Equipment Maintenance Log: Definition & Business Benefits

Discover the definition of an equipment maintenance log, the types available, and the key business benefits of keeping accurate maintenance records.

Think about the equipment your business uses every day: the machines on the shop floor, the laptops on desks, or the vehicles that keep things moving. When that equipment breaks down, work slows down or stops altogether. The fix usually costs time, money, and sometimes even customer trust.

That is why many businesses rely on something simple but powerful: an equipment maintenance log. It is not a complicated tool, just a structured way to track what has been fixed, what has been checked, and what needs attention next. Over time, this record helps businesses keep their equipment running longer, safer, and at a lower cost.

In this article, we will break down what an equipment maintenance log is, the types you can use, what goes into it, and the real benefits it brings to your business.

What Is an Equipment Maintenance Log?

An equipment maintenance log is a structured record used to document all maintenance activities performed on equipment. It typically includes details such as the date of service, the type of maintenance, parts repaired or replaced, and the name of the person who carried out the work. Over time, the log builds a complete history for each asset, showing exactly how and when it has been maintained.

Maintenance logs can be categorized in two main ways: by the format used to keep them and by the type of maintenance they are designed to track.

By Format

Some organizations keep maintenance logs on paper, using notebooks or printed forms. These are easy to set up but can be hard to organize over the long term. Others use spreadsheets, which offer more flexibility but still require manual updates.

Increasingly, businesses are turning to software-based logs that can automate entries, create reminders, and generate reports. In many cases, these digital logs are part of broader equipment management software, which connects maintenance records with inventory and asset tracking in a single system. In industries with strict regulations, such as healthcare or manufacturing, specialized logs are also used to meet compliance standards.

By Maintenance Approach

Maintenance logs can also be grouped by the kind of maintenance they capture:

- Basic log: Records only essential information such as the date, maintenance task, and responsible person.

- Detailed log: Provides additional context like equipment ID, location, replaced parts, and follow-up notes.

- Preventive maintenance log: Tracks scheduled tasks that are designed to reduce the chance of failure, such as inspections or lubrication.

- Predictive maintenance log: Uses data from sensors and monitoring tools, like temperature or vibration readings, to plan maintenance based on actual equipment condition.

- Corrective maintenance log: Records repairs and corrective actions taken after equipment has broken down or failed.

By looking at both the format and the approach, businesses can choose the type of maintenance log that fits their operations best, whether they need something simple or a system built for more advanced maintenance planning.

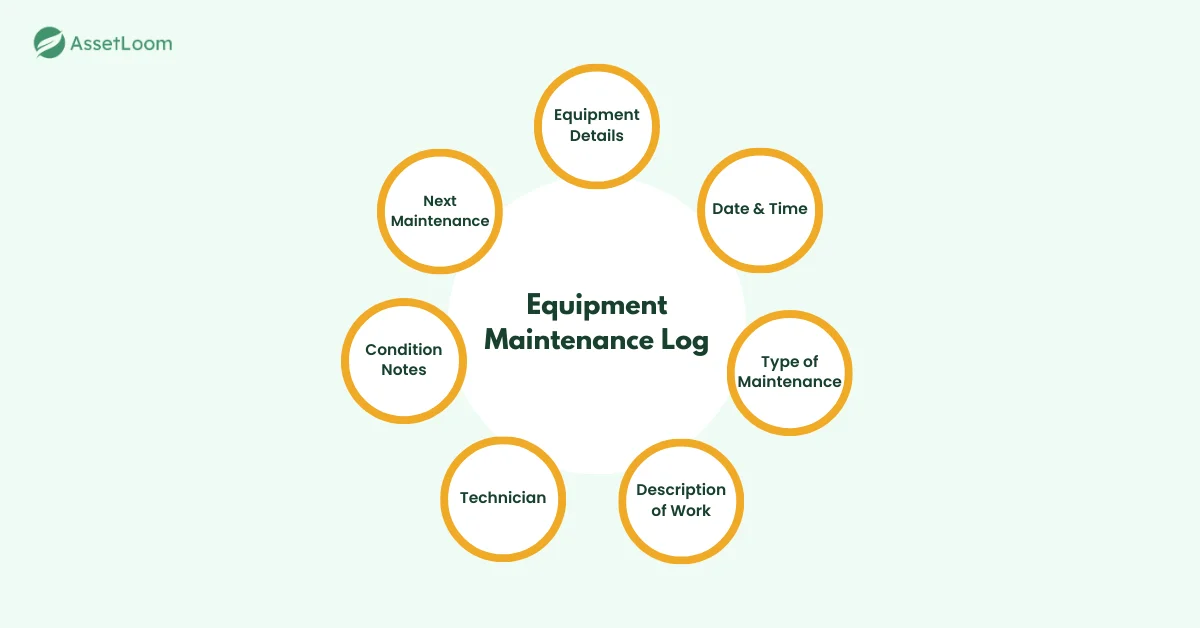

Key Details in an Equipment Maintenance Log

A maintenance log is only useful if it captures the right details. The information recorded should give a clear picture of the equipment’s condition and the work that has been done on it. While the exact format may vary, most logs include the following elements:

- Equipment details: Basic identifiers such as name, model, serial number, and location.

- Date and time: When the maintenance activity took place.

- Type of maintenance: Whether it was an inspection, repair, preventive check, or another type of service.

- Description of work: Notes on the task performed, including parts that were replaced or adjusted.

- Technician or responsible person: The name of the individual or team who carried out the work.

- Condition notes: Observations about the equipment’s current state or performance.

- Next scheduled maintenance: Information on when the next service should occur.

Keeping these details consistent helps create a reliable history for each piece of equipment. It also ensures that anyone reviewing the log, whether a technician, manager, or auditor, can quickly understand the status of the asset.

Why Businesses Use an Equipment Maintenance Log

For many organizations, an equipment maintenance log is more than just paperwork. It acts as a reliable reference point that shows what has been done, when it was done, and by whom. This consistency prevents confusion, especially when multiple people are responsible for maintaining the same equipment.

Another reason businesses keep maintenance logs is to avoid missed tasks. Without a clear record, inspections or repairs can easily be delayed or overlooked. A log provides structure, making sure that routine checks and servicing happen on time.

Maintenance logs are also important for accountability. They document who carried out each task, which is useful for both internal management and external audits. In regulated industries, these records may even be required to demonstrate compliance with safety and quality standards.

Finally, having a log available gives managers better visibility. When equipment issues come up, they can quickly check the history, see patterns, and decide whether it is time for a repair, replacement, or upgrade.

Business Benefits of an Equipment Maintenance Log

Keeping an accurate equipment maintenance log does more than organize records. It directly supports reliability, cost control, compliance, and smarter planning. Here are the key benefits in more detail:

Improved Reliability

When every inspection and repair is documented, equipment is less likely to fail unexpectedly. A log makes it easier to track recurring issues and identify patterns over time. For example, if the same part has been replaced multiple times, managers can investigate the root cause before it leads to major downtime.

Cost Efficiency

Unexpected breakdowns often bring high costs, from emergency repair bills to lost productivity. A maintenance log helps businesses avoid these situations by ensuring work is scheduled before problems escalate. In the long run, this approach reduces repair costs, minimizes waste, and delays expensive replacements.

Compliance and Safety

Many industries have strict rules about how often equipment must be inspected or serviced. A maintenance log provides clear evidence that these tasks were completed on schedule. This is not only useful for passing audits but also helps protect employee safety and reduce liability in case of accidents.

Longer Asset Lifespan

Regular care extends the usable life of equipment. By keeping track of tasks such as lubrication, calibration, or replacing worn parts, a log ensures that assets stay in good condition for longer. This means businesses get more value from their investments before needing to buy replacements.

Better Decision-Making

A detailed log gives managers reliable data to base decisions on. Instead of guessing whether to repair or replace equipment, they can look at the full maintenance history. If a machine has frequent repairs, it may be time to upgrade. If it has been reliable, managers can plan confidently to keep it in service.

Taken together, these benefits show that a maintenance log is more than an administrative tool. It helps businesses reduce risks, control costs, and make well-informed choices that support long-term success.

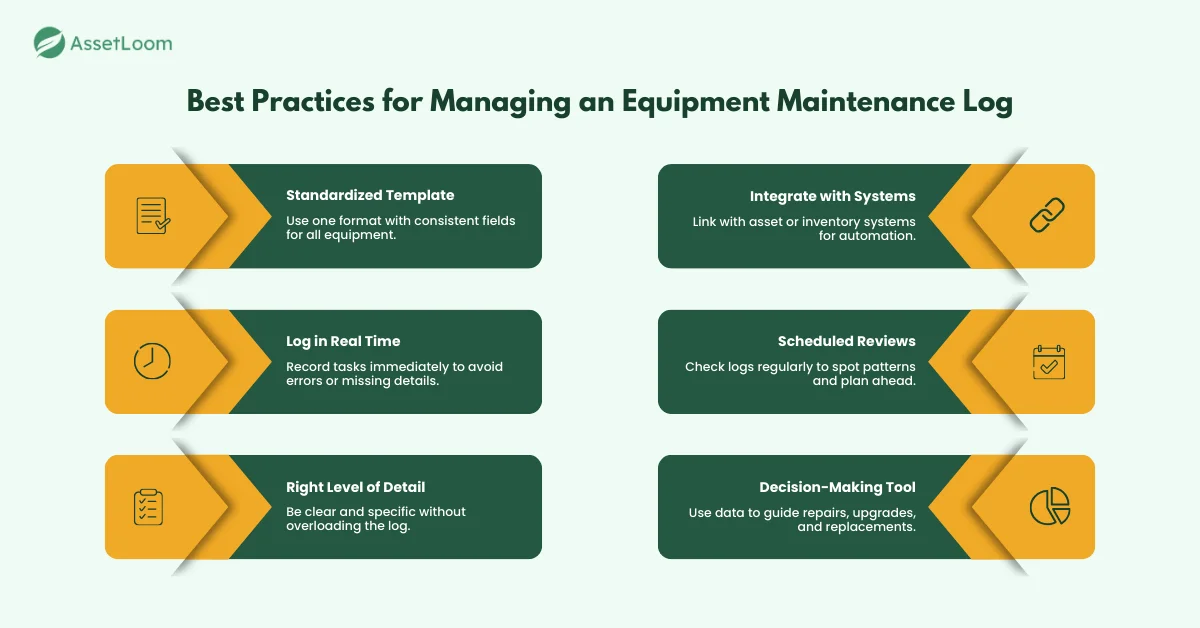

Best Practices for Managing an Equipment Maintenance Log

An equipment maintenance log can either be a simple record-keeping tool or a powerful source of insight, depending on how it is managed. To get the most value, businesses should apply practices that focus on consistency, detail, and integration. Here are some actionable strategies:

1. Create a Standardized Template

A common mistake is letting each department or technician record information in their own style. This leads to incomplete or inconsistent entries that are hard to compare later. A standardized template avoids this problem by ensuring that everyone records the same core information: equipment ID, model number, location, maintenance type, date, description of work, technician name, and next service date.

Practical example: A manufacturing company uses one shared template across all plants, so managers can compare performance and maintenance costs for similar machines in different locations.

2. Log Maintenance in Real Time

Delays in recording often lead to forgotten details or vague descriptions. Logging in real time ensures accuracy. Encourage technicians to enter information immediately after performing the task, whether that means updating a paper log on the shop floor or entering it into a mobile app.

Practical example: An HVAC service team uses tablets to update logs right after servicing equipment, ensuring that even small adjustments like filter replacements are recorded.

3. Provide the Right Level of Detail

Too little detail makes the log useless, while too much can bury important information. Entries should go beyond “repaired” or “checked” and specify what was done, why, and what parts were involved. However, avoid long narratives that make the log difficult to read.

Practical example: Instead of “Pump serviced,” a detailed entry would read: “Replaced pump seal due to leakage, checked bearings, no further issues detected. Next inspection scheduled in 6 months.”

4. Integrate with Other Systems

A standalone log is helpful, but integration multiplies its value. Linking the maintenance log with asset management, inventory, or procurement systems allows for automated reminders, easier tracking of spare parts, and a clearer view of overall asset health.

Practical example: A hospital integrates its maintenance logs with its inventory system. When a technician records that a replacement part was used, the system automatically updates stock levels and triggers a reorder if supplies run low.

5. Review Logs on a Set Schedule

Logs are not meant to be filed away and forgotten. Regular reviews help spot patterns and recurring issues. Monthly reviews can reveal which equipment requires the most attention, while quarterly reviews can inform budgeting and replacement planning.

Practical example: A logistics company noticed through quarterly log reviews that a specific model of forklift had repeated brake failures. They used this data to negotiate a warranty claim and adjust future purchasing decisions.

6. Use Logs as a Decision-Making Tool

Finally, businesses should treat the log as more than a compliance requirement. When used actively, it can highlight aging assets, justify upgrades, and improve maintenance scheduling. Decision-makers who use log data to guide strategies often see significant reductions in downtime and costs.

Practical example: A food processing plant used log data to predict when certain machines were likely to fail. By replacing them proactively, they cut unplanned downtime by half.

By applying these practices, an equipment maintenance log becomes more than a checklist. It turns into a central tool for improving reliability, controlling costs, and supporting strategic decisions about equipment across the organization.

Conclusion

An equipment maintenance log is more than a record of past work. It provides a structured way to track service history, keep equipment reliable, and plan ahead. Beyond documentation, it supports compliance, reduces costs, and extends asset life.

For any organization that depends on equipment, maintaining a log is a simple step that delivers long-term value.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox