Traditional Asset Tags for Equipment Tracking vs. RFID: Which Is Better?

Discover whether asset tags for equipment or RFID tags suit your business. Compare costs, scalability, and more with a checklist.

Imagine you’re managing a warehouse full of heavy machinery or a hospital with hundreds of medical devices. Every piece of equipment needs to be tracked—where it is, when it was last serviced, and whether it’s ready for use. Losing track of even one item could mean costly downtime or compliance issues. This is where asset tags for equipment come into play. Basically, asset tags are identification labels attached to your equipment so you can track their information through just quick scan.

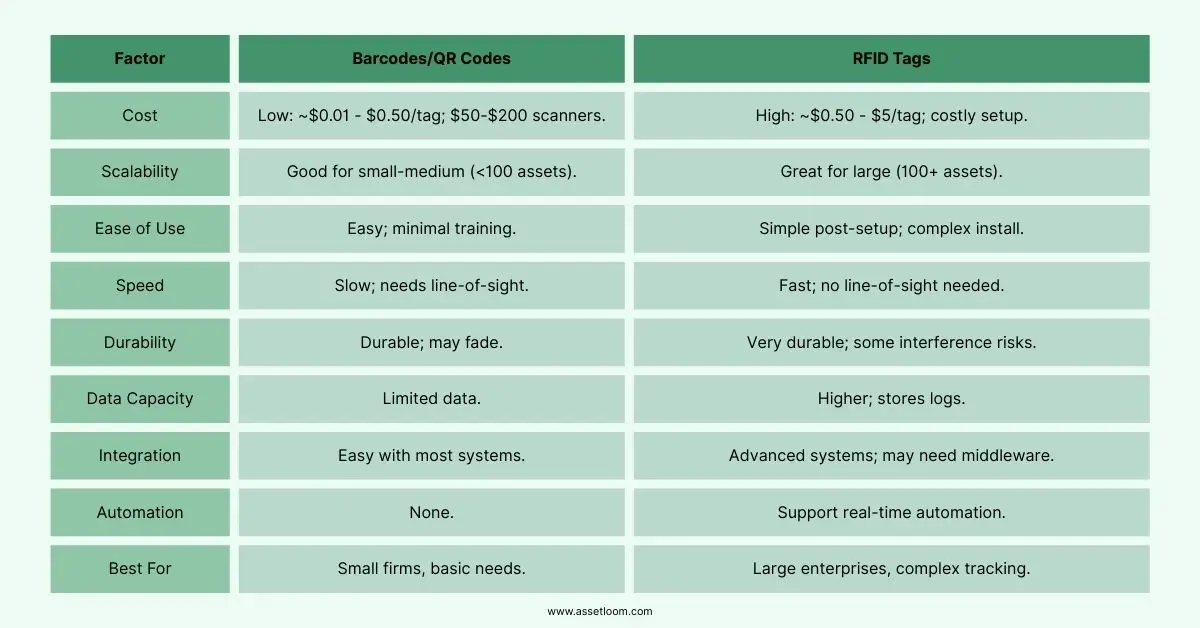

But here’s the question: Should you stick with traditional asset tags, like barcodes or QR codes, or invest in cutting-edge RFID technology? Both have their strengths, but choosing the right one depends on your business’s needs, budget, and goals.

In this article, we’ll dive into a head-to-head comparison of traditional asset tags for equipment (barcodes and QR codes) versus RFID tags. We’ll explore their costs, scalability, ease of use, and how they integrate with asset management systems. By the end, you’ll have a clear decision-making checklist to help you pick the best solution for your business, whether you’re a small startup or a large enterprise.

What Are Asset Tags for Equipment?

Before we compare the two technologies, let’s clarify what asset tags are. Asset tags are labels or tags attached to physical assets like machinery, tools, medical devices, etc., to track their location, status, or maintenance history. They typically include a unique identifier, like a serial number.

Traditional asset tags often use barcodes or QR codes, which are scanned optically using a handheld device or smartphone. RFID (Radio Frequency Identification) tags, on the other hand, use radio waves to transmit data wirelessly, often without needing a direct line of sight. Both options serve the same purpose: tracking equipment, but their approaches and capabilities differ significantly.

Related article: QR, Barcode, or RFID: What’s the Best Fix for IT Inventory Tracking?

Traditional Asset Tags: Barcodes and QR Codes

How They Work

Picture a barcode on a piece of construction equipment. You grab a scanner, point it at the barcode, and instantly pull up details about the asset in your inventory system. QR codes work similarly but can store more data and are easily scanned with a smartphone camera. These asset tags for equipment are simple, affordable, and widely used across industries like manufacturing, healthcare, and logistics.

Pros of Traditional Asset Tags

- Cost-Effective: Barcodes and QR codes are inexpensive to produce. You can print durable labels for as little as a few cents each, making them ideal for businesses with tight budgets.

- Ease of Use: Scanning a barcode or QR code is straightforward. Most employees can learn to use a scanner or smartphone app in minutes.

- Universal Compatibility: Barcode and QR code systems integrate seamlessly with most asset management software.

- Customization: You can design asset tags for equipment to include your logo, color-coding, or specific data fields, all while keeping costs low.

Cons of Traditional Asset Tags

- Line-of-Sight Requirement: You need to physically see and scan each tag, which can be time-consuming in large facilities or when equipment is stacked tightly.

- Manual Process: Scanning one tag at a time slows down inventory counts, especially for businesses with thousands of assets.

- Durability Concerns: While modern asset tags are built to last, barcodes and QR codes can become unreadable if scratched, faded, or exposed to harsh conditions over time.

- Limited Data Capacity: Barcodes store minimal data, and even QR codes have limits compared to other technologies.

Traditional asset tags for equipment shine in smaller operations or industries where assets don’t move frequently. For example, a small construction firm might use barcode tags to track tools stored in a single yard, finding the low cost and simplicity perfect for their needs.

RFID Tags: The High-Tech Alternative

How They Work

Now, imagine walking into a warehouse with an RFID reader in hand. Without even seeing the equipment, the reader picks up signals from RFID tags attached to every asset within a 20-foot radius. Each tag contains a tiny chip and antenna that transmits data wirelessly to your system.

RFID tags come in two types: passive (powered by the reader’s signal, no battery) and active (battery-powered for longer range). Passive tags are more common for equipment tracking due to their lower cost and maintenance.

Pros of RFID Tags

- Speed and Efficiency: RFID readers can scan multiple tags simultaneously, even through walls or containers, making inventory counts lightning-fast.

- No Line-of-Sight Needed: You don’t need to see the tag, which is a game-changer for tracking equipment in cluttered or hard-to-reach areas.

- Higher Data Capacity: RFID tags can store more information, like maintenance logs or usage history, directly on the tag.

- Automation Potential: RFID systems can integrate with automated processes, such as triggering alerts when equipment leaves a designated area.

- Durability: Many RFID tags are built for extreme conditions, with rugged casings that resist water, chemicals, and heat.

Cons of RFID Tags

- Higher Costs: RFID tags are pricier than barcode labels, often costing $0.50 to $5 each, depending on the type. Readers and infrastructure (like antennas) also add to the upfront investment.

- Complex Setup: Implementing an RFID system requires technical expertise to install readers, configure software, and ensure compatibility with existing systems.

- Interference Issues: Metal surfaces or liquids can disrupt RFID signals, which may require specialized tags or reader adjustments for equipment in certain environments.

- Scalability Challenges for Small Businesses: The initial cost and complexity can be overkill for businesses with only a few assets to track.

RFID tags are a powerhouse for large enterprises with complex operations. For instance, a hospital managing thousands of medical devices across multiple floors can use RFID to track equipment in real-time, reducing search times and improving patient care.

Comparing Key Factors: Cost, Scalability, and Ease of Use

Cost

- Traditional Asset Tags: The clear winner for budget-conscious businesses. Printing asset tags for equipment with barcodes or QR codes is dirt-cheap, and basic scanners cost $50-$200. Software integration is often free or low-cost if you’re using existing systems.

- RFID Tags: The upfront cost is higher, with tags, readers, and installation potentially running into thousands of dollars. However, the long-term savings from faster inventory counts and reduced asset loss can offset this for large operations.

➡️ Small businesses or those with limited budgets will lean toward traditional asset tags for equipment. Large enterprises with high-value assets or frequent inventory needs may find RFID’s higher cost worthwhile.

Scalability

- Traditional Asset Tags: These work well for small to medium-sized businesses but can become cumbersome as asset counts grow. Manually scanning thousands of tags during an audit is a slow, error-prone process.

- RFID Tags: RFID scales beautifully for large operations. The ability to scan multiple tags at once and integrate with automated systems makes it ideal for enterprises with extensive equipment fleets or complex supply chains.

➡️ RFID takes the lead for scalability, especially for businesses planning to grow or those already managing large inventories.

Ease of Use

- Traditional Asset Tags: Incredibly user-friendly. Employees need minimal training to scan barcodes or QR codes, and the technology is familiar to most.

- RFID Tags: While RFID readers are simple to use, setting up the system requires technical know-how. Once installed, the scanning process is effortless, but troubleshooting interference or software issues may need IT support.

➡️ Traditional asset tags for equipment are easier to implement and use out of the box, making them better for non-technical teams or smaller setups.

Integration with Asset Management Systems

Both technologies integrate with asset management systems, but the experience differs.

- Traditional Asset Tags: Barcodes and QR codes are compatible with virtually every asset management platform, from basic tools like Excel to enterprise-grade IT asset tracking software like AssetLoom or ServiceNow. Scanning a tag pulls up the asset’s record, where you can update details like location or maintenance status. The process is manual but reliable, and many systems offer mobile apps for on-the-go scanning.

- RFID Tags: RFID systems integrate with advanced asset management software, often enabling real-time tracking and automation. For example, RFID can trigger alerts if equipment leaves a facility or automatically update inventory during a scan. However, integration may require custom software or middleware, adding to the setup complexity and cost.

➡️ Traditional asset tags for equipment are easier to integrate with basic or existing systems, while RFID offers more robust, automated integration for tech-savvy enterprises.

Checklist to Choose the Right Asset Tags for Equipment

Ready to decide between traditional asset tags for equipment and RFID tags? Use this checklist to guide your choice:

✅ What’s Your Budget?

- If you’re working with limited funds, start with barcode or QR code tags. They’re affordable and effective for basic tracking.

- If you can invest upfront for long-term savings, consider RFID, especially for high-value or frequently moved equipment.

✅ How Many Assets Are You Tracking?

- For fewer than 100 assets, traditional tags are usually sufficient and cost-effective.

- For hundreds or thousands of assets, RFID’s speed and scalability make it a better fit.

✅ What’s Your Environment Like?

- If your equipment is in harsh conditions (e.g., outdoor construction sites), ensure your tags—barcode or RFID—are durable and suited for the environment.

- If metal or liquids are prevalent, test RFID tags for interference or opt for specialized models.

✅ How Fast Do You Need Inventory Counts?

- If occasional, manual audits are fine, traditional asset tags for equipment will do the job.

- If you need real-time or frequent inventory updates, RFID’s speed is unmatched.

✅ What’s Your Team’s Tech Comfort Level?

- For teams with limited technical skills, barcodes or QR codes are simpler to implement and use.

- If you have IT support or are comfortable with tech setups, RFID’s complexity won’t be a barrier.

✅ Do You Need Automation?

- If you want basic tracking, traditional tags are enough.

- If you’re aiming for automated alerts, geofencing, or real-time data, RFID is the way to go.

✅ What Systems Are You Using?

- Check if your asset management software supports RFID or if you’ll need additional tools.

- Ensure your current system can handle barcode/QR code data or if upgrades are needed.

Final Thoughts: Which Asset Tag is Better for Your Business?

Choosing between traditional asset tags for equipment and RFID tags isn’t about finding a one-size-fits-all solution, it’s about aligning the technology with your business’s unique needs. If you’re a small business or just starting with asset tracking, barcode or QR code tags offer a low-cost, user-friendly way to get organized. They’re reliable, widely compatible, and perfect for straightforward tracking.

On the other hand, if you’re managing a large operation with hundreds of assets, frequent inventory counts, or a need for real-time data, RFID tags are worth the investment. Their speed, automation potential, and scalability can transform how you track equipment, saving time and reducing errors.

Take a moment to assess your budget, asset volume, and operational goals using the checklist above. Whether you choose the simplicity of traditional asset tags for equipment or the high-tech efficiency of RFID, you’ll be taking a big step toward better asset tracking.

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox