What Is Manufacturing Management Software and Why You Need It

Discover what manufacturing management software is, how it works, and why it’s essential for streamlining operations and improving efficiency.

Operating a manufacturing company today is quite the feat; increasing competition, coupled with the recent experience of supply chain-related issues, shortage of staff, and increased prices (a perfect storm of problems), does not make it easier. If you are running your company with a string of spreadsheets and/or piecing together systems, you are likely making matters worse, which only adds stress to your daily work life.

Manufacturing management software is not the magic bullet of manufacturing management, but is a helpful, practical tool to create and deliver value in order to overcome the chaos of juggling many tasks. In this article, we will walk through what manufacturing management software does, how it will fit into your to-do list and operations, and provide value for you to consider to take a deep breath when looking for ways to maintain or improve your manufacturing business.

What Is Manufacturing Management Software?

Manufacturing management software aids you in organizing your open and closed production processes, materials tracking, and timeline compliance in a systematic and temporary manner. Instead of managing spreadsheets, sticky notes, and disconnected tools, it supplies one system to manage all of these responsibilities.

In some cases, manufacturing management software can also tie into other systems, like IT Asset Management (ITAM), to further support manufacturers by tracking their infrastructure in both digital and physical forms. This continuity assures that their production equipment and software licenses are all identified and maintained properly.

Its Role in the Manufacturing Ecosystem

Consider it as the brain of your factory. From production to inventory to purchasing to quality, it creates a common language to improve a manufacturing environment where everyone moves in the same direction. Nobody lives in their silo; there is no guesswork. When things change (and they always do), the system allows you to respond quicker.

If there is a low inventory of raw materials, procurement is notified. If a job is falling behind, production is aware and can adjust. It keeps things moving and provides visibility of the floor, not just the paper trail.

Common Modules (What They Usually Include)

Most manufacturing management software comes with a few core features that help you run the day-to-day:

- Production planning & scheduling – So you know what’s getting made, when, and with what.

- Inventory Tracking – Know what’s in stock, what’s on the way, and what you’re running out of.

- Work order management – Easily assign tasks and keep track of what’s done and what’s still pending.

- Shop floor monitoring – See real-time updates from machines or operators.

- Quality checks – Record inspections, flag issues, and keep everything documented for audits or standards.

- Reporting – Track performance, spot problems, and make better decisions with live data.

These features help you stay in control, even when things get chaotic.

Who Uses It?

- Production managers use it to manage the workflow and easily recognize problem areas before they become major bottlenecks.

- Inventory and procurement personnel use it to make sure they won’t run out of materials in production or have a ton of inventory that won't be used.

- Owners or plant managers use it as a way to see the activity going on in the facility from a bird’s eye view of what's working, what's not working, and where they need to focus their attention.

- Project managers use it to coordinate timelines and resources across multiple production lines or client orders.

It’s useful whether you’re managing 10 people or 100.

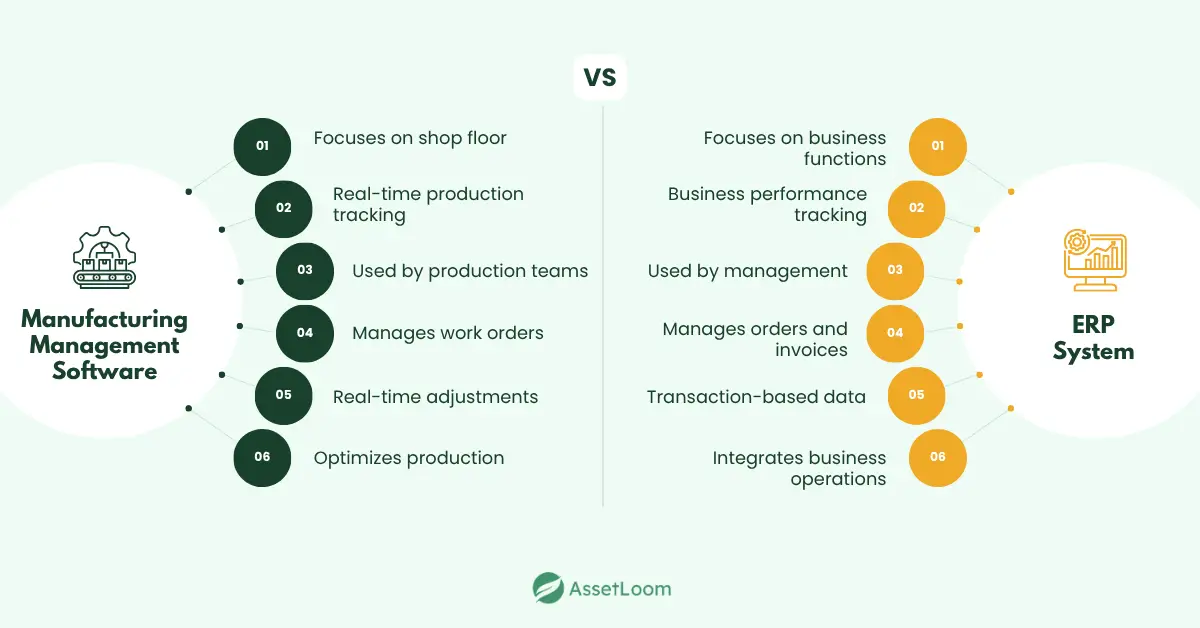

How It's Different from an ERP

You might already have an ERP system that tracks orders, invoices, or customer info. Many manufacturing businesses use enterprise resource planning (ERP) platforms to track orders, invoices, and customer information. Some ERPs even have basic production features. But here’s the difference:

ERP is well-suited for managing the business side of things, including accounting, HR, and sales.

Manufacturing management software is built for the shop floor. It’s more operational than transactional, with real-time tools that production teams actually use day to day.

Real-World Example:

Your ERP might tell you an order is “in progress.”

But your manufacturing software will say, “It’s 60% complete, it’s on Line 2, there’s a holdup because it ran shorter than normal, and unless I make an adjustment, it will miss the delivery window.”

That kind of visibility is what makes it so valuable both for large manufacturers and for any team that needs tighter control over production.

Core Functions and Capabilities

Manufacturing management software does much more than show data. It’s about making your work life easier and supporting your team’s ability to maintain the production and manufacturing processes. Let’s run through some of the core things it does, and how it looks in practice on the floor:

1. Production Planning and Scheduling

No more whiteboards or last-minute guesswork. The software helps you build a plan for what’s getting made, when, and in what order, often including material requirements planning (MRP) features to align materials with production schedules. It keeps production balanced and avoids overloading one area while another sits idle.

Real-world value: You can quickly shift the schedule if a machine goes down or a rush order comes in, without throwing the whole week off.

2. Inventory and Materials Management

It monitors raw materials, components, and finished products all the time and keeps inventory accurate throughout the production process. Some systems also keep track of bills of materials (BOM), where an item sold to a customer has every requisite part to complete it. Some just keep track of inventory, but you could set up minimums, automate reorder notifications, and even tie inventory to specific jobs.

Real-world value: We avoid the mess of you starting a job, and halfway through, you realize you’re missing an essential part. You will avoid delays and rework – as a result, saving considerable money!

Read also: What is Inventory Management? Definition, Scopes, Methods

3. Work Order Management

Rather than printing out instructions or texting members with updates, you can create digital work orders with all the details, what needs to be done, who is doing it, and what materials to use. Workers can complete the task or report if problems are encountered through the system.

Real-world value: No more chasing people down for updates. You get clear visibility into what’s in progress and what’s holding things up.

4. Shop Floor Monitoring

You can track what’s happening on the floor as it happens - job status, machine performance, labor hours. Some systems even connect directly to machines (IoT) to collect real-time data.

Real-world value: If a line is falling behind or idle, you know immediately, not three days later when the order’s already late.

5. Quality Control

You can log inspections, flag defects, and document corrective actions in one place, which helps with audits, customer standards, internal improvement, and ultimately boosts customer satisfaction.

Real-world value: No more missing paper checklists or undocumented issues. You have a record of every quality check and outcome.

6. Reporting and Dashboards

You get access to reports and KPIs like:

- Customer orders by status

- Order completion rates

- Downtime and scrap rates

- Machine utilization

- Inventory turnover

Dashboards help you spot patterns and make informed decisions without digging through spreadsheets.

Dashboards help you see trends, which leads to insights, rather than simply pulling data out of spreadsheets.

Real-world value: Instead of running blind with limited data, you will have some insights into what you need to address/repeat/sustain to eliminate bottlenecks, cut waste, and improve delivery performance.

None of these functions is bad, but when they are connected in only one system, the operation is a lot cleaner and a lot more responsive.

Why Manufacturers Need It

Manufacturing management is not about abstractions, but about moving quickly when the pressure is on. It may be a small shop or a large-scale manufacturing business, but visibility and control are what matter. These are problems manufacturers face on a day-to-day basis, and this is how software can help manufacturers solve immediate, real, concrete problems.

1. Too Many Moving Parts, Not Enough Visibility

The reality: Your production plan is in Excel. Inventory is tracked by hand. Job updates come from someone yelling across the shop floor. That might have worked when things were smaller, but now it’s chaos.

How software helps: It brings all that information into one place. The production plan, material status, and job progress are live and visible to everyone.

If you’re not using software yet: Start by mapping out all the sources of data you currently rely on - whiteboards, spreadsheets, paper orders - and ask: Who sees this? Who doesn’t? That’ll show you your biggest blind spots.

2. Production Delays and Bottlenecks

The reality: You plan for everything to run smoothly, but a late material delivery or machine breakdown throws it all off, and no one sees it coming until it’s too late.

How software helps: It tracks jobs and materials in real time and alerts you when something’s late or stuck. You can reassign work before it causes a domino effect.

Pro tip: Even without software, start logging daily delays: What caused them? How long did they last? After a week, you’ll see patterns you can start addressing.

3. Inventory Guesswork

The reality: A person believes that there are 12 units available, but in fact, only 3 exist. You commence the job regardless, and then have to stop midway through the process. Now the order is late, and your crew is upset.

How software helps: It will automatically update the inventory levels as the materials are received or consumed, giving you visibility in inventory levels in real-time and helping you make decisions to avoid surprises and more expensive.

Quick fix idea: Initiate a Kanban board or card system for the key materials, so teams can visually see inventory levels and needs, even before software is implemented.

4. Inefficient Communication

The reality: Work orders are printed and passed around. Changes happen mid-shift, but the updated info doesn’t reach the person doing the job. Mistakes follow.

How software helps: Instructions and job details are updated digitally, so everyone sees the latest version in real time, no more outdated paperwork.

If you're not digital yet: Try creating a shared binder or whiteboard on the floor for job changes. It’s a temporary step, but it helps reduce the noise.

5. No Time for Improvements

The reality: You spend your day reacting, fixing problems, answering questions, and finding parts. There's no time to look at the bigger picture, let alone optimize.

How software helps: It gives you visibility into your top recurring issues, like repeat delays, scrap, or downtime, so you can actually fix root causes, not just symptoms.

Try this: Pick one problem this week (like rework or machine downtime) and ask “why” five times. You’ll likely discover it’s not a people issue; it’s a process issue.

Manufacturing management software doesn’t just help you “go digital.” It gives you the breathing room and insight to finally get ahead of the daily chaos and start building a more stable, more scalable operation.

Conclusion

Operating a manufacturing facility is not simple. You are continuously juggling machines, people, materials, and timeframes. Sometimes all at the same time. When the tools you are working with don't keep up, the task can become even more complicated.

Manufacturing management software isn't a magic button. But it does provide you with something tangible to grab, dependable schedules, real-time updates, fewer errors, and a lot less guesswork.

It is not to increase technology for tech's sake. It is to make your workday and your teams easier to manage. Less chaos. More control. And time to fix things instead of just making do with whatever happens.

So if you are constantly running spreadsheets, following paperwork trails, or chasing answers down... it may be time to try a system that is actually built the way your shop works.

Frequently Asked Questions

1. What exactly is manufacturing management software?

Manufacturing management software helps you keep everything running smoothly by organizing tasks like scheduling, tracking inventory, and managing work orders. It gives you a clear, real-time view of what's happening on the floor, so you can stay on top of production without the chaos.

2. How does it make production more efficient?

It helps you spot problems before they snowball by giving you live updates on materials, tasks, and machine performance. This way, you can quickly address any issues, avoid delays, and keep things moving without a hitch.

3. Can small businesses use manufacturing management software?

Absolutely! There are plenty of affordable options designed for small businesses. They help streamline operations without the complexity of larger systems, giving you the tools to stay organized and efficient without breaking the bank.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.