operations in real time. It improves production visibility, quality control, and compliance.

Why it matters: It bridges the gap between planning and execution, ensuring every process runs on time and at the right quality standard.

3. Asset Management Platforms

These platforms help track, maintain, and optimize both IT and physical assets. They reduce downtime, extend equipment life, and improve cost efficiency.

Why it matters: Strong asset management can significantly lower maintenance costs and prevent unexpected failures that disrupt production.

4. IoT Platforms

IoT platforms connect machines, sensors, and devices to collect real-time data. They enable predictive maintenance and smarter decision-making through connectivity.

Why it matters: Real-time IoT data helps you identify issues before they become critical, improving uptime and reducing operational risks.

5. AI-Powered Analytics Tools

AI-driven analytics tools process large volumes of data for predictive insights. They help identify patterns, prevent issues, and optimize workflows.

Why it matters: AI turns raw production data into actionable insights, enabling proactive decisions that boost efficiency and cut costs.

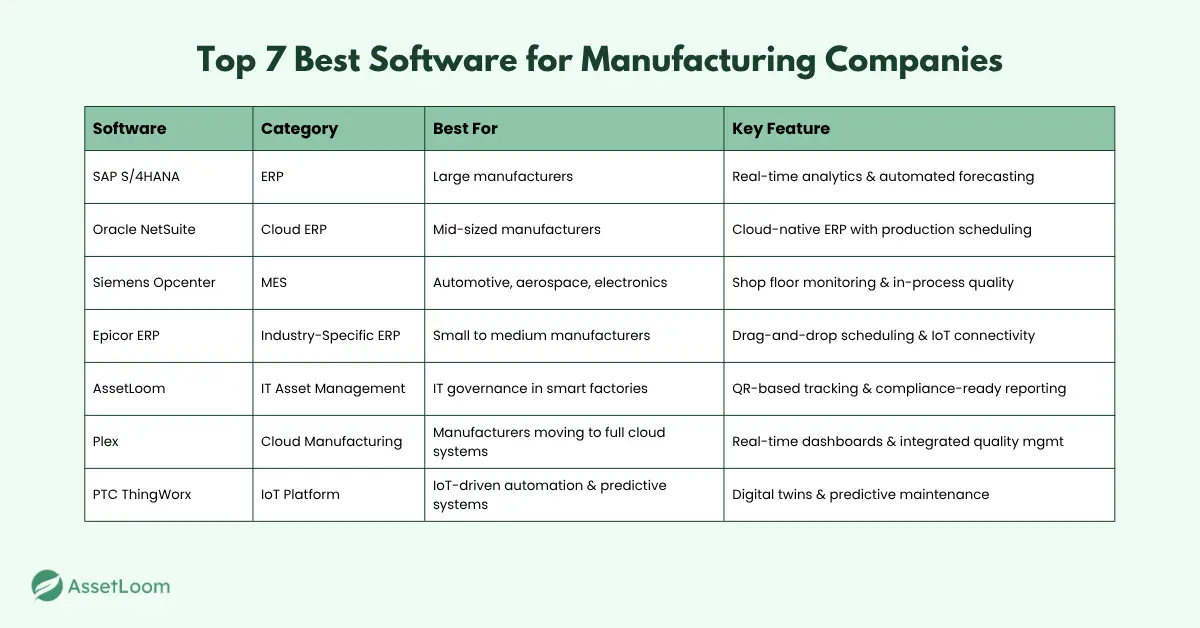

Top 7 Best Software for Manufacturing Companies

Choosing the right tools can transform your operations. Below are the best solutions available in 2025, each excelling in its category.

1. SAP S/4HANA

Category: ERP

SAP S/4HANA is a leading enterprise resource planning system that centralizes operations and provides real-time insights for large-scale manufacturers.

Key Features:

- In-memory computing for instant analytics

- Integrated supply chain and production planning

- Automated demand forecasting and cost control

Best For: Large manufacturers handling complex global operations with high-volume data.

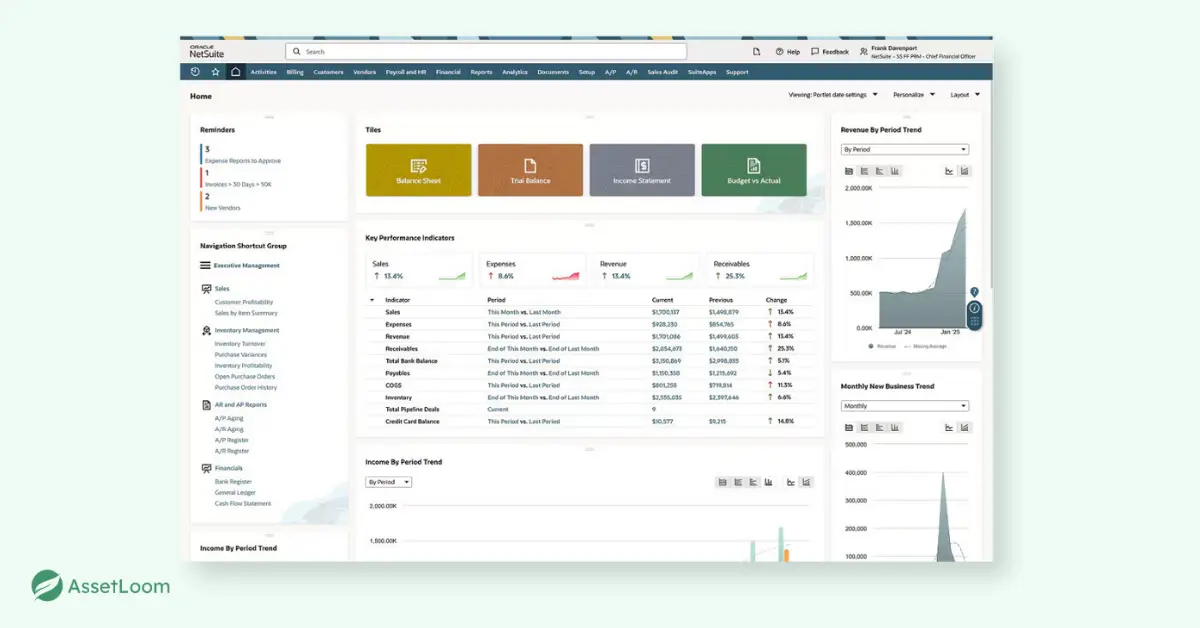

2. Oracle NetSuite

Category: Cloud ERP

Oracle NetSuite offers a cloud-based ERP platform ideal for mid-sized manufacturers that want scalability without heavy IT overhead.

Key Features:

- Real-time inventory tracking with automatic stock updates

- Built-in production scheduling and work order management

- Cloud-native architecture for rapid deployment and easy scaling

Best For: Mid-sized manufacturers looking for quick implementation and flexibility.

Source: Oracle NetSuite, 2025.

3. Siemens Opcenter

Category: MES

Siemens Opcenter gives manufacturers real-time visibility into shop floor operations and ensures quality compliance for high-complexity environments.

Key Features:

- Real-time monitoring of machine and operator performance

- Automated in-process quality checks

- Compliance reporting for regulated industries

Best For: Manufacturers in sectors like automotive and aerospace with strict quality requirements.

4. Epicor ERP

Category: Industry-Specific ERP

Epicor ERP delivers manufacturing-focused solutions with IoT readiness and flexible deployment for small to medium-sized businesses.

Key Features:

- Drag-and-drop production scheduling interface

- IoT connectivity for real-time machine data collection

- Configurable dashboards for financial and shop floor insights

Best For: SMBs needing a customizable ERP that supports modern smart factory initiatives.

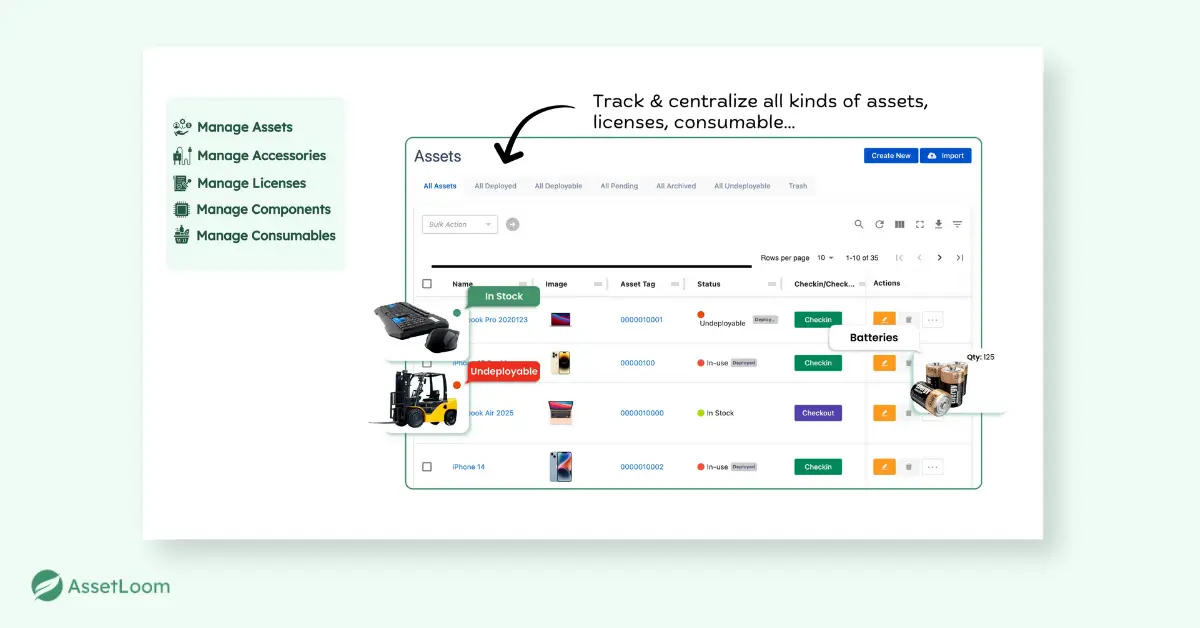

5. AssetLoom

Category: IT Asset Management

AssetLoom gives manufacturers complete visibility and control over IT assets across multiple locations, ensuring compliance and minimizing downtime.

Key Features:

- Live asset tracking with QR code-based identification

- Automated preventive maintenance alerts and schedules

- Advanced reporting tools for audit and compliance readiness

- Role-based access with secure cloud integration

Best For: Manufacturers requiring strict IT asset governance and streamlined maintenance in smart factories.

6. Plex Smart Manufacturing Platform

Category: Cloud Manufacturing

Plex offers a unified platform for production control, inventory management, and quality assurance, all in the cloud.

Key Features:

- Real-time production monitoring with automated reporting

- Integrated quality management with defect tracking

- Cloud-based dashboards for remote performance visibility

Best For: Manufacturers seeking an all-in-one solution for operations and quality control without on-premise infrastructure.

7. PTC ThingWorx

Category: IoT Platform

PTC ThingWorx enables manufacturers to create connected factories through IoT integration, predictive analytics, and digital twins.

Key Features:

- Real-time connectivity between machines and sensors

- Predictive maintenance powered by data-driven insights

- Digital twin technology for process simulation and optimization

Best For: Manufacturers prioritizing IoT connectivity and predictive capabilities for Industry 4.0.

Conclusion

Manufacturing today is driven by data, automation, and connectivity. Choosing the best software for manufacturing company is no longer optional. It is essential for efficiency, cost savings, and staying competitive.

Whether it is an ERP for operations, an MES for quality control, or an IoT platform for predictive insights, the right tools will prepare your factory for Industry 4.0. The future is connected and intelligent. Start upgrading now.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox