Medical Equipment Maintenance Tracking Using IT Asset Management

Learn how to implement ITAM to streamline medical equipment maintenance, reduce downtime, and improve patient care with these simple steps.

Medical equipment is crucial in healthcare, but keeping track of its maintenance can be challenging. When equipment breaks down, it can cause delays, added costs, and safety risks.

Many healthcare facilities still rely on paper logs or outdated systems, leading to mistakes and missed deadlines. IT Asset Management software simplifies this by organizing equipment data, scheduling maintenance, and ensuring everything runs smoothly.

How Does ITAM Apply to Medical Equipment?

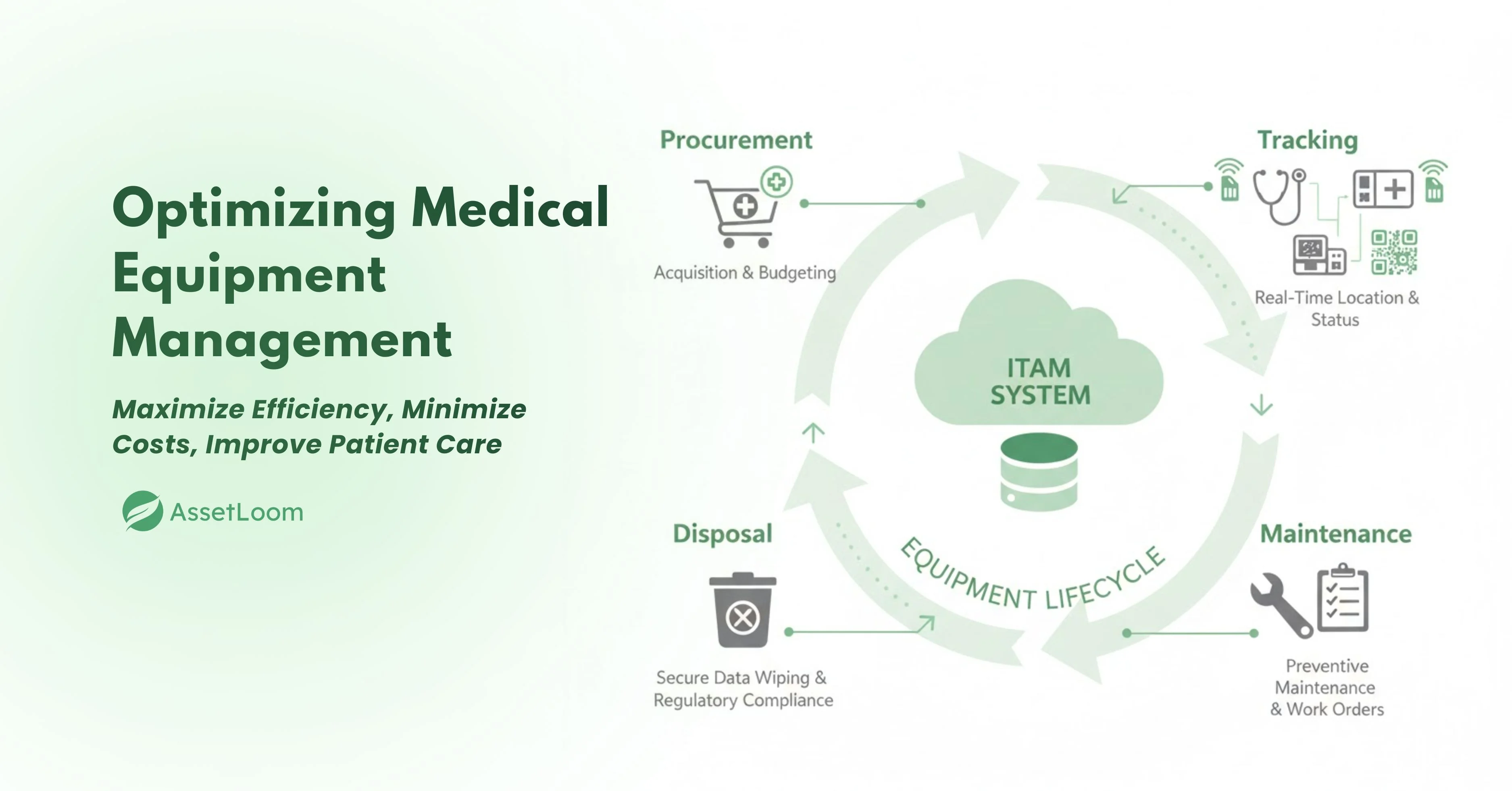

IT Asset Management (ITAM) is a system used to manage the full lifecycle of medical equipment, from purchase to retirement. In healthcare, ITAM ensures that medical devices are properly maintained, secure, and comply with regulations. It helps improve patient safety, reduce risks, and ensure equipment is always available when needed.

Key Applications of ITAM for Medical Equipment

Lifecycle Management

ITAM tracks medical equipment through its entire lifecycle to ensure safety and efficiency:

- Procurement: Ensures the purchase of equipment that fits with existing systems and meets security standards.

- Inventory Management: Keeps a real-time inventory of all devices, showing their location, status, and usage. Technologies like RFID help with real-time tracking.

- Maintenance: Automates maintenance scheduling and tracks service history to reduce downtime and prevent costly repairs.

- Disposal: Manages the secure disposal of devices, including erasing any sensitive patient data (PHI).

Software Management

Many modern medical devices rely on software. ITAM ensures that the software is updated, secure, and compliant:

- Software Updates: Automates updates to keep devices secure and functional.

- Software as a Medical Device (SaMD): Tracks apps or software that directly serve a medical purpose, like health-monitoring apps.

- Integration: Ensures that device software works smoothly with hospital IT systems, such as Electronic Health Records (EHRs).

Cybersecurity and Risk Mitigation

As more devices connect to the internet (Internet of Medical Things, or IoMT), protecting them from cyber threats becomes crucial:

- Vulnerability Management: Identifies devices that may be outdated or insecure and helps replace them.

- Access Control: Makes sure only authorized personnel can access devices and sensitive data.

- Continuous Monitoring: Tracks device activity to spot any suspicious access or security breaches.

- Disaster Recovery: Includes medical devices in recovery plans to ensure services can be quickly restored during an emergency.

Regulatory Compliance

Healthcare is highly regulated, and ITAM helps meet these requirements:

- Audit-Ready Reporting: Automatically generates reports for internal and external audits.

- Data Security: Helps secure patient data according to regulations like HIPAA by classifying assets and applying security controls.

Cost and Operational Efficiency

ITAM not only improves safety but also helps optimize costs and operations:

- Reduced Downtime: Proactive maintenance ensures that equipment is ready to use, minimizing delays.

- Cost Optimization: Helps identify underused or unnecessary equipment and makes purchasing more cost-effective.

- Better Patient Care: Ensures reliable, up-to-date technology is always available, allowing staff to focus on patients.

How ITAM Works for Medical Equipment Maintenance Tracking

ITAM systems help healthcare organizations track and manage their medical equipment more efficiently. Here’s how it works:

1. Data Integration

ITAM systems collect data from different sources to provide a complete view of each device:

- Manual entry: Staff can input equipment details, such as make, model, and location.

- Real-Time Data: IoT sensors and technologies like RFID or barcodes provide live updates about the equipment’s condition and location.

2. Centralized Control

ITAM systems store all asset information in one central location. This makes it easier to:

- Access real-time updates about the equipment’s status and maintenance needs.

- View the full history of each asset, from purchase to repairs.

- Monitor equipment across different departments and locations in the healthcare facility.

3. Automated Workflow

Based on the data collected, the ITAM system can automate various tasks:

- Maintenance Scheduling: Automatically schedules preventive maintenance and alerts staff when it’s time for inspections or repairs.

- Work Orders: When maintenance is needed, the system can automatically generate work orders and assign them to the appropriate team members.

- Reporting: The system can create maintenance reports, usage logs, and compliance records, reducing the time spent on manual reporting.

By automating these tasks, ITAM reduces human errors, ensures timely maintenance, and helps avoid costly repairs or downtime. The real-time tracking and data-driven decisions help improve overall operational efficiency.

Benefits of Medical Equipment Maintenance Tracking Using ITAM

Using IT Asset Management (ITAM) for medical equipment maintenance brings several important benefits to healthcare organizations. Here’s how it helps:

1. Less Downtime

- Preventive Maintenance: ITAM systems schedule regular check-ups to stop equipment from breaking down unexpectedly.

- Fewer Emergency Repairs: Timely maintenance helps avoid last-minute repairs and disruptions.

- Quick Fixes: When problems happen, ITAM helps identify and fix them faster, reducing downtime.

2. Longer Equipment Life

- Regular Check-Ups: ITAM ensures equipment gets serviced on time, which helps it last longer.

- Track Performance: ITAM helps spot problems early, so they can be fixed before equipment fails.

3. Cost Savings

- Avoid Expensive Repairs: Preventive maintenance helps avoid costly emergency repairs.

- Better Equipment Use: ITAM shows which equipment is underused or outdated, helping you make smarter decisions about replacements.

- Efficient Use of Resources: ITAM helps you allocate resources better, cutting waste and saving money.

4. Easier Compliance

- Track Regulations: ITAM makes sure all maintenance is properly logged, helping meet healthcare regulations like HIPAA.

- Ready for Audits: ITAM creates accurate reports, making it easier to pass audits with less work.

5. Better Patient Care

- Reliable Equipment: Well-maintained equipment means healthcare staff can count on it to provide quality care.

- Streamlined Operations: ITAM reduces time spent on equipment issues, allowing staff to focus more on patients.

By using ITAM, healthcare organizations can reduce downtime, save money, improve compliance, and offer better care to patients.

Read also: How Healthcare Teams Benefit from a Cloud-Based Asset Management System

How to Implement ITAM for Medical Equipment Maintenance Tracking

To set up an effective IT Asset Management (ITAM) system for medical equipment maintenance, healthcare organizations must follow clear steps. The goal is to maximize equipment uptime, improve patient safety, and ensure compliance with regulations.

![]()

1. Plan and Define Goals

- Form a Project Team: Involve key stakeholders from clinical engineering, IT, and maintenance departments to outline the project’s requirements.

- Conduct an Audit: Perform a full audit of all medical equipment, noting the location, status, and condition of each device.

- Define Clear Objectives: Decide on your goals, such as:

- Reducing equipment downtime.

- Lowering maintenance costs.

- Ensuring compliance with industry regulations (e.g., FDA, Joint Commission).

- Enhancing patient safety.

- Optimizing equipment usage.

2. Choose the Right Software

- Select a Computerized Maintenance Management System (CMMS) or IT Asset Management solution tailored to healthcare needs.

- Key Features to Look For:

- Asset Registry: A central database that tracks equipment, including details like make, model, service history, and warranties.

- Work Order Management: A system to generate, assign, track, and close maintenance requests.

- Preventive Maintenance (PM) Scheduling: Automates scheduling of routine checks based on manufacturer recommendations or equipment usage.

- Compliance Reporting: Simplifies audit trails and regulatory reports.

- Inventory Management: Tracks parts and consumables used in maintenance.

- Mobile Accessibility: Allows technicians to view and update work orders in the field.

- Cloud vs. On-Premise: Cloud-based systems offer accessibility and lower upfront costs, while on-premise solutions may provide more control over data.

Read also: Top 10 Medical Equipment Tracking Software in 2025

3. Track and Tag Equipment

- Tag Equipment: Use barcodes or QR codes on each piece of equipment for easy scanning.

- Advanced Tracking (Optional): For high-value or frequently moved equipment, use Radio-Frequency Identification (RFID) or Real-Time Location Systems (RTLS) to automate location tracking and prevent theft.

4. Establish Standard Operating Procedures (SOPs)

- Create SOPs for each stage of the equipment lifecycle:

- Acquisition: Register new equipment in the system when it arrives.

- Maintenance:

- Reactive Maintenance: Set up workflows for reporting and fixing broken equipment.

- Preventive Maintenance: Develop standardized schedules and checklists for regular maintenance tasks.

- Disposal: Establish procedures for retiring assets, including secure data wiping and proper disposal.

5. Train Staff and Integrate with Existing Systems

- Staff Training: Ensure all relevant personnel, including technicians and nurses, are trained on how to use the new ITAM system.

- System Integration: Integrate your CMMS/EAM with other hospital systems (e.g., Enterprise Resource Planning or hospital management systems) for smooth data flow.

6. Measure and Optimize

- Track KPIs: Use data and reports to measure key performance indicators (KPIs) like:

- Mean Time to Repair (MTTR): Average time taken to fix equipment.

- PM Compliance: Percentage of preventive maintenance tasks completed on time.

- Asset Utilization Rate: How often equipment is in use versus idle.

- Regular Audits: Perform audits to ensure accurate data and equipment location.

- Optimize Processes: Use insights from KPIs and audits to improve maintenance strategies and identify inefficiencies.

By following these steps, you can successfully implement ITAM for medical equipment maintenance, improving overall operations and patient care.

Real-World Examples of ITAM in Medical Equipment Maintenance

Here are some examples of healthcare organizations that successfully used ITAM systems for medical equipment maintenance.

1. Reducing Downtime in a Large Hospital Network

- A large hospital network started using an ITAM system to track medical equipment across multiple locations. They used RFID technology to track equipment in real time.

- Results: Downtime was cut by 30%. The hospital could schedule maintenance better and quickly identify issues, ensuring equipment was always ready when needed.

2. Improving Compliance in a Healthcare Facility

- A regional healthcare facility used ITAM to help meet regulatory requirements like HIPAA and FDA standards. They used the software’s automated reporting features to simplify audits and track maintenance records.

- Results: The facility passed audits easily. The system helped them stay up-to-date on maintenance and compliance, saving time and reducing the risk of penalties.

3. Cost Savings in a Multi-Department Medical Center

- A medical center with several departments had trouble with underused equipment. After using ITAM, they tracked asset use across departments and identified equipment that was not being fully used.

- Results: Equipment purchasing costs were reduced by 20%. By moving unused devices to departments that needed them, they saved money and improved resource use.

4. Enhancing Patient Safety in a Teaching Hospital

- A teaching hospital adopted ITAM to track both equipment and maintenance schedules. The system automated regular maintenance and tracked service history for critical equipment.

- Results: Emergency equipment failures were greatly reduced. Routine maintenance became more reliable, and the hospital ensured life-saving equipment was always ready for use.

These examples show how ITAM can help healthcare facilities reduce downtime, improve compliance, save costs, and enhance patient safety. By using ITAM, organizations can better manage their equipment and provide more reliable care.

Conclusion

IT Asset Management (ITAM) brings many benefits to managing medical equipment and maintenance in healthcare. It helps automate tasks, provide real-time data, and ensure equipment is reliable and ready to use.

The main benefits of using ITAM are:

- Less Downtime: Regular maintenance reduces sudden equipment failures.

- Better Compliance: Automated reports make it easier to meet regulations.

- Cost Savings: ITAM helps optimize equipment use and reduce repair costs.

- Improved Patient Care: Reliable equipment allows staff to focus on patient care.

While there are challenges, like ensuring accurate data and getting staff to adopt the system, the benefits are worth the effort. With the right planning, training, and ongoing maintenance, ITAM can improve your equipment management, increase efficiency, and help you provide better care.

If you're thinking about using ITAM, start with clear goals, pick AssetLoom software, and keep track of the system’s performance to get the best results.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.