5 Future Tech Trends Shaping Facilities Inventory Management Software in 2025 and Beyond

Explore 5 future tech trends shaping facilities inventory management software - AI, IoT, cloud, automation, and digital twins.

Managing facility assets isn’t easy. Missing data, surprise breakdowns, and rising maintenance costs are everyday headaches - often made worse by outdated tools and disconnected systems. Compliance becomes a scramble, and decisions are based on guesswork, not facts.

That’s why facilities inventory management software is evolving. Powered by new technologies, it’s moving from basic tracking to intelligent, connected solutions that help organizations stay ahead.

In this article, we’ll look at five tech trends shaping its future in 2025 and beyond, and how they can solve the challenges facility teams face today.

AI and Predictive Analytics in Facilities Management

For years, maintenance has been reactive. A system breaks, technicians scramble, and operations stall. The costs, both in downtime and emergency repairs, are significant. For large facilities, this can mean thousands of dollars per hour in lost productivity.

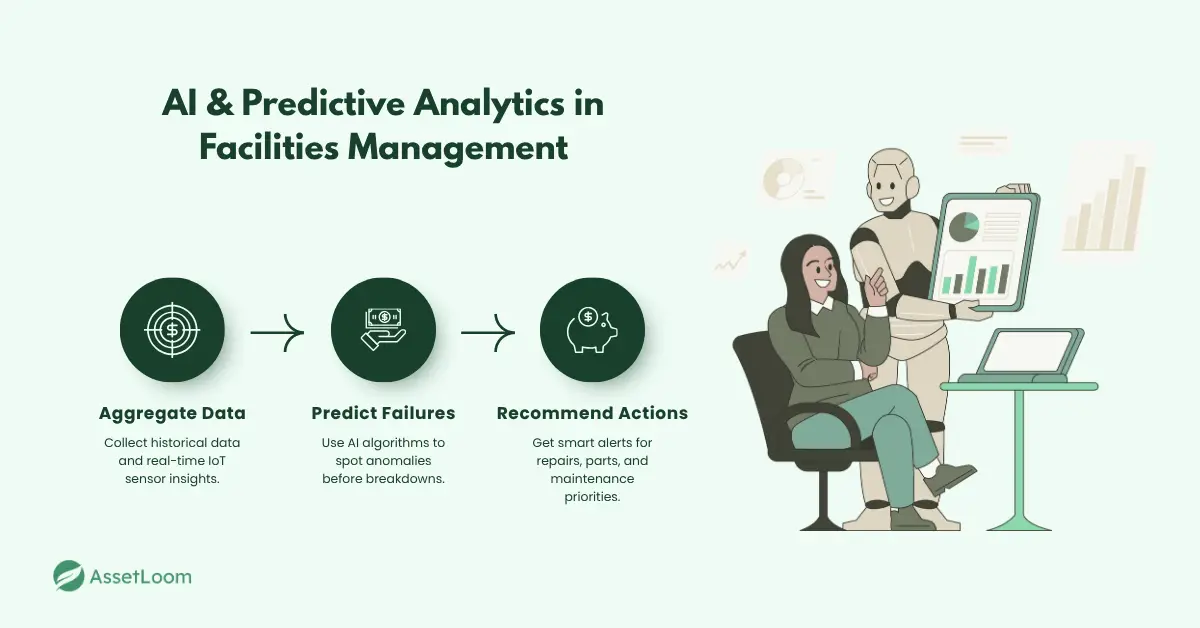

AI-powered predictive analytics changes that by shifting maintenance from reactive to proactive. Here’s how it works:

- Data Aggregation: AI analyzes historical asset performance, usage patterns, and real-time IoT sensor data.

- Failure Prediction: Algorithms detect anomalies like unusual energy spikes or temperature fluctuations long before they become failures.

- Actionable Recommendations: The software does more than show you data. It tells you when to schedule repairs, what parts to order, and how to prioritize maintenance tasks.

Example in practice: A university with multiple campuses uses AI-driven inventory software to monitor HVAC systems. Instead of waiting for units to fail during peak seasons, the system predicts issues based on vibration and energy readings. The result? Maintenance costs drop by 20 percent, and unplanned downtime becomes a thing of the past.

Tip: Start small by applying AI to high-cost or critical assets like HVAC systems. Combine it with IoT sensors for real-time data and make sure historical records are accurate because AI is only as good as the data you feed it.

IoT Integration for Real-Time Asset Tracking

One of the biggest challenges in facility management is not knowing where assets are or how they are performing at any given moment. When equipment goes missing or underperforms without warning, it leads to inefficiencies, delays, and unnecessary costs.

This is where IoT makes a difference. By connecting physical assets to the internet through sensors, facilities inventory management software gains real-time visibility into location, usage, and condition. For example, a temperature sensor on a refrigeration unit can instantly alert teams if the system is running outside optimal conditions, preventing spoilage or damage before it becomes a costly problem.

Example in practice: A large hospital uses IoT-enabled asset tracking software for critical medical equipment like ventilators and infusion pumps. Staff can locate any device in seconds through the software dashboard, eliminating time wasted searching during emergencies and reducing equipment losses.

Read also: Top 10 Medical Equipment Tracking Software in 2025

Tip: Begin with high-value or high-risk assets and add IoT sensors gradually. Prioritize assets that are mobile or critical to operations, and ensure your software platform can integrate seamlessly with IoT systems for real-time updates.

Cloud-First Platforms for Scalable Facility Management

Managing multiple facilities with on-premise systems is expensive, rigid, and often slow to update. IT teams spend countless hours maintaining servers and troubleshooting, while facility managers struggle with limited access when they are off-site.

Cloud-based facilities inventory management software solves these issues by offering real-time access from anywhere and scaling easily as organizations grow. Many cloud-first platforms now integrate software for IT asset management, creating a single source of truth for both physical and IT assets. This unified approach reduces complexity, improves compliance, and simplifies lifecycle tracking.

Example in practice: A multinational corporation shifted from an on-premise system to a cloud-first inventory management platform to manage hundreds of offices worldwide. This change allowed managers to access data from any location, standardize processes across regions, and roll out updates instantly, reducing IT overhead by 35 percent.

Tip: Before migrating to the cloud, evaluate security certifications, compliance standards, and integration options. Look for platforms that support single sign-on (SSO), encryption, and API connectivity to ensure a smooth and secure transition.

Automation and Sustainability Analytics for Smart Decisions

Manual reporting and reactive workflows slow down operations and often result in errors that increase costs. For organizations aiming to meet efficiency and sustainability goals, this is a major obstacle.

Modern facilities inventory management software uses automation to handle repetitive tasks like scheduling preventive maintenance, generating compliance reports, and tracking energy usage. Combined with sustainability analytics, it helps organizations monitor resource consumption, identify inefficiencies, and align with environmental goals.

Example in practice: A large university system implemented automated reporting to track energy consumption across multiple campuses. The software flagged overused equipment and generated actionable insights, reducing electricity costs by 15% in the first year.

Tip: Start by automating high-impact tasks such as preventive maintenance scheduling and compliance documentation. Then expand to energy tracking and sustainability dashboards to align with long-term ESG objectives.

Digital Twins and AR/VR in Facility Maintenance

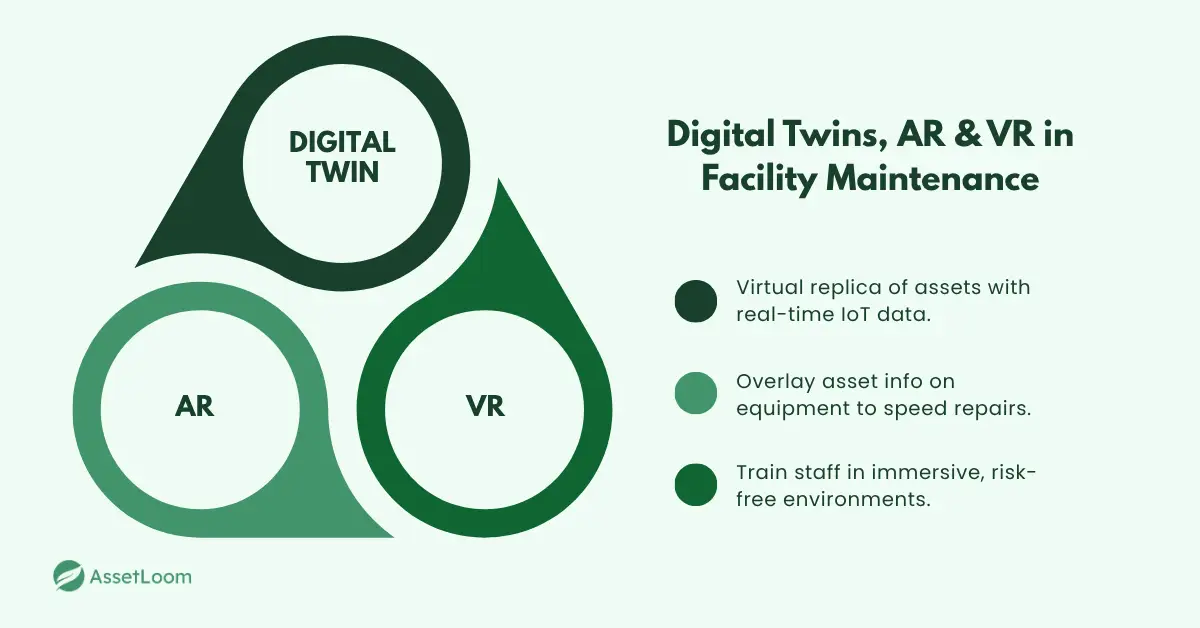

Facility maintenance often relies on limited data and static documentation, making troubleshooting slow and costly. Digital twin technology changes this by creating a virtual model of physical assets and systems. This model reflects real-time data from sensors, allowing teams to simulate scenarios, predict outcomes, and plan interventions before issues escalate.

AR and VR take this a step further. Technicians can use augmented reality glasses to view asset information overlaid on the physical equipment, reducing guesswork and speeding up repairs. Virtual reality environments help train staff without disrupting real operations, improving safety and reducing costs.

Example in practice: A large manufacturing company adopted digital twin technology for its production line equipment. Combined with AR-assisted maintenance, the organization cut diagnostic time by 40% and improved first-time fix rates significantly.

Tip: Begin with critical systems where downtime is costly and training demands are high. Look for software platforms that integrate digital twin models with IoT and AR tools for maximum impact.

Conclusion

Facilities inventory management software is evolving into a powerful, connected platform that uses AI, IoT, cloud technology, automation, and digital twins to deliver smarter operations. These innovations help organizations cut costs, improve uptime, and achieve sustainability goals.

The future of facility management belongs to those who act now. Start identifying which of these technologies can make the biggest impact for your operations and prepare to move from reactive management to proactive, data-driven control.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox