Difference Between Machine Maintenance Software and ITAM Software

Machine Maintenance Software and ITAM Software are specialized tools for asset management, each tailored to distinct types of assets and organizational needs.

Machine Maintenance Software and ITAM (IT Asset Management) Software are specialized tools for asset management, each tailored to distinct types of assets and organizational needs.

At first glance, they might seem similar because both involve managing assets. But in reality, they focus on very different areas. Machine Maintenance Software is designed to keep industrial equipment and machinery running smoothly, while ITAM software manages the lifecycle of IT assets like computers, servers, and software.

What is Machine Maintenance Software?

Machine Maintenance Software, sometimes called Equipment Maintenance Software, is a centralized system built to plan, execute, and monitor maintenance tasks for physical, non-IT assets. It plays a critical role in asset-heavy industries such as manufacturing, healthcare, logistics, retail, and facilities management (FM)—where machine uptime directly impacts business performance.

The main goal of this software is to minimize unplanned breakdowns and keep equipment in peak condition. It does this by supporting preventive, predictive, and corrective maintenance strategies. For example:

- Preventive Maintenance: Schedule routine servicing based on time or usage to avoid sudden failures.

- Predictive Maintenance: Use real-time data from sensors to predict potential breakdowns before they happen.

- Corrective Maintenance: Manage repairs efficiently when unexpected issues occur.

Modern Machine Maintenance Software often integrates with other business systems such as ERP (Enterprise Resource Planning), SCADA/BMS (Supervisory Control and Data Acquisition/Building Management Systems), and procurement platforms, enabling automated workflows and real-time updates.

What is IT Asset Management (ITAM) Software?

IT Asset Management Software is a system designed to track, manage, and optimize the lifecycle of IT assets within an organization. These assets include devices like **laptops, desktops, servers, networking equipment**, and intangible resources such as **software licenses, cloud subscriptions, and digital services**.

The primary purpose of ITAM software is to give businesses complete visibility into their IT environment, ensuring assets are properly utilized, compliant with licensing rules, and cost-effective throughout their lifecycle.

Unlike Machine Maintenance Software, which focuses on the operational health of physical equipment, ITAM emphasizes ownership, compliance, and financial management of IT resources.

Key Functionalities and Features

Machine Maintenance Software

Machine Maintenance Software offers a range of functionalities tailored to physical asset management:

- Maintenance Scheduling: Supports condition-based, usage-based, and time-based preventive maintenance, allowing users to set automatic recurrences (e.g., daily, weekly, monthly) or based on meter readings.

- Performance Tracking: Tracks equipment usage, performance data, and maintenance history to optimize operations and reduce downtime.

- Cost Monitoring: Monitors maintenance costs and identifies cost-saving opportunities through efficient resource allocation.

- Inventory Management: Manages inventory of spare parts, integrating with procurement systems for real-time parts availability checks.

- Reporting and Analytics: Generates detailed reports for decision-making, such as downtime analysis and maintenance KPIs.

- User Accessibility: Fully mobile-enabled, with offline-ready apps, tap-to-tag asset scans, voice inputs, image uploads, and one-click status updates for field technicians.

ITAM Software

ITAM Software, on the other hand, focuses on IT asset lifecycle management with features such as:

- Asset Discovery and Tracking: Performs hardware and software inventory, including network scans to find servers, PCs, laptops, and other networked devices, with automatic gathering of installed software information.

- Software License management: Ensures software license compliance by tracking usage, conducting audits, and managing license terms to avoid over-licensing and non-compliance penalties.

- Compliance and Risk Management: Identifies security vulnerabilities, ensures regulatory compliance (e.g., data privacy regulations), and mitigates risks through proper patching and inventory updates.

- Cost Management: Provides cost tracking and budget forecasting for IT assets, optimizing resource allocation and identifying cost-saving opportunities.

- IT Asset lifecycle Management: Manages assets from procurement to disposal, including maintenance, upgrades, and retirement, to maximize ROI and minimize disruptions.

Integration and User Accessibility

Machine Maintenance Software integrates with a variety of systems to enhance functionality:

- It can connect with ERP systems ERP systems for financial and operational data, SCADA/BMS for real-time equipment monitoring, and procurement and inventory platforms for automated work order creation and parts availability checks. This integration ensures seamless workflows and real-time data access, crucial for asset-intensive environments.

ITAM Software typically integrates with IT systems, service desks, and financial systems to facilitate IT asset tracking and compliance:

- It often integrates with ITSM solutions for service delivery and incident management, and with financial systems for cost tracking and budget forecasting. This ensures a holistic view of IT assets and their financial impact, supporting informed decision-making.

In terms of user accessibility, Machine Maintenance Software is designed for field technicians with fully mobile-enabled, offline-ready apps, offering features like tap-to-tag asset scans, voice inputs, image uploads, and one-click status updates, ensuring usability in remote or disconnected environments. ITAM Software, while also accessible via mobile and desktop platforms, is typically used by IT managers and teams, focusing on administrative tasks like asset tracking and compliance reporting, with less emphasis on field operations.

Industries Served and Examples

Both Machine Maintenance Software and IT Asset Management (ITAM) Software cater to different business needs based on the types of assets involved. Here’s how they are used across industries:

Machine Maintenance Software

Machine Maintenance Software serves organizations that rely heavily on physical, non-IT assets to maintain operational efficiency. Its primary goal is to ensure uptime, extend equipment life, and reduce costly breakdowns.

Key Industries:

Manufacturing:

- Manages production machinery, assembly lines, robotic systems.

- Enables predictive maintenance to reduce production stoppages.

Healthcare:

- Tracks diagnostic tools, imaging systems, surgical equipment.

- Ensures compliance with safety and regulatory standards.

Facilities Management (FM):

- Maintains HVAC systems, elevators, energy management systems.

- Integrates with BMS (Building Management Systems) for real-time alerts.

Logistics & Transportation:

- Manages fleet vehicles, forklifts, conveyor belts.

- Tracks mileage and service schedules to optimize delivery operations.

Retail Chains: Keeps refrigeration units, point-of-sale (POS) systems, display equipment operational.

Construction: Handles cranes, bulldozers, power tools, and on-site heavy machinery.

Popular Machine Maintenance Software Examples:

- Fiix – Preventive and predictive maintenance with IoT integration.

- UpKeep – Mobile-first CMMS for field technicians.

- Limble CMMS – Known for its intuitive dashboards and QR-code asset tagging.

- Facilio – Integrates with BMS for real-time maintenance.

- eMaint CMMS, MPulse, Maintenance Connection – Enterprise CMMS solutions for large-scale operations.

- SafetyCulture, Whip Around – Focused on compliance and fleet inspections.

IT Asset Management Software

ITAM software is essential for businesses that depend on digital and IT infrastructure, ensuring control over hardware, software, and cloud assets. It is critical for security, compliance, and cost optimization.

Key Industries:

- Technology: Software development companies managing servers, virtual machines, and cloud services.

- Finance & Banking: Tracks secure IT systems, ensures compliance with data protection laws, and monitors licenses.

- Healthcare: Maintains hospital IT systems, patient databases, and connected medical devices.

- Manufacturing: Oversees computers, industrial IoT devices, and production IT systems.

- Education: Manages thousands of student devices, campus networks, and e-learning platforms.

- Government & Large Enterprises: Handles massive hardware inventories and strict compliance requirements.

Popular ITAM Software Examples:

- AssetLoom – Comprehensive IT asset lifecycle management with cost optimization.

- ServiceNow ITAM – Enterprise-grade IT asset discovery and compliance.

- Freshservice – ITAM integrated with IT Service Management (ITSM) for streamlined workflows.

- Lansweeper – Advanced asset discovery and network scanning.

- Alloy, ManageEngine Endpoint Central – Focused on unified IT asset visibility and endpoint management.

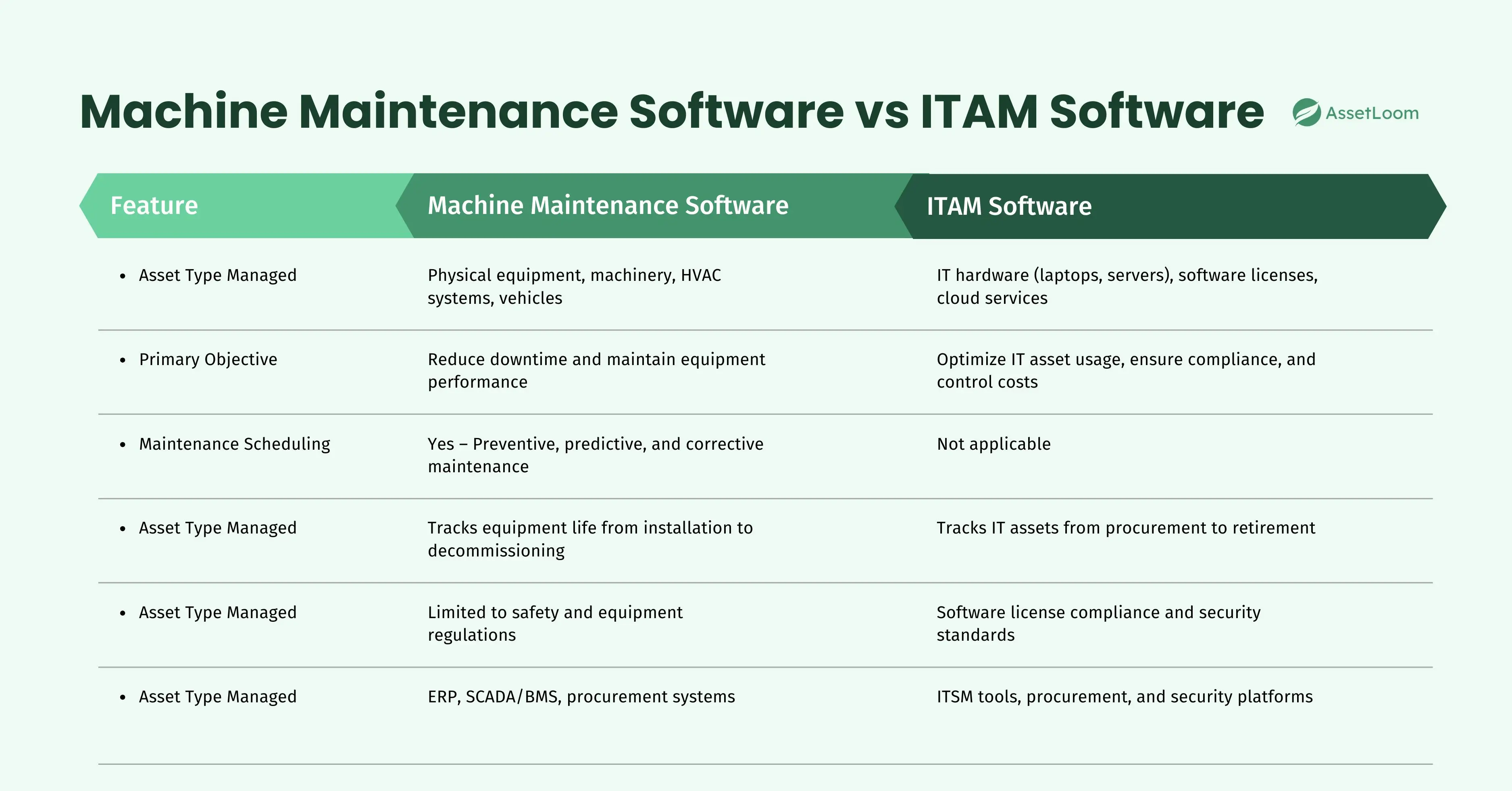

Core Differences Between MMS and ITAM Software

While both tools aim to improve asset efficiency, their focus areas and functionalities differ significantly. Here’s a side-by-side comparison:

| Aspect | Machine Maintenance Software | IT Asset Management (ITAM) Software |

|---|---|---|

| Primary Purpose | Maintain physical, non-IT assets for operational efficiency | Manage IT assets throughout their lifecycle for visibility, compliance, and cost control |

| Asset Type | Industrial machines, vehicles, HVAC systems, building infrastructure | Hardware (PCs, servers), software licenses, cloud services |

| Core Functions | Preventive & predictive maintenance, work order management, downtime tracking | Asset discovery, license compliance, cost management, lifecycle tracking |

| Maintenance Focus | Ensures machines operate efficiently and minimize downtime | Ensures IT assets are compliant, secure, and optimally used |

| Industries Served | Manufacturing, healthcare, logistics, retail, construction | IT, finance, healthcare, education, enterprises |

| Key Integrations | ERP, SCADA/BMS, procurement systems | ITSM tools, procurement, security platforms |

| Examples | Fiix, UpKeep, Limble CMMS, Facilio | AssetLoom, ServiceNow, Freshservice, ManageEngine |

Conclusion

Machine Maintenance Software and IT Asset Management (ITAM) Software may both fall under the umbrella of asset management, but their focus is entirely different. Machine Maintenance Software is designed for physical, non-IT assets like machines, HVAC systems, and fleet vehicles, ensuring they run efficiently and experience minimal downtime. On the other hand, ITAM Software handles IT assets across their entire lifecycle, ensuring compliance, security, and cost optimization.

If your organization relies heavily on IT systems, investing in a robust ITAM solution can help you gain visibility, reduce costs, and ensure compliance.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox