How to Use Dashboards to Improve Inventory Accuracy Over Time

Improving inventory accuracy over time with dashboards. Discover practical tips for setup, real-time data tracking, and minimizing errors to streamline inventory management.

Inventory management can feel like a never-ending puzzle. If your inventory is off by even a little, it can lead to bigger issues like stockouts, overstocking, or missed sales. For many businesses, these small inaccuracies add up over time, resulting in unnecessary costs and missed opportunities.

That’s where dashboards come in. By offering real-time visibility into your inventory data, dashboards help you keep everything on track. They simplify the process of monitoring stock levels, tracking trends, and identifying potential issues before they snowball into bigger problems.

In this blog, we’ll walk you through how dashboards can improve inventory accuracy over time. You’ll learn about the common challenges businesses face when managing inventory, how dashboards address those issues, and some practical tips for setting up your own dashboard to streamline operations. Whether you're a supply chain manager, IT professional, or small business owner, these insights will help you make more informed, data-driven decisions to keep your inventory running smoothly.

Common Challenges of Inventory Accuracy

Inventory management can quickly become a headache when accuracy falters. Even small discrepancies in inventory data can lead to costly mistakes, delays, and inefficiencies. These challenges are all too common, and they’re often intertwined, making the task of managing inventory even more complicated. Let’s dive into the top challenges that affect inventory accuracy:

1. Human Error in Counting and Recording

Manual inventory processes are a common source of errors. When your team manually counts stock or enters data by hand, mistakes are bound to happen. A miscount or a wrong entry might seem small, but it can quickly throw off your entire inventory system. This leads to stockouts, overstocking, or ordering products that are no longer needed. Even the best-trained staff can make these types of mistakes, especially if they’re dealing with large amounts of inventory.

Example: “If your team counts items wrong or enters incorrect numbers into the system, you might think you have plenty of stock when, in fact, you're running low.”

Over time, these errors add up, affecting everything from customer satisfaction to order fulfillment, making it difficult to manage your stock effectively.

=> Eliminate Manual Errors with Software Asset Management Automation

2. Lack of Real-Time Data

Inventory isn’t static; it changes constantly. Without real-time updates on stock levels, it’s hard to make decisions based on accurate information. If your inventory data is only updated periodically (once a day, week, or even month), you might not know that a product has sold out or that you have more stock than needed until it's too late. This delay can cause you to miss out on sales opportunities, overstock items, or let problems like stockouts linger longer than they should.

Example: “If your inventory system only updates once a day, you might not know that a popular product has sold out in the morning until the next day. This means you’re missing out on potential sales and frustrating customers who can’t get the products they need.”

3. System Integration Issues

Many businesses use different software systems like ERP, CRM, or point of sale software to track sales, orders, and inventory levels. However, if these systems don’t integrate well, it leads to data mismatches and confusion.

For example, if your sales system is separate from your inventory management system, it’s easy for data to get out of sync. This can cause you to believe you have more stock than you actually do or miss the fact that a product has sold out until it’s too late.

4. Theft, Damage, or Misplacement

Even the best systems can’t account for physical damage, theft, or simple misplacement of products. Items can get lost or stolen without anyone noticing right away, and when inventory records aren’t updated quickly, it’s easy for these losses to go undetected. This leads to discrepancies in your inventory count, which can result in stockouts, overstocking, or incorrect order fulfillment.

Theft or loss of inventory is a common problem, but if you're not tracking your stock properly, these issues will compound over time, creating bigger gaps in your inventory data.

5. Lack of Visibility and Tracking

In large or distributed inventories, it can be difficult to know exactly where assets are or what condition they’re in at any given time. This lack of visibility makes it harder to track product movement and can lead to confusion about stock levels. Without a clear picture of where your inventory is at all times whether it’s in the warehouse, on the shelf, or being shipped—you risk losing control over your stock, which can lead to inaccuracies and delays in fulfillment.

Example: “If your inventory management system doesn’t track items in real time across multiple locations, you could end up with duplicate orders or products stuck in the wrong place, resulting in a poor customer experience.”

Without proper Asset Tracking Software, it’s easy for products to go missing or be misplaced, making inventory management that much more difficult.

These challenges don’t happen in isolation. They often feed into one another. For example, a lack of real-time data can lead to more human errors, and relying on manual processes makes it more difficult to detect theft or damage. In the next section, we’ll explore how dashboards can help address these problems and improve your inventory accuracy over time.

How Dashboards Improve Inventory Accuracy Over Time

Dashboards play a crucial role in modernizing inventory management. They replace outdated manual processes and offer a clear, real-time view of inventory data. By consolidating key metrics into one easy to understand interface, dashboards help improve decision-making, reduce errors, and increase operational efficiency. Here’s how they help improve inventory accuracy over time:

1. Real-Time Data and Instant Visibility

Dashboards provide real-time updates, ensuring you always have the most current information available. With live data, you can track stock levels, monitor sales, and see product movements as they happen. This immediate visibility makes it easier to spot issues before they become major problems, such as stockouts or overstocking, giving you the time to take action and make decisions based on accurate, up-to-date information.

This instant visibility is essential for businesses that need to stay agile and respond quickly to changes in demand or supply.

2. Minimizing Human Error and Data Discrepancies

One of the biggest challenges in inventory management is human error. Manual processes, like hand-counting inventory or entering data by hand, are prone to mistakes that can throw off your entire system. Dashboards help reduce these errors by automating the data collection and updating process. When integrated with other systems (like your sales or order management systems), dashboards pull in accurate data automatically, eliminating the need for manual updates.

This automation reduces the chance of discrepancies and ensures that everyone in your organization is working with the same accurate data, reducing confusion between teams and minimizing the risk of mistakes.

3. Proactive Inventory Management with Alerts

Dashboards aren’t just about presenting data, they also help you manage your inventory proactively. With customizable alerts, you can set up notifications for low stock levels, excess inventory, or other inventory issues. These alerts help you stay ahead of potential problems, ensuring that you're never caught off guard by stockouts or overstocking.

Whether it’s a warning that stock is running low on a popular item or a reminder to order more supplies, these alerts give you the heads-up you need to take action in time to prevent costly mistakes.

4. Data-Driven Insights and Forecasting

Dashboards do more than track current inventory they also help you analyze past performance and trends. By reviewing historical data, you can identify patterns in demand, sales trends, and seasonal fluctuations. This insight allows you to better forecast future inventory needs, helping you avoid both overstocking and stockouts.

For example, if your dashboard shows that certain items sell faster during specific times of the year, you can plan ahead and make smarter purchasing decisions based on these trends. This forecasting ability leads to more accurate inventory planning, improving overall inventory efficiency.

5. Improved Decision-Making with Visual Analytics

Dashboards display data visually, using charts, graphs, and gauges that make it easier to understand inventory trends at a glance. Instead of sifting through complex reports, you can see the health of your inventory in a simple, visual format. This makes it easier to identify areas for improvement, such as slow-moving products, items that need restocking, or potential supply chain issues.

By presenting data in a visual format, dashboards allow managers to quickly identify critical issues and make data-driven decisions that keep inventory running smoothly. This reduces decision-making time and improves overall operational efficiency.

Dashboards provide real-time visibility, automate data updates, and offer proactive management tools like alerts and forecasting. They help eliminate errors, give businesses the tools to make smarter decisions, and improve inventory accuracy over time. With clear, actionable insights at your fingertips, dashboards make inventory management simpler, more accurate, and more efficient.

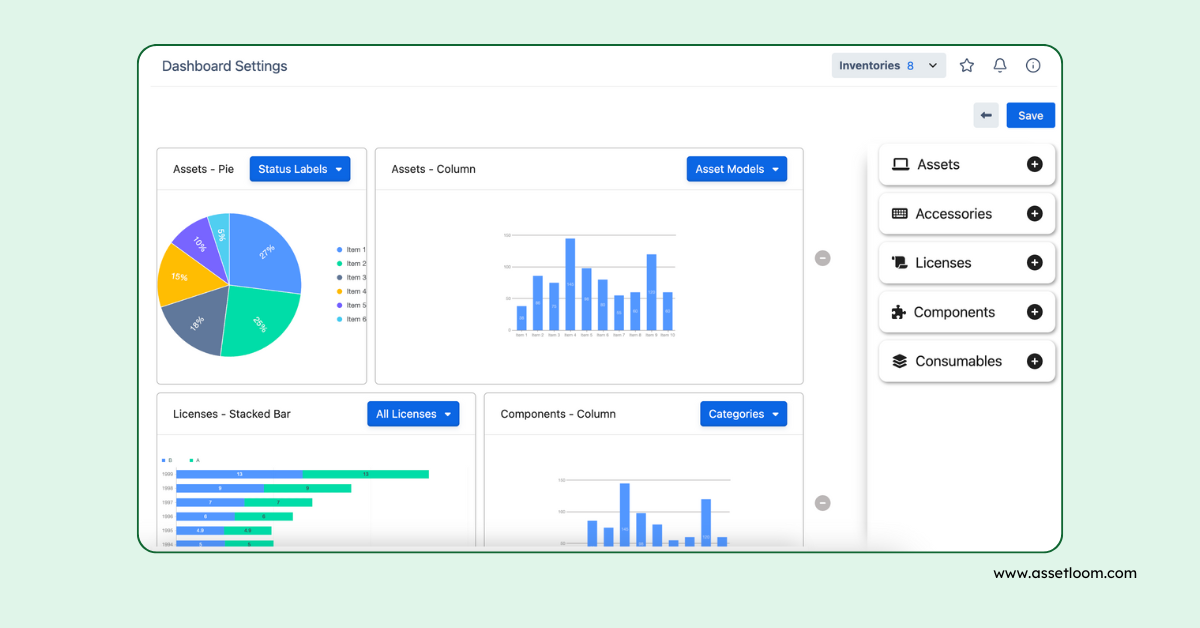

AssetLoom’s Comprehensive Dashboard Features

AssetLoom offers a powerful and customizable dashboard that helps you manage inventory with ease. Here are some key features:

- Real-Time Updates and Customizable Views: Get live data on stock levels and sales, with the ability to tailor your dashboard to show the metrics that matter most.

- Automated Data Syncing: Integrates with your existing systems, ensuring that inventory data is always accurate and up to date.

- Alerts and Notifications: Set up notifications for low stock or discrepancies, allowing you to address issues before they escalate.

- Visual Analytics: Use charts and graphs to quickly assess inventory health, track trends, and make informed decisions.

- Comprehensive Overview: Monitor all key inventory metrics in one place, from stock turnover to sales performance.

AssetLoom helps streamline your inventory management by providing real-time insights, reducing manual errors, and offering proactive alerts for better decision-making.

Practical Tips for Setting Up Inventory Dashboards

Setting up an inventory dashboard might seem like a daunting task, but with the right approach, it can be straightforward and highly beneficial. Here’s a step-by-step guide to help you set up your own dashboard and ensure it’s tailored to your business needs:

1. Identify Key Metrics to Track

Before setting up your dashboard, it’s crucial to determine which inventory metrics are most important to track. Key metrics can include:

- Stock levels: Know how much of each product is on hand.

- Turnover rates: Track how quickly items are selling.

- Stockouts and overstocking: Monitor whether you’re ordering too little or too much.

- Lead times: Measure how long it takes to replenish stock.

Tip: Start by identifying the metrics that directly impact your business goals. For example, if you struggle with out-of-stock issues, tracking low-stock alerts might be a priority.

2. Choose the Right Dashboard Tool

Not all dashboard tools are created equal, so selecting the right one is key to ensuring you get the insights you need. Look for a tool that integrates with your existing systems (like sales platforms, POS systems, or inventory management software). This integration ensures that data is pulled in automatically and updated in real time.

Tip: Consider tools like AssetLoom, which offers a customizable dashboard that integrates with existing systems, making setup easy and effective.

3. Customize Your Dashboard for Clarity

A cluttered dashboard can be overwhelming and hard to navigate. To avoid this, focus on presenting only the most important data that directly impacts your inventory management. Use graphs, charts, and gauges to display information in a visual format that’s easy to understand at a glance.

Tip: Organize your dashboard into clear sections, such as stock levels, alerts, and performance trends, to make the data easier to digest.

4. Set Up Alerts and Automated Reporting

Alerts are one of the most powerful features of an inventory dashboard. Set up notifications for things like low stock levels, excess inventory, or discrepancies. Automated reports can also save you time by sending regular updates on your inventory status, so you don’t have to manually check each time.

Tip: Customize your alerts to match your inventory needs. For example, if you deal with seasonal products, set up alerts for products that need to be reordered in advance.

5. Train Your Team and Foster a Data-Driven Culture

Once your dashboard is set up, make sure your team knows how to use it. Provide training on how to interpret the data and take action based on the insights provided. The more comfortable your team is with using the dashboard, the more effective it will be.

Tip: Make dashboard usage a part of your daily operations. Encourage team members to check the dashboard regularly to stay on top of inventory issues.

Setting up an inventory dashboard can significantly improve the way you manage your stock. By tracking the right metrics, selecting the right tool, customizing for clarity, and setting up alerts, you’ll have a system that helps you stay ahead of inventory issues. With proper training and a focus on using the dashboard regularly, it will become an essential tool for maintaining inventory accuracy over time.

Conclusion

Accurate inventory management is essential for business success, and dashboards provide an effective way to simplify the process. By offering real-time data, reducing human error, and providing proactive alerts, dashboards help improve inventory accuracy over time.

With the right metrics, tools, and team training, dashboards can transform how you manage your inventory, ensuring you stay on top of stock levels, avoid overstocking and stockouts, and make smarter decisions.

If you’re ready to improve your inventory management, consider using tools like AssetLoom for a customizable, real-time dashboard that integrates with your existing systems.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox