Using QR Codes or Traditional Asset Tags: What’s Best for Inventory Accuracy?

Learn the difference between QR codes and traditional asset tags for inventory tracking. Compare pros, cons, and use cases to choose the right method for your business.

Inventory accuracy directly impacts operations, customer service, and compliance. Errors lead to lost items, delays, and failed audits all of which cost time and money.

Two common tracking methods are QR codes and traditional asset tags (like barcodes or serial numbers). Both are effective, but they serve different needs depending on your systems, workflows, and compliance requirements.

This guide compares QR codes and asset tags based on accuracy, usability, scalability, and compliance, so you can choose what fits your business best; whether you're managing tools, equipment, or inventory at scale.

What Are QR Codes and Traditional Asset Tags?

1. QR Codes

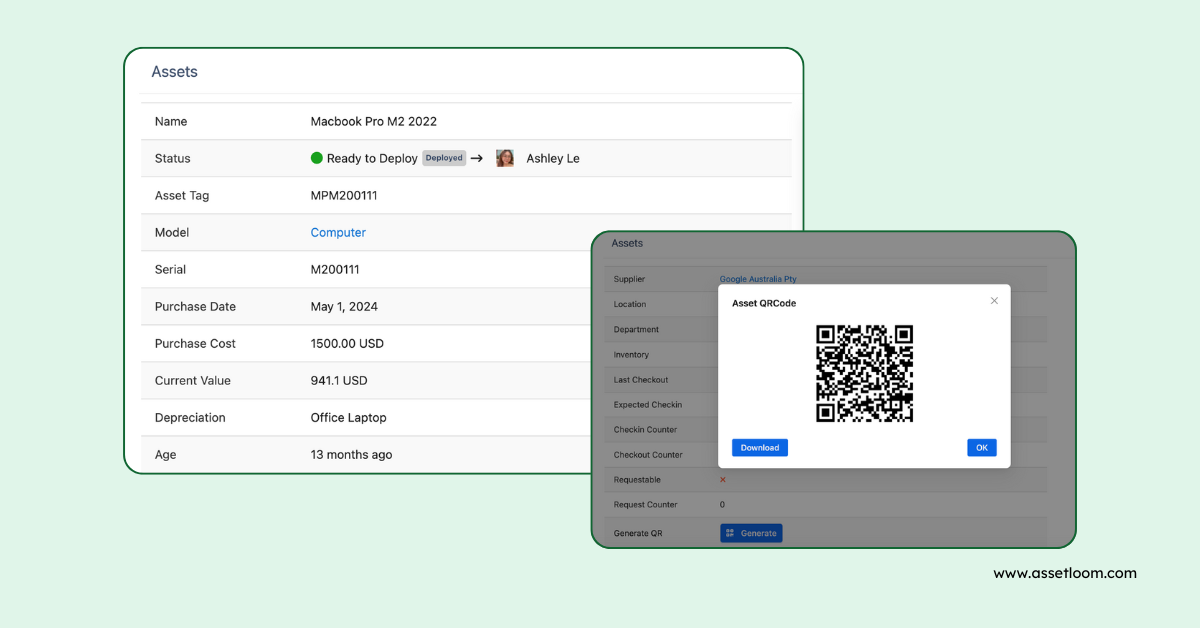

QR (Quick Response) codes are two-dimensional barcodes that store more information than traditional 1D barcodes. They can hold asset IDs, location data, timestamps, URLs, or other metadata. QR codes can be scanned using smartphones, tablets, or QR scanners, making them ideal for mobile teams and cloud-based systems.

Common uses:

- Tracking tools and equipment in construction or field service.

- Managing warehouse inventory with mobile devices.

- Linking assets to service records, inspection logs, or digital manuals.

Example: A field technician scans a QR code on a power drill with their phone to log maintenance, view usage history, and mark the item as checked out.

2. Traditional Asset Tags

Traditional asset tags usually feature a 1D barcode or a serial number printed on a label or plate. These tags link to records in an internal system and require a barcode scanner or compatible software to read. They're widely used in environments where assets are stable and processes are well-established.

Common uses:

- Fixed asset tracking in offices (laptops, printers, monitors)

- Equipment tagging in manufacturing and finance

- Barcode-based inventory control in retail or logistics

Example: During an annual audit, a company uses barcode scanners to confirm the location and status of all laptops by scanning asset tags and reconciling them against the internal asset register.

What is asset tags and why you need them?What About RFID or NFC? (Addition)

RFID (Radio-Frequency Identification) and NFC (Near Field Communication) are advanced tagging methods that don’t require direct line-of-sight scanning. They’re used in high-volume or automated environments where hands-free tracking is needed — such as large warehouses, hospitals, or industrial supply chains.

While powerful, RFID/NFC systems are more expensive to implement and are not always necessary for most small or mid-sized businesses. In this guide, we’ll focus on QR codes and traditional asset tags, as they remain the most accessible and widely adopted tracking methods today.

Traditional asset tags vs RFIDWhat’s the Difference Between QR Codes and Asset Tags?

Choosing between QR codes and traditional asset tags starts with understanding their strengths and trade-offs. Below is a breakdown to help you see how each method fits into real-world inventory environments, especially when it comes to usability, accuracy, scalability, and long-term value.

1. Pros and Cons of QR Codes and Traditional Asset Tags

QR Codes

Pros:

- Easy to scan with mobile devices: No need for special hardware. Smartphones or tablets can scan QR codes instantly in the field or warehouse.

- Supports real-time updates and cloud syncing: Once scanned, a QR code can trigger live updates in your inventory system, improving visibility and reducing data lag.

- Stores more than just an ID: You can embed asset details, location data, URLs, service records, or inspection notes within or linked from the code.

- Scales well with growth: Suitable for companies with expanding operations, multiple locations, or mobile teams who need fast, consistent access to data.

- Compatible with modern platforms: Systems like AssetLoom support QR code tracking out of the box, making integration simple.

Cons:

- Requires mobile devices or scanners: Teams need access to smartphones or tablets with camera functionality, plus training on how to use them correctly.

- Code quality matters: Damaged, dirty, or low-contrast labels can be hard to scan, especially in rugged environments.

- Relies on infrastructure: To get the most from QR codes, you’ll need internet access (or offline sync capabilities) and a system to store or process the data.

Traditional Asset Tags

Pros:

- Simple and familiar: Most teams are used to barcodes or serial numbers. They can be logged manually or scanned with basic equipment.

- Durable and reliable: Engraved or metal asset tags work well in harsh environments where printed labels may wear down.

- Low setup cost: You don’t need mobile apps or cloud tools to get started. A spreadsheet and barcode scanner might be all you need.

- Ideal for fixed assets: For items that stay in one place like office equipment, manufacturing tools, or infrastructure; traditional tags are often enough.

Cons:

- Limited data capacity: Traditional tags typically store just an ID number. You have to look up the rest of the info elsewhere.

- Slower updates and higher error risk: Manual entry or disconnected systems can lead to delays, missed updates, or duplicated records.

- Harder to scale: As operations grow, tracking with basic tags and spreadsheets becomes harder to manage without automation.

- Not built for real-time visibility: These tags work best when you don’t need instant updates or integration with other tools.

2. QR Codes vs. Traditional Asset Tags: Feature Comparison

To help you quickly assess which method fits your business, here’s a side-by-side look at how QR codes and traditional asset tags perform across key criteria.

| Feature | QR Codes | Traditional Asset Tags |

|---|---|---|

| Ease of Use | Scannable with smartphones or tablets | Simple to apply and scan with a basic barcode reader |

| Data Capacity | High – can store links, metadata, timestamps | Low – usually limited to an ID or serial number |

| Accuracy | High, especially when integrated with live systems | Depends on manual processes; more prone to user error |

| Durability | Good with proper materials, but can wear or smudge | Excellent – metal or engraved tags last longer in harsh environments |

| Setup Requirements | Requires generating QR codes, assigning to assets, and training | Minimal – print or engrave tags and log them in a system |

| Scalability | Scales well with cloud-based tools and mobile workflows | Becomes harder to manage as inventory volume increases |

| Real-Time Updates | Yes – supports live syncing and audit trails | No – updates often happen in batches or during audits |

| Tech Requirements | Needs mobile devices and an inventory system (e.g. AssetLoom) | Works with spreadsheets or standalone scanners |

| Best Use Case | Mobile assets, growing teams, dynamic workflows | Fixed assets, small-scale or low-tech environments |

How Can You Choose the Right Inventory Tracking Method for Your Business?

Before picking between QR codes or traditional asset tags, take a step back and look at how your business actually works. The right choice starts with understanding your assets, people, and goals.

Here’s a step by step guide to help you clarify what you need and avoid choosing a system that doesn’t fit.

![]()

Step 1: Identify What You’re Tracking

- Are you tracking equipment, inventory, tools, or fixed assets?

- Are these items stationary (like office desks or factory machines) or mobile (like tools, products, or field gear)?

Advice: Use QR codes for mobile or rotating assets that need regular updates. Use traditional tags for long term, fixed equipment that rarely moves.

Step 2: Understand Where Your Assets Live

- Are your assets spread across multiple locations or just in one building?

- Are they used indoors, outdoors, or in rugged environments?

- Do you need to track assets in real time, or is periodic auditing enough?

Advice: Use QR codes for multi-location or fast-moving environments. Use engraved or metal tags in harsh conditions where printed codes may wear down.

Step 3: Look at Your Team’s Tools and Skills

- Do your staff have access to smartphones, tablets, or scanners?

- Are they comfortable using digital tools for logging and tracking?

- Will you need to train them on a new process?

Advice: If your team already uses mobile devices, QR codes can streamline tracking. If your team prefers manual systems or has no mobile access, traditional tags may be simpler.

Step 4: Consider How Much Data You Need to Track

- Do you just need a simple ID, or do you want to store maintenance logs, locations, or linked documents?

- Are you tracking compliance, inspections, or certifications?

Advice: Use QR codes if you want to store or link extra information to each item. Use basic tags if all you need is a unique ID for inventory or auditing.

Step 5: Think About Growth and Scale

- Are you planning to expand, add locations, or digitize more processes?

- Will you need to generate reports, share data with other systems, or integrate with software?

Advice: Use QR codes if you're thinking about scaling, automating, or integrating. Traditional tags can still work if you expect things to stay simple and local.

Step 6: Define Your Budget and Timeframe

- Do you need a solution that’s fast to set up, or are you planning for a long-term system?

- What’s your budget for equipment, labels, and software?

Advice: Traditional tags are fast and low-cost to implement. QR codes may require more setup, but they offer better long-term efficiency if paired with the right system.

Optional: Use Both Methods Where It Makes Sense

Some businesses do both and that’s perfectly fine.

- Use QR codes for fast-moving inventory, field equipment, or items that need frequent updates.

- Use traditional asset tags for office equipment, permanent fixtures, or legacy assets.

If your inventory system supports both (like AssetLoom), you don’t have to choose one over the other.

Final Thoughts

Choosing the right tracking method isn’t just about technology; it’s about how your team works, how your assets move, and what kind of control you need.

Start simple:

- Review how your current tracking process works (or doesn’t)

- Identify which assets move, which stay put, and who interacts with them

- Test one method on a small group of assets before scaling up

Whether you go with QR codes, traditional asset tags, or a mix of both, the goal is the same: more accurate inventory with less friction.

And if you’re using a system like AssetLoom, you can use both methods side by side tracking what you need, the way that works best for your team.

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox