How to Integrate Software for Manufacturing Companies with Existing Systems

Learn how to seamlessly integrate software with existing systems in manufacturing companies for improved efficiency and streamlined operations.

Integrating new software with existing systems can feel like a huge hurdle for many manufacturing companies. Legacy systems often don’t sync well with modern software, creating inefficiencies and disjointed processes. Without proper integration, companies risk facing costly delays, errors, and missed opportunities.

This guide is designed to make the process easier. It walks through each step, helping companies tackle the challenges of integration in a practical and manageable way. With the right approach, manufacturing companies can streamline operations, improve data flow, and boost productivity without the headaches.

Step 1: Assess Your Current Systems and Software

Before diving into integration, it’s crucial to take a close look at the systems already in place. Manufacturing companies often use a mix of legacy systems and modern software, and understanding how they currently work together (or don’t) is the first step in the process.

Start by identifying the key systems in use, like ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), WMS (Warehouse Management Systems), and any other software used for production tracking or inventory management. This will give you a clear picture of what needs to be integrated.

Once you’ve mapped out your systems, assess how they interact with each other. Are they connected in any way? Is data flowing smoothly from one system to the next, or are there bottlenecks that slow down operations? This is also the time to pinpoint any gaps in functionality or areas where new software could bring improvements.

Key Considerations:

- Are your existing systems compatible with potential new software?

- Is there data redundancy, or are certain systems not talking to each other?

- Are there any pain points where systems fail to support business processes efficiently?

By assessing these factors early, manufacturing companies can identify the right software and integration approach that fits their needs, setting a solid foundation for the next steps.

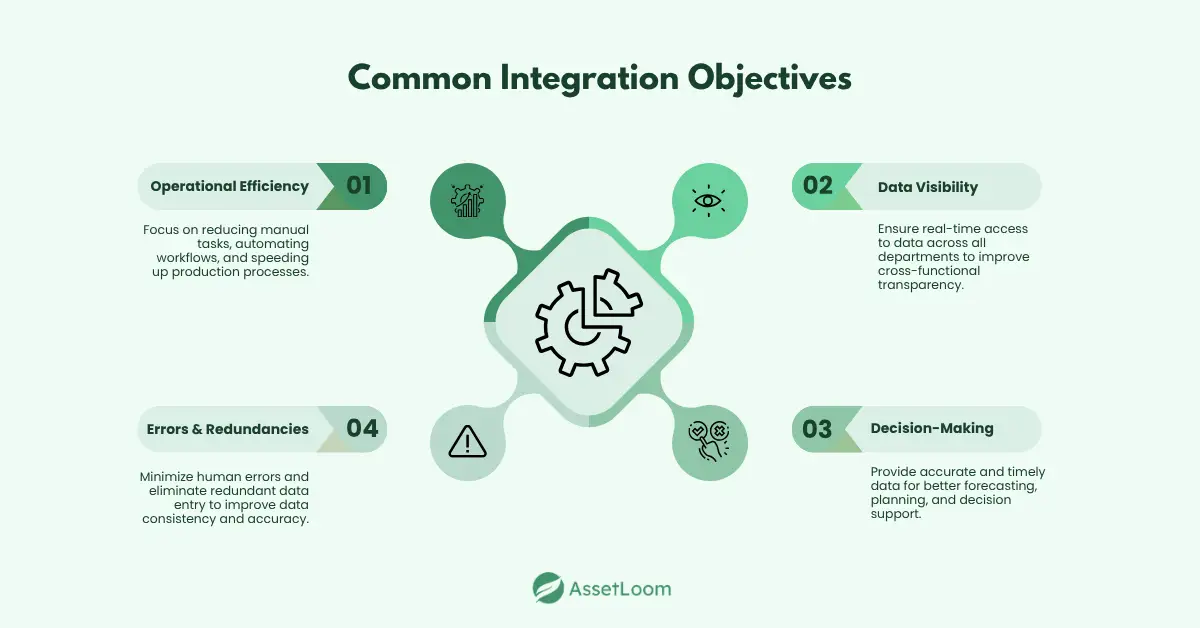

Step 2: Define Your Integration Objectives

Before diving into the technical side of the integration process, it’s essential to define clear objectives. This step ensures that the integration aligns with the company’s broader business goals and helps avoid unnecessary complexity.

Start by asking what the company hopes to achieve with the integration. Some common objectives might include:

- Improving operational efficiency: Reducing manual work, automating processes, and speeding up workflows.

- Enhancing data visibility: Ensuring real-time access to data across departments, such as production, inventory, and sales.

- Optimizing decision-making: Providing managers with more accurate data for better forecasting and planning.

- Reducing errors and redundancies: Minimizing human error and eliminating redundant data entry across different systems.

Once the primary goals are established, prioritize them. For example, if real-time data flow is crucial to managing production and inventory, this should be at the top of the list. By having clear, actionable objectives, the team can focus efforts on the most critical areas and avoid scope creep.

Key Considerations:

- What specific challenges does the company face that integration can solve (e.g., delays in production, poor inventory tracking)?

- How will the integration improve overall business outcomes (e.g., faster decision-making, reduced downtime)?

- What are the measurable results you expect from the integration (e.g., cost savings, improved production capacity)?

Clearly defining these objectives helps keep the integration process focused and ensures it delivers tangible value to the company.

Step 3: Choose the Right Software for Integration

Selecting the right software is crucial for a successful integration. Manufacturing companies should choose software, such as Manufacturing Management Software, that meets their current needs while being compatible with existing systems.

Start by identifying the areas of the business that need improvement, such as real-time production tracking, inventory management, or supply chain optimization. Ensure the software supports APIs or other integration tools that allow smooth communication between old and new systems.

Consider whether the software is cloud-based or on-premise, depending on your company’s needs. Cloud-based solutions offer scalability and flexibility, while on-premise solutions may be preferred for stricter security needs.

Lastly, ensure the software can scale as the company grows and provide adequate support and training for a smooth transition.

Key Considerations:

- Is the software compatible with existing systems?

- Does it meet specific business needs and offer scalability?

- Is it cloud-based or on-premise, and which is better for your company?

By selecting the right software, companies can ensure a seamless integration that supports future growth.

Step 4: Design a Robust Integration Plan

A well-thought-out integration plan is key to ensuring a smooth transition and minimizing disruptions. Start by creating a clear timeline for the integration process, breaking it into manageable phases. This helps ensure the project stays on track and deadlines are met.

Assign specific roles and responsibilities to the team members involved in the integration. This could include IT staff for technical tasks, business leaders for process alignment, and external consultants if necessary. Everyone should know their responsibilities and the expected outcomes.

It’s also important to plan for potential downtime. Integration may require temporary system shutdowns, so make sure to schedule these during off-peak hours to minimize disruption to production.

Key Considerations:

- What’s the timeline for the integration, and what milestones should be hit along the way?

- Who is responsible for each part of the integration process?

- How will downtime be managed to avoid production delays?

A clear and detailed plan sets the foundation for a successful integration, ensuring all parties are aligned and prepared for any challenges that may arise.

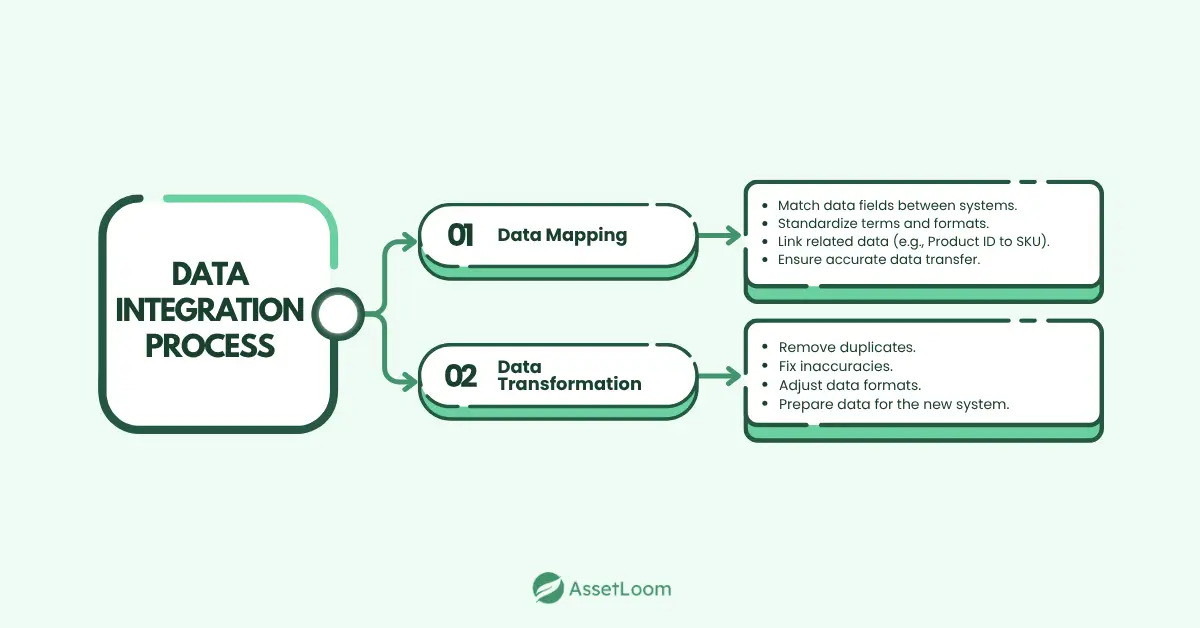

Step 5: Implement Data Mapping and Data Transformation

Once the integration plan is in place, it’s time to focus on data mapping and data transformation. This step ensures that data from existing systems can be transferred and understood by the new software.

Data mapping involves aligning fields in your old systems (e.g., inventory, production data) with those in the new software. This ensures consistency and accuracy in the data being transferred. For example, if your legacy system uses different terminology or formats for inventory tracking, these discrepancies need to be addressed.

Data transformation refers to the process of cleaning and converting data into a usable format for the new software. This may include eliminating duplicates, correcting errors, and ensuring data integrity.

Taking the time to map and transform data carefully helps prevent errors and ensures smooth data flow once the integration is complete.

Key Considerations:

- How will data be mapped between systems to avoid discrepancies?

- Are there any data quality issues (duplicates, errors) that need to be addressed?

- What tools or methods will be used for transforming data to ensure compatibility?

Effective data mapping and transformation are crucial to prevent costly errors down the line and ensure that all systems work seamlessly together.

Step 6: Test the Integration Thoroughly

Once the software is integrated, thorough testing is essential to ensure everything is functioning as expected. Testing should include end-to-end testing, where you simulate real-world scenarios to check how data flows between systems and whether all processes work seamlessly.

In addition to functional testing, it’s important to run user acceptance testing (UAT). This involves having end-users, such as production staff or inventory managers, test the system to ensure it meets their needs and is user-friendly.

Also, conduct load testing to ensure the new system can handle the volume of transactions and data typical for your operations without slowing down or crashing.

Key Considerations:

- Are all systems interacting as expected, with data flowing correctly between them?

- Are end-users able to perform their tasks efficiently in the new system?

- Does the system perform well under typical operational loads?

Testing ensures that any issues are identified and resolved before the system goes live, preventing disruptions once it’s fully implemented.

Step 7: Train Employees and Manage Change

Effective training and change management are essential for a successful software integration. Employees need to understand how to use the new software and adapt to the changes in workflow that come with it.

Start by offering comprehensive training for all relevant staff, such as production teams, inventory managers, and IT personnel. Training should cover everything from basic software use to troubleshooting common issues. It’s also helpful to provide ongoing support through resources like user manuals or a dedicated helpdesk.

Managing change within the organization is equally important. Employees may resist new systems, especially if they’re used to legacy processes. Address this by clearly communicating the benefits of the new software, involving key stakeholders early on, and offering support throughout the transition.

Key Considerations:

- What training resources are needed for employees to become proficient with the new system?

- How can change management be handled to minimize resistance?

- Who will provide support to users post-integration?

With the right training and support, employees will be able to use the new software effectively, ensuring that the integration leads to improved productivity and a smoother transition.

Step 8: Monitor and Optimize the Integration

After the integration is live, continuous monitoring is essential to ensure everything runs smoothly. Track key performance indicators (KPIs) like production efficiency, inventory accuracy, and downtime to assess the success of the integration.

User feedback is also crucial at this stage. Regularly check in with employees to identify any issues or areas for improvement. Over time, optimize the system through software updates, workflow adjustments, and fine-tuning data flows to enhance performance.

Key Considerations:

- Which KPIs will measure integration success (e.g., operational efficiency, uptime)?

- How will user feedback be used to make improvements?

- What ongoing maintenance and support will be needed?

By monitoring performance and staying open to adjustments, companies can ensure the integration remains efficient and scalable.

Conclusion

Integrating new software with existing systems is a crucial step for manufacturing companies looking to improve efficiency and productivity. By following a structured approach - assessing systems, defining goals, choosing the right software, and continuously optimizing - the integration process becomes smoother and more effective.

A successful integration lays the foundation for better decision-making, reduced errors, and future growth. With the right tools and a clear plan, manufacturing companies can streamline operations and stay competitive in an ever-evolving market.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox