How to Manage End-of-Life Equipment the Smart Way

Learn how to manage end-of-life equipment effectively through planning, secure disposal, and smart lifecycle tracking to keep your business running smoothly.

If you’ve ever had an old computer crash in the middle of an important task, you know how stressful it can be. Outdated equipment doesn’t just slow people down — it causes downtime, data loss, and unexpected costs. Yet, many businesses still hold on to old devices long after they stop being reliable.

Every piece of equipment eventually reaches a point where it’s no longer worth fixing or updating. This stage is called End of Life (EOL). It simply means the manufacturer has stopped making, selling, or supporting that device or software. When that happens, it’s time to think carefully about what to do next.

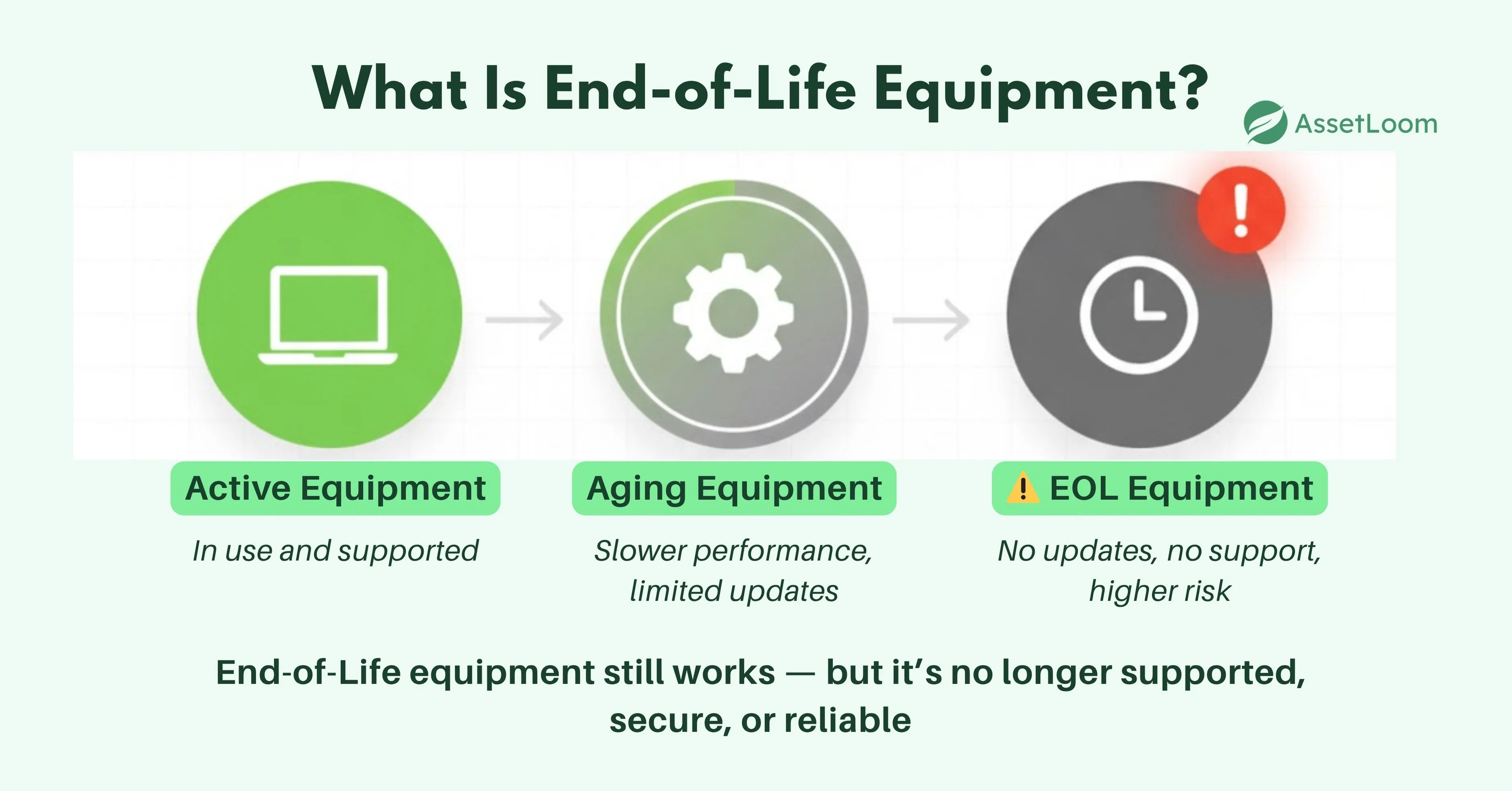

What Is End-of-Life Equipment?

End-of-Life Equipment, or EOL Equipment, simply means that a piece of equipment has reached the end of its usable life from the manufacturer’s point of view. This doesn’t mean it suddenly stops working, but it does mean that the company that made it no longer sells it, supports it, or provides updates.

For example, think about an old laptop that still turns on but can’t handle the latest software updates. Or a server that’s been running for years but no longer gets security patches. These are signs that the equipment has reached its end of life.

In most organizations, every IT asset goes through a process known as the IT asset lifecycle, which includes five main stages:

- Planning and Procurement – deciding what equipment is needed and purchasing it.

- Deployment – setting it up and making it available for use.

- Maintenance – keeping it updated, repaired, and performing well.

- End of Life (EOL) – when the manufacturer stops making, supporting, or updating it.

- Disposal or Retirement – securely removing data and reusing, recycling, or discarding the asset responsibly.

When equipment reaches the EOL stage, it’s a sign to prepare for the final step — retirement. Managing this part of the lifecycle properly helps prevent downtime, protect data, and plan future purchases more efficiently.

What’s the Difference Between EOL, EOD, and EOSL?

When you manage IT equipment, it’s important to understand that hardware and software don’t stay current forever. Over time, every device or system moves through several stages that affect how long it can be safely and effectively used. Three of the most important stages to know are End of Life (EOL), End of Development (EOD), and End of Service Life (EOSL).

Each stage tells you something different about the level of support and updates your equipment will receive. Here’s how they differ:

End of Life (EOL)

This is the point when the manufacturer stops producing, selling, or officially supporting a product. You may still be able to use it for a while, and limited support could be available, but no new units can be purchased directly from the manufacturer. At this stage, businesses should start planning to replace or upgrade the asset before support fully ends.

Example: A laptop model that’s no longer sold in stores or listed on the manufacturer’s website has reached EOL.

End of Development (EOD)

At this stage, the manufacturer stops releasing updates, fixes, or new features for the product. The equipment or software can still be used, but it won’t improve or keep up with modern standards. This often leads to compatibility or performance issues over time.

Example: A network switch that still works but no longer receives firmware or feature updates has reached EOD.

End of Service Life (EOSL)

This is the final stage in the equipment lifecycle. The manufacturer completely stops offering any kind of support, including maintenance, repairs, spare parts, and security updates. Once a product reaches EOSL, users are on their own. They can either rely on third-party maintenance or retire the asset altogether.

Example: A server that no longer has available replacement parts or vendor support has reached EOSL.

These stages mark key turning points in the hardware and software lifecycle. Each one means a gradual loss of updates, repairs, and technical support. Knowing where your equipment stands helps you plan upgrades early and avoid disruptions or security risks that come from running outdated systems.

Here’s a quick summary for easy comparison:

| Lifecycle Stage | EOL | EOD | EOSL |

|---|---|---|---|

| What it means | Manufacturer stops selling, producing, and supporting the hardware. | No new updates, fixes, or features are released. | Manufacturer ends all support, including maintenance and repairs. |

| Availability | Product may still work but can’t be bought new. | Product still runs but receives no improvements. | Product may still work but has no support or parts available. |

| Implications for users | No new units available; limited support remains. | Fewer improvements; compatibility may decline. | No repairs or troubleshooting support; must plan for replacement. |

| Support | Partial or ending support. | No new updates, only critical patches. | No official support; third-party help only. |

| Impact on business | Plan maintenance or upgrades soon. | Monitor for performance and compatibility issues. | Replace equipment to avoid failures or risks. |

Understanding these stages helps you make better decisions about when to upgrade, repair, or retire your assets — before they start affecting productivity or security.

Why Is It Important to Manage End-of-Life Equipment?

Many businesses keep using old equipment simply because it still works. But just because a device turns on doesn’t mean it’s safe, efficient, or cost-effective to keep around. Ignoring end-of-life equipment can lead to hidden problems that often cost more than replacing it.

Here are the main reasons why managing EOL equipment matters:

1. Protects Your Data and Network Security

Outdated hardware and software no longer receive security updates or patches. That means any new vulnerability is left open for hackers to exploit. Even one unpatched computer or router can put your entire network at risk. By retiring or upgrading end-of-life assets on time, you reduce the chance of data breaches or malware attacks.

2. Ensures Compliance with Regulations

Many industries require organizations to properly handle or destroy equipment that stores sensitive data. If old devices aren’t wiped or disposed of correctly, you could face compliance issues or even legal penalties. Managing your EOL assets helps ensure that all data is securely erased and that disposal meets privacy and environmental standards.

3. Saves Money in the Long Run

It may seem cheaper to keep using old hardware, but the opposite is often true. Maintenance costs rise as equipment ages, parts become harder to find, and downtime becomes more frequent. Planning for EOL means budgeting for replacements early, avoiding surprise expenses, and keeping your systems running efficiently.

4. Improves Performance and Productivity

Old devices slow people down. When computers take minutes to start or printers constantly jam, productivity drops. Replacing end-of-life equipment helps your team work faster and with fewer interruptions.

5. Supports Environmental Responsibility

Properly managing EOL equipment means you’re not just throwing it away. Many components can be recycled, reused, or donated. Responsible disposal reduces electronic waste and supports sustainability goals.

Managing end-of-life equipment isn’t just about avoiding problems — it’s about staying prepared. By keeping track of when your assets are nearing the end of their lifecycle, you can plan replacements in advance, protect sensitive data, and make smarter decisions for your business.

How Can You Tell When Equipment Is Nearing the End of Its Life?

Knowing when your equipment is getting close to the end of its life helps you avoid downtime, plan replacements, and prevent security issues. You can often tell through official notices from the manufacturer or by watching for changes in performance and reliability.

Here’s what to look out for:

1. Official Notices and Dates

Manufacturers usually announce when a product is nearing its end of life. These updates are important because they tell you how long your equipment will continue to receive support and maintenance.

- End of Life (EOL): The manufacturer has stopped producing and selling the model.

- End of Service Life (EOSL): The manufacturer no longer provides technical support, maintenance, or repairs for the equipment. This usually happens after the EOL date, when spare parts and vendor assistance are no longer available.

How to find these dates: Check the manufacturer’s website, product documentation, or direct emails from the vendor. Some third-party maintenance providers also publish databases that list official EOL and EOSL dates for common hardware models.

2. Performance and Operational Signs

Even without official notices, your equipment may show signs that it’s reaching the end of its life.

- Increased downtime: Devices fail more often, causing interruptions in daily work.

- Higher maintenance costs: Repairs and replacements become more frequent and expensive.

- Slower performance: The equipment struggles to keep up with newer software or heavier workloads.

- Frequent breakdowns: You spend more time fixing problems than using the device productively.

3. Security and Support Risks

As equipment gets older, it becomes harder to keep it safe and compatible with current systems.

- Lack of updates: The manufacturer stops releasing security patches or firmware updates.

- Security vulnerabilities: Outdated devices are easier targets for cyberattacks.

- Incompatibility issues: Older hardware may not work well with newer software, networks, or operating systems.

When you start noticing several of these signs, it’s a good idea to review your asset list and plan replacements. Staying proactive helps you avoid sudden failures, protect data, and keep your systems running smoothly.

How Can You Manage End-of-Life Equipment?

Managing end-of-life (EOL) equipment isn’t just about throwing old devices away — it’s about making smart, responsible decisions at the right time. In real life, that means staying organized, protecting data, and planning replacements before equipment fails.

Here’s how to manage EOL equipment in a practical, hands-on way:

1. Start with a Full Equipment Audit

Begin by knowing what you have. Walk through your office, data center, or warehouse and list every piece of equipment — laptops, servers, monitors, routers, even old backup drives sitting in drawers. Record key details like:

- Purchase date and warranty

- Model and serial number

- User or department assigned

- Current condition

- EOL or EOSL dates

This helps you see which assets are still in good shape and which are nearing the end.

2. Prioritize What to Replace First

Once you have your list, focus on what’s critical. For example:

- A file server that stores company data should come before an old printer in the break room.

- A network firewall nearing EOL poses a bigger security risk than a projector in a meeting room.

Think in terms of impact and risk — what equipment would hurt operations the most if it failed tomorrow?

3. Budget for Replacements Early

Don’t wait for a full breakdown to start shopping for replacements. Spread out your upgrade costs over the year. For example:

- Replace 25% of your laptops every year instead of all at once.

- Set aside part of your IT budget for emergency replacements.

Planning like this avoids sudden expenses and keeps your systems running smoothly.

4. Extend the Life of What You Can

Not everything needs to be replaced right away.

- Perform regular cleaning and maintenance to reduce wear.

- Upgrade memory or storage in older computers if they’re still reliable.

- Use third-party maintenance (TPM) providers for spare parts and extended support after the manufacturer ends it.

This helps you get the most value from your investment without compromising performance.

5. Protect Data Before You Dispose of Anything

Before retiring any device, back up or migrate all important data. Then, make sure it’s securely erased so nothing can be recovered later. If your equipment contains sensitive information — like employee records or client data — use certified data destruction tools or services.

A company retiring old laptops should never just “delete files.” They should wipe or destroy drives following proper data security standards.

6. Dispose Responsibly

Never throw old IT equipment in the trash.

- Recycle through a certified e-waste partner who can safely handle electronic components.

- Donate or resell working devices to schools, charities, or startups.

- Repurpose usable parts like RAM or drives for less critical systems.

Always ask your disposal partner for a certificate of data destruction and recycling for your records.

7. Keep a Record of the Whole Process

Document every step — when an asset was retired, who handled it, how data was destroyed, and where it went next. This not only keeps you compliant with data protection laws but also proves accountability during audits.

8. Train Your Team and Communicate

Make sure your employees know what to do when they receive EOL notices or start noticing slow performance. Encourage them to report failing devices early — before they break completely.

9. Make It a Continuous Process

Managing EOL equipment isn’t a one-time task — it’s ongoing. Regularly update your inventory, review EOL timelines, and schedule periodic checks. Treat it like any other essential part of your IT maintenance routine.

How Can AssetLoom Help with End-of-Life Equipment?

Managing end-of-life (EOL) equipment becomes much easier when everything is organized, tracked, and automated in one place. AssetLoom helps you stay in control of your hardware lifecycle by giving you the tools to plan ahead, reduce risk, and keep your assets up to date.

Centralized asset tracking

- Store all asset details — purchase date, serial number, warranty, and EOL or EOSL dates — in one platform.

- View your entire inventory at a glance to see which assets are active, aging, or ready for replacement.

Use smart tags for easy identification

- Label equipment with QR codes or barcodes for quick scanning and instant access to details.

- Simplify audits and updates by tagging assets across different locations or departments.

Monitor asset depreciation

- Track how each asset loses value over time.

- Use depreciation data to plan budgets, calculate replacement costs, and make informed financial decisions.

Track the entire hardware lifecycle

- Follow each asset from purchase and deployment to maintenance, end of life, and disposal.

- Keep full visibility of every stage to avoid forgotten or unaccounted assets.

Automate hardware refresh workflows

- Set automated reminders for warranty expiry, EOL, or EOSL dates.

- Notify the right people — IT managers, procurement, or department heads — when an asset needs to be reviewed or replaced.

Allocate assets to the right person in charge

- Assign each asset to a responsible user or department for accountability.

- Keep track of who owns or uses each piece of equipment to make returns, maintenance, or replacements easier.

Maintain compliance and records

- Store disposal certificates, data destruction reports, and audit logs.

- Ensure every asset retirement is documented and meets data protection or environmental standards.

By combining all these features in one system, AssetLoom helps you manage end-of-life equipment in a structured, proactive way — saving time, reducing errors, and keeping your IT environment secure and well-organized.

What’s the Best Way to Move Forward?

Dealing with end-of-life (EOL) equipment doesn’t have to be stressful. The key is to stay one step ahead — know what you have, know when it’s reaching the end, and have a plan ready before problems start.

Start small. Keep an updated list of your assets and review it regularly. Watch for EOL or EOSL notices from manufacturers and pay attention to signs like slow performance or rising maintenance costs. When the time comes, handle disposal responsibly — back up your data, wipe it securely, and recycle or repurpose what you can.

Building this process into your regular operations makes a big difference. It reduces downtime, protects sensitive information, and helps your business use technology more efficiently.

Managing end-of-life equipment isn’t about replacing everything at once — it’s about making thoughtful, timely decisions that keep your systems running smoothly and your data safe. When you plan ahead and stay organized, you stay in control.

Related Blogs:

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.