QR, Barcode, or RFID: What’s the Best Fix for IT Inventory Tracking?

Discover the best IT inventory tracking solution in 2025: QR codes, barcodes, or RFID? Compare costs, speed, and scalability to fix your IT inventory tracking concerns.

Picture this: you’re an IT manager staring at a spreadsheet that claims you have 500 laptops, but last week’s audit only found 480. Somewhere, 20 laptops are playing hide-and-seek, and your boss is asking why you’re over budget on software licenses. Sound familiar?

With remote workers scattered across the globe, cloud services multiplying, and IoT devices popping up everywhere, IT inventory tracking is a high-stakes puzzle. An unsteady inventory isn’t just annoying, it can lead to security breaches, compliance fines, or a $100,000 bill for unused cloud resources. Fortunately, three technologies: QR codes, barcodes, and RFID, are here to save the day. But which one is the best for fixing your IT inventory tracking?

In this article, we’ll break down what QR codes, barcodes, and RFID are in the context of IT inventory management, weigh their strengths and weaknesses.

Spoiler: there’s no one-size-fits-all answer, but by the end, you’ll have a clear path forward.

What Are QR Codes, Barcodes, and RFID?

Before we dive into the showdown, let’s get to know the players. Each of these technologies is used to tag and track IT assets like laptops, servers, monitors, or even software licenses tied to specific devices. Here’s a quick introduction on what they are and how they fit into IT inventory management.

What are QR Codes?

QR (Quick Response) codes are those square, black-and-white patterns you’ve scanned to pull up a website or pay for coffee. In IT inventory management, QR codes are printed on stickers or labels and attached to assets like desktops, routers, or even server racks. Each QR code encodes data, such as an asset ID, serial number, or location, that can be scanned using a smartphone or dedicated scanner. Scanning pulls up the asset’s details in your inventory management system, letting you update records on the spot.

QR codes in AssetLoom

For example, an IT tech might scan a QR code on a monitor to log its assignment to a new employee or confirm its location during an audit. QR codes are cheap, easy to generate, and can store more data than traditional barcodes, making them a popular choice for organizations looking to streamline tracking without breaking the bank.

What are Barcodes?

Barcodes are the classic choice for inventory tracking. Those familiar black-and-white stripes you see on everything from cereal boxes to library books. In IT inventory management, barcodes are printed on labels and stuck to assets like keyboards, printers, or hard drives. Each barcode represents a unique identifier (like an asset number) that links to a database entry. Scanning with a barcode reader retrieves the asset’s details, allowing IT teams to update inventory records, track maintenance, or verify ownership.

Barcodes have been around forever (well, since the 1970s), and they’re still widely used because they’re dirt cheap and reliable for simple tracking. For instance, a data center might use barcodes to catalog thousands of servers, with technicians scanning each one during routine checks. However, barcodes hold less data than QR codes and require line-of-sight scanning, which can slow things down.

Learn more: Barcode Inventory Tracking System.

What is RFID?

RFID (Radio Frequency Identification) is the high-tech contender. Unlike QR codes or barcodes, RFID uses radio waves to track assets wirelessly. An RFID system consists of tags (small chips with antennas) attached to assets, readers that detect the tags, and software that processes the data. In IT inventory management, RFID tags are placed on assets like laptops, network switches, or even USB drives. Readers, either handheld or fixed (like at a doorway), pick up the tags’ signals, identifying assets without direct contact.

![]()

For example, an IT team could walk through an office with a handheld RFID reader, instantly logging every tagged asset in the room, or set up fixed readers at exits to track devices leaving the building. RFID’s big selling point is speed and automation—it can read multiple tags at once, even through walls or bags, making it ideal for high-volume or dynamic environments. But it comes with a higher price tag and some setup complexity.

Why IT Inventory Tracking Needs a Fix

Before we compare these technologies, let’s talk about why IT inventory tracking is such a mess in the first place. An unsteady inventory can cost you big time. Think $100,000 in unused software licenses, a data breach from an unpatched device, or a failed HIPAA audit because you couldn’t account for every tablet. Here are the key challenges driving the need for better tracking:

- Human Error: Manual logging (like updating spreadsheets) leads to typos or forgotten entries. A mistyped serial number can mean a server goes untracked, risking security gaps.

- Distributed Workforces: Remote workers in 2025 are using devices across cities or countries, making it tough to know where assets are or if they’re secure.

- Shadow IT: Unapproved devices or apps (like a personal laptop accessing company data) create blind spots in your inventory.

- Rapid Tech Changes: New hardware, cloud resources, and IoT devices pop up daily, outpacing manual tracking.

- Compliance Pressures: Regulations like GDPR or CCPA demand precise asset records, and a single missing device can trigger fines.

QR codes, barcodes, and RFID aim to solve these issues by making tracking faster, more accurate, and less reliant on human effort. But how do they stack up? Let’s break it down.

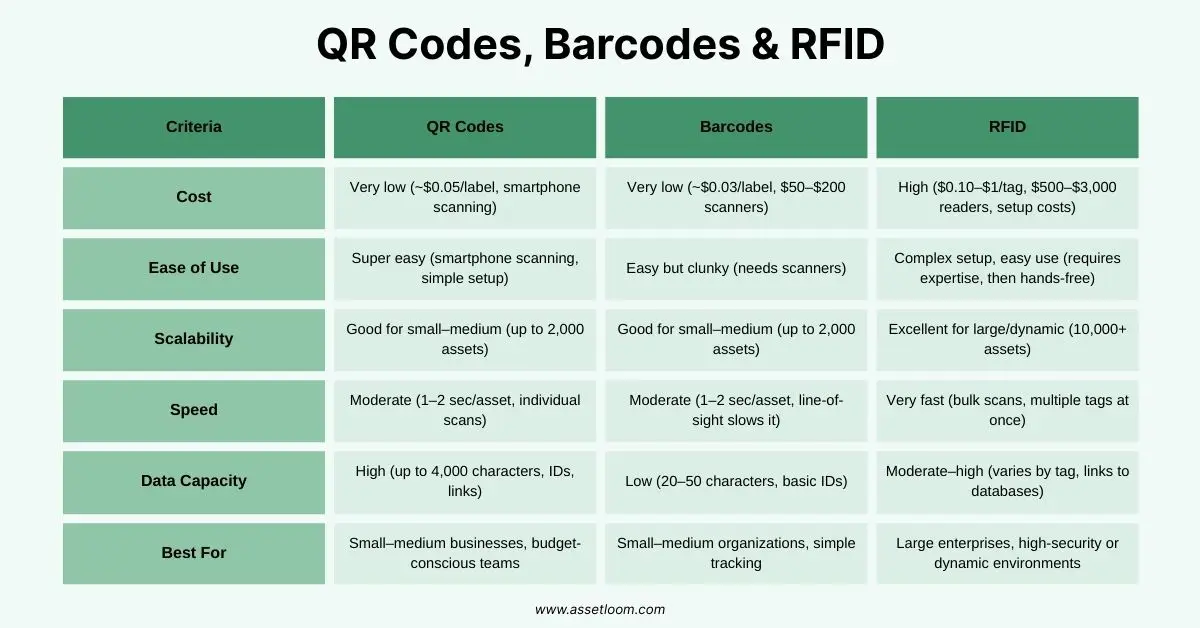

QR Codes vs. Barcodes vs. RFID: The Comparison

Each technology has its strengths, weaknesses, and ideal use cases for IT inventory management. We’ll compare them across key factors: cost, ease of use, scalability, speed, data capacity, and security. Real-world examples will show how they perform in practice.

1. Budget Matters

- QR Codes: Dirt cheap. Printing QR code labels costs pennies, and you can scan them with any smartphone, no special hardware needed. A small business with 100 assets might spend under $50 on labels and use free QR code generators.

- Barcodes: Also budget-friendly. Barcode labels are slightly cheaper than QR codes, and basic scanners cost $50–$200. However, you might need multiple scanners for a large team.

- RFID: The priciest option. RFID tags cost $0.10–$1 each, readers range from $500 to $2,000, and setup (like integrating with software) can hit thousands.

Winner: QR codes or barcodes for tight budgets; RFID if you can afford the investment.

2. Ease of Use

- QR Codes: Super user-friendly. Anyone with a smartphone can scan a QR code, and generating labels is as easy as using an online tool. Integration with inventory software is straightforward.

- Barcodes: Easy but less flexible. You need dedicated scanners, and line-of-sight scanning means aligning the reader just right, which can be finicky in cramped server rooms.

- RFID: Steeper learning curve. Setting up readers and integrating with software requires tech expertise, but once running, it’s hands-off.

Winner: QR codes for simplicity; RFID once setup is done.

3. Scalability: Can It Grow with You?

- QR Codes: Scales well for small to medium setups (up to a few thousand assets). Scanning each asset individually can get time-consuming for massive inventories.

- Barcodes: Similar to QR codes, great for small to medium environments but slows down with scale. Line-of-sight scanning limits efficiency in large setups.

- RFID: Built for scale. It can read hundreds of tags simultaneously, perfect for large or dynamic environments.

Winner: RFID for large-scale or complex environments; QR/barcodes for smaller setups.

4. Speed: How Fast Can You Track?

- QR Codes: Moderately fast. Scanning is quick (1–2 seconds per asset), but each item must be scanned individually, which adds up.

- Barcodes: Similar to QR codes, with slightly slower scanning due to line-of-sight requirements.

- RFID: Lightning-fast. It reads multiple tags at once, even without line-of-sight, ideal for bulk tracking.

Winner: RFID, hands-down.

5. Data Capacity: How Much Can It Hold?

- QR Codes: High capacity. They can store up to 4,000 characters—enough for asset IDs, locations, or even URLs linking to detailed records.

- Barcodes: Limited capacity. Most hold 20–50 characters, enough for basic IDs but not much else.

- RFID: Moderate to high, depending on the tag. Active RFID tags can store detailed data, but passive tags (more common in IT) are closer to barcodes.

Winner: QR codes for data-rich needs; RFID for specific use cases.

Which Fits Your Needs?

To make the choice clearer, let’s look at how these technologies play out in specific IT inventory scenarios.

- Small Business (100–500 assets): A startup with 200 devices (laptops, monitors) needs a low-cost solution. QR codes shine here. cheap labels, smartphone scanning, and easy integration with free inventory apps. The startup tracks assets during onboarding and audits, spending under $100.

- Mid-Sized Organization (1,000–5,000 assets): A college with 2,000 classroom devices wants reliability without complexity. Barcodes work well on this. Affordable labels and scanners handle the volume, though audits take a few days. QR codes are a close second if more data storage is needed.

- Large Enterprise (10,000+ assets): A global tech firm with 50,000 assets across data centers and offices needs speed and automation. RFID is the clear winner. Bulk scanning and real-time tracking cut audit times and catch shadow IT, justifying the $50,000 investment.

Getting Started with Better IT Inventory Tracking

Ready to fix your IT inventory tracking? Here’s how to choose and implement the right technology:

- Assess Your Needs: Consider your asset volume, budget, and priorities (speed, security, compliance). A small team might lean toward QR codes; a data center might need RFID.

- Test a Pilot: Start with one department or asset type. For example, try QR codes on laptops or RFID in a server room to gauge effectiveness.

- Integrate with ITAM Software: Pair your tracking tech with a modern IT asset management platform (like ServiceNow ITAM or Lansweeper) for real-time updates and analytics.

- Train Your Team: Ensure IT staff know how to scan, update records, and troubleshoot. QR and barcode training takes hours; RFID might need a few days.

- Monitor and Refine: Use data from scans to spot gaps (like shadow IT) and optimize processes, like automating audit schedules.

To Conclude: The Right Tool for the Job

IT inventory tracking doesn’t have to be a headache. QR codes, barcodes, and RFID each offer unique strengths to tackle the chaos of 2025’s IT environments. QR codes are the budget-friendly, data-rich choice for small to medium setups, perfect for startups or schools. Barcodes are the reliable, no-frills option for organizations needing simple tracking without complexity. RFID is the high-powered solution for large, dynamic, or security-conscious environments, delivering speed and automation at a premium.

The best choice depends on your organization’s size, budget, and goals. By picking the right technology and pairing it with modern ITAM tools, like automated discovery and AI-powered analytics, you can transform your inventory from a liability into a superpower, ensuring every asset is tracked, secure, and accounted for. So, what’s it going to be: QR, barcode, or RFID?

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom, right in your inbox.