Mobile Device Inventory Management for Retail Stores and Warehouses

How mobile device inventory management helps retail stores and warehouses track devices, reduce downtime, and improve daily operations.

Retail stores and warehouses depend on mobile devices more than ever. From barcode scanners used during stock counts to tablets at checkout counters, these tools are part of everyday work.

The problem is that many businesses struggle to keep track of them. Devices go missing, get damaged, or sit unused in a corner. Replacements can be expensive, and downtime during busy hours can be frustrating for both staff and customers.

Mobile device inventory management helps solve these issues by giving businesses a clear way to track, assign, and maintain every device. It keeps equipment available when it’s needed most and reduces the stress of unexpected losses.

What is Mobile Device Inventory Management?

Mobile device inventory management is a component of a broader practice known as IT inventory management. It focuses on tracking and managing the handheld tools your business depends on, such as smartphones, tablets, barcode scanners, and point-of-sale devices.

The main idea is simple: know what devices you own, where they are, and who is using them. By connecting this to IT inventory management, you get a complete view of both your mobile devices and the rest of your technology assets.

For retail stores and warehouses, this means more than just keeping count. It ensures employees always have the right tools available, reduces the risk of loss, and helps daily operations run more smoothly.

IT Inventory Management Explained under 8 MINUTES

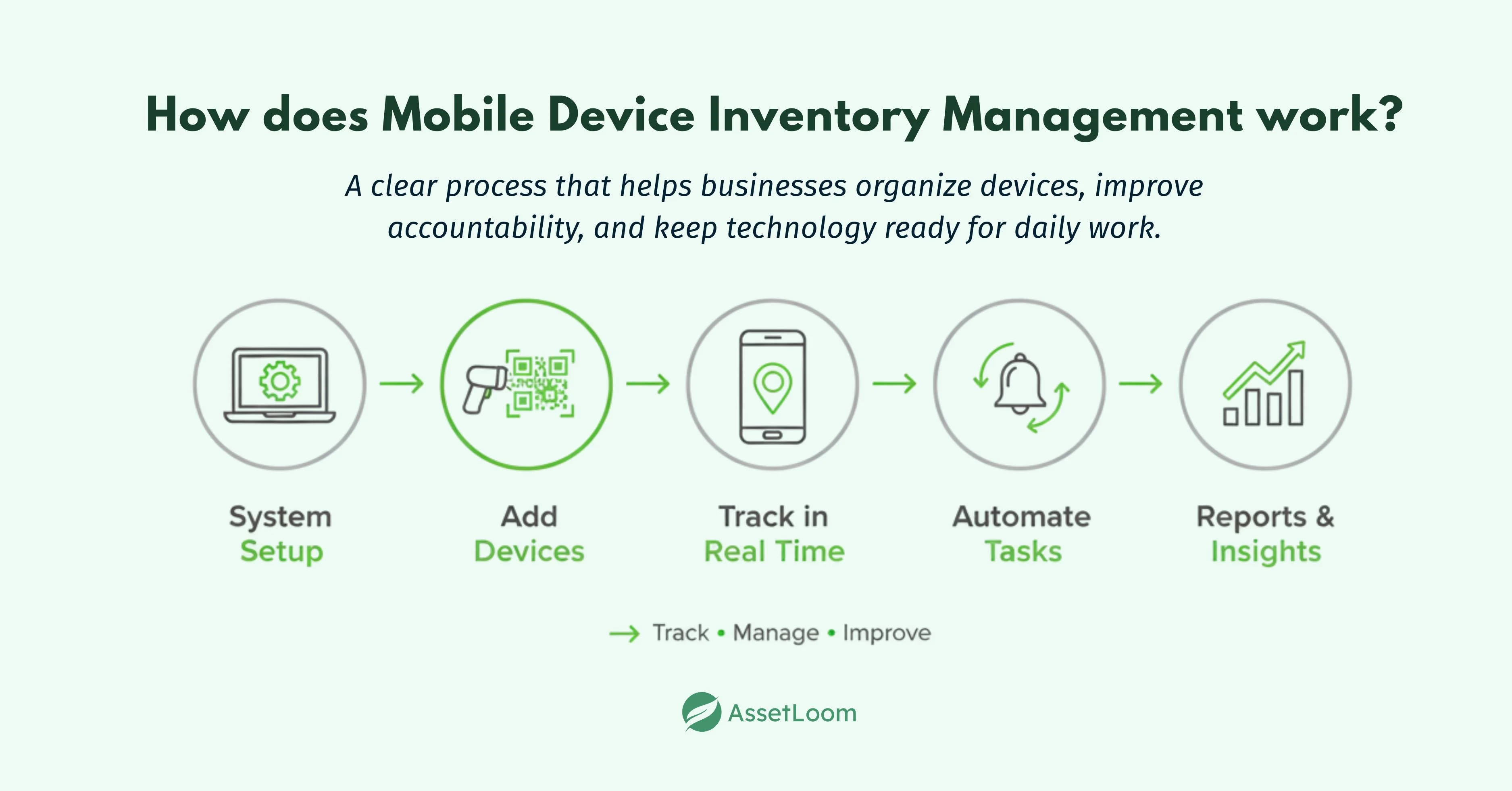

How does Mobile Device Inventory Management work?

Mobile Device Inventory Management is a step-by-step process that helps businesses track, manage, and care for all their devices. Here’s how it usually works:

1. Setting up the system

The first step in mobile device inventory management is choosing the right system to keep everything organized. Some businesses use cloud-based software, while others prefer mobile apps or tools that connect directly with their existing IT inventory management system.

During setup, managers define important details such as device categories, user accounts, and security rules. This foundation makes it possible to track devices accurately and ensure every phone, tablet, or scanner is connected to the system from day one.

2. Adding and categorizing devices

Once the system is ready, the next step is to enter details for every device the business owns. This usually includes information like the model, operating system, serial number, and purchase date. Some systems allow faster input using tools such as QR codes or barcode scanning.

After the devices are added, they are grouped into categories. For example, tablets used at checkout might be in one group, while barcode scanners in the warehouse belong in another. Devices can also be sorted by department or by whether they are company-owned or part of a bring-your-own-device (BYOD) policy.

This organization makes it much easier to find devices in the system and to understand how they are being used across the business.

3. Tracking devices in real time

After devices are added, the system starts monitoring them as they are used. Each device can be tracked for details like location, status, and who is currently using it. This creates accountability and reduces the chance of devices being misplaced.

Real-time tracking also helps managers know which devices are active, which are sitting idle, and which may need attention. For example, a scanner that hasn’t been checked in after a shift can be flagged right away.

By keeping this information up to date automatically, businesses avoid guesswork and can quickly respond when a device goes missing or needs repair.

4. Automating routine tasks

A good inventory management system does more than just record information. It can also take care of routine tasks automatically. For example, the system can send reminders for software updates, schedule maintenance, or alert managers when a device hasn’t been checked in.

Automation reduces the amount of manual work for staff and lowers the chance of human error. It also ensures that important tasks like repairs or security updates are not overlooked, keeping devices reliable and ready for use.

5. Reporting and learning from the data

The final step is using the system’s reporting features to understand how devices are being used. Reports can show details such as how long devices last, how often they need repairs, and which departments rely on them the most.

These insights help managers make better decisions. For example, they might learn that certain devices are underused and don’t need to be replaced, or that some teams need more equipment during busy seasons.

By analyzing this data over time, businesses can reduce unnecessary costs, extend the life of their devices, and make sure technology supports daily operations in the best way possible.

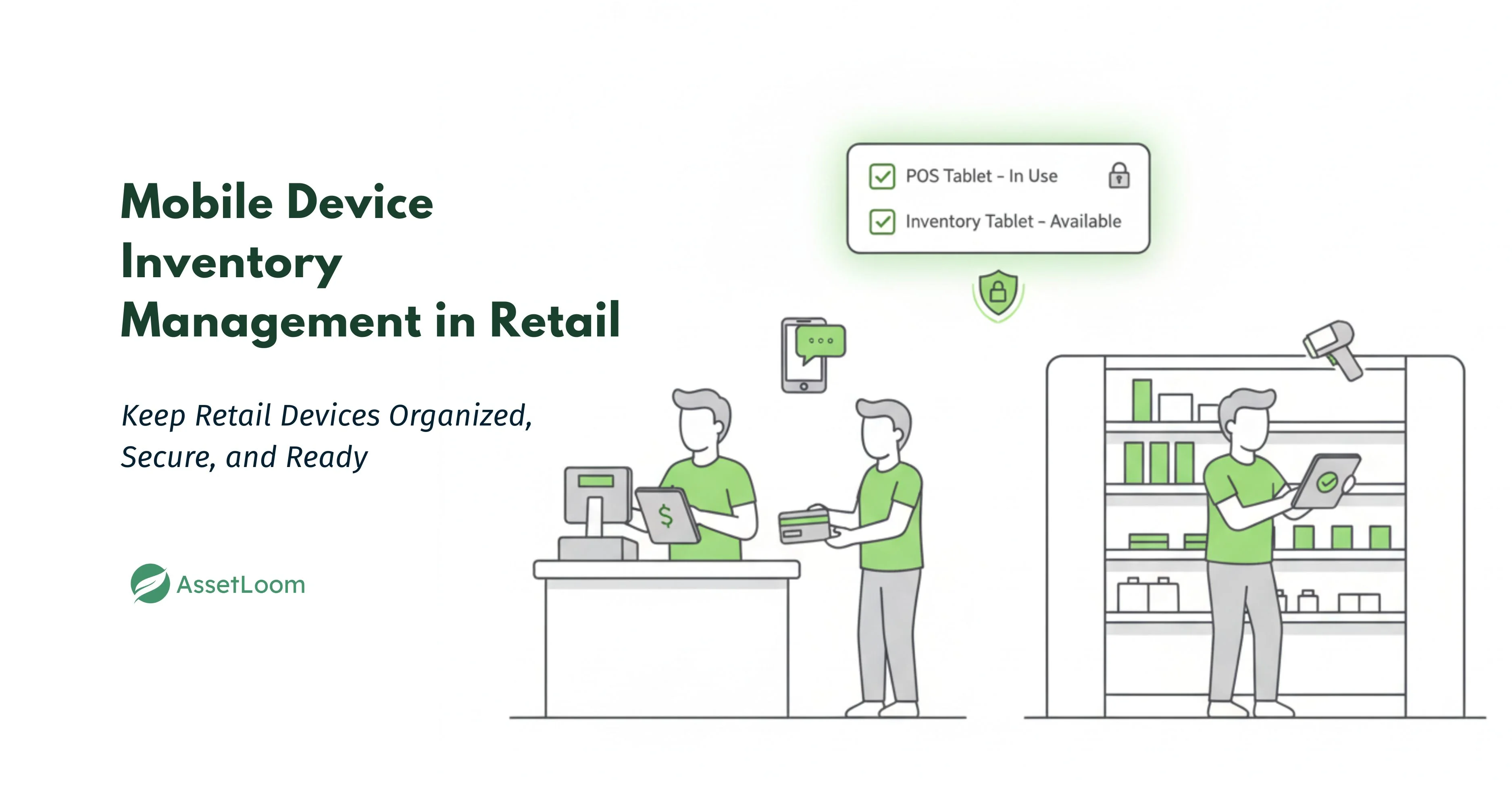

Mobile Device Inventory Management in Retail and Warehouses

Retail and warehouse operations depend heavily on mobile devices, but the way they use them is slightly different. Breaking it down helps show why device management is so important for both.

Retail Stores

Mobile devices are now part of almost every retail operation. From checkout counters to stock checks, they help staff work faster and improve the customer experience.

Common devices in retail

- Point-of-sale (POS) tablets

- Smartphones for staff communication

- Mobile checkout systems

- Tablets for quick inventory checks

Challenges in retail

- Devices are passed between employees, making it easy to lose track

- Tablets and phones can get damaged during busy hours

- Check out delays when devices are unavailable or not working

Benefits of management in retail

- Faster and more reliable checkouts during peak hours

- Clear accountability when devices are shared across shifts

- Lower costs from fewer replacements and repairs

Warehouses

In warehouses, mobile devices are mostly used behind the scenes, but they play a critical role in keeping products moving.

Common devices in warehouses

- Barcode scanners

- Handheld terminals for inventory updates

- Tablets for shipment tracking

- Rugged smartphones for communication

Challenges in warehouses

- Devices are often left behind on shelves or forklifts

- Downtime when scanners fail during stock counts

- Lack of visibility on how many working devices are available

Benefits of management in warehouses

- Up-to-date visibility on device location and status

- Reduced downtime during shipping and receiving

- Longer device lifecycles with timely maintenance

How Can Retailers Improve Mobile Device Inventory Management?

Retailers can strengthen their mobile device inventory management by focusing on a few practical steps. These best practices make it easier to keep devices organized, secure, and ready for use.

Use centralized inventory tracking

A single system that records all devices gives managers a clear view of what’s available. This reduces confusion when devices are shared across different teams or shifts.

Apply clear labeling and tagging

Adding barcodes, QR codes, or RFID tags to devices makes them easier to identify and track.

Benefits of labeling

- Quicker check-in and check-out process

- Fewer misplaced devices

- Faster audits when reviewing inventory

Set up check-in and check-out policies

When employees borrow devices at the start of a shift and return them at the end, accountability improves.

Tips for better check-in/out

- Assign devices to specific employees or departments

- Keep digital records of who used what

- Review logs regularly to spot patterns

Automate updates and maintenance

Inventory systems can send alerts for software updates, warranty expirations, or routine checks. This helps prevent device failures during peak business hours.

Train employees on device responsibility

Staff should understand how important mobile devices are to daily operations. Simple training on handling, returning, and reporting issues can make a big difference.

Conclusion

Mobile device inventory management is more than just a record-keeping task. For retail stores and warehouses, it directly affects productivity, costs, and the customer experience. When devices are tracked, maintained, and used responsibly, businesses spend less on replacements and avoid unexpected downtime. Over time, this creates smoother operations and healthier profit margins.

Key takeaways for retailers and warehouses

- Mobile devices are essential tools in both customer-facing and back-end operations

- A structured system prevents losses and keeps devices reliable

- Best practices like labeling, check-in/out policies, and automation improve accountability

- Training staff ensures that devices are cared for and always available when needed

By treating mobile device inventory management as a core part of IT inventory management, retailers and warehouses can keep daily work efficient and reduce unnecessary costs.

FAQs

What is mobile device inventory management?

It is the process of tracking, organizing, and maintaining mobile devices like tablets, smartphones, and scanners used in retail stores and warehouses.

Why is mobile device inventory management important in retail?

Retail stores rely on devices for checkout, stock checks, and communication. Managing them properly helps prevent losses, reduce downtime, and keep customer service smooth.

How does inventory management help warehouses?

In warehouses, devices such as barcode scanners and tablets are used for stock movement and shipping. Inventory management ensures these tools are always available and reduces the risk of delays.

Can mobile device inventory management save costs?

Yes. By reducing losses, extending device lifecycles, and avoiding unnecessary purchases, businesses spend less on replacements and repairs.

What tools are used for mobile device inventory management?

Many businesses use IT inventory management software, barcode or QR code labels, and cloud-based systems to track devices in real time.

How often should devices be checked?

Devices should be checked daily if they are shared across shifts. Regular audits (monthly or quarterly) help ensure all devices are accounted for and in good condition.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox