Breaking Down Equipment Lifecycle Management: 6 Core Processes

Equipment Lifecycle Management: Explore the 6 key processes that optimize asset value, reduce costs, and support long-term business success.

Managing equipment involves more than just buying it and using it until it wears out. Each item goes through a full cycle that includes planning, purchasing, setup, daily use, upkeep, and finally, disposal. When every stage is handled with care, it's easier to avoid breakdowns, reduce waste, and make smarter decisions about replacements.

This post explains the six core processes in equipment lifecycle management. These steps apply to many types of equipment, such as laptops, factory machines, or tools used in the field. The aim is to give a clear look at what happens during each phase so teams can stay on top of their assets from start to finish.

Overview of the 6 Core Processes

Managing equipment across its entire lifecycle involves six key processes. Each one helps ensure that assets are planned for, used efficiently, maintained properly, and retired responsibly.

| Process | Description |

|---|---|

| Planning | Assess equipment needs, forecast future use, and set specifications based on goals and budget. |

| Acquisition | Obtain equipment through purchase, lease, or other methods; evaluate suppliers and negotiate terms. |

| Installation | Set up the equipment, integrate it with existing systems, and test for readiness. |

| Operation | Use equipment in day-to-day work, train users, and monitor performance. |

| Maintenance | Carry out regular servicing and repairs to extend lifespan and avoid downtime. |

| Disposal | Safely decommission and dispose of equipment through resale, recycling, or other approved methods. |

Each of these processes contributes to better control, reduced risk, and longer asset life. In the next sections, we’ll look at them one by one in more detail.

What Is IT Asset Lifecycle Management?

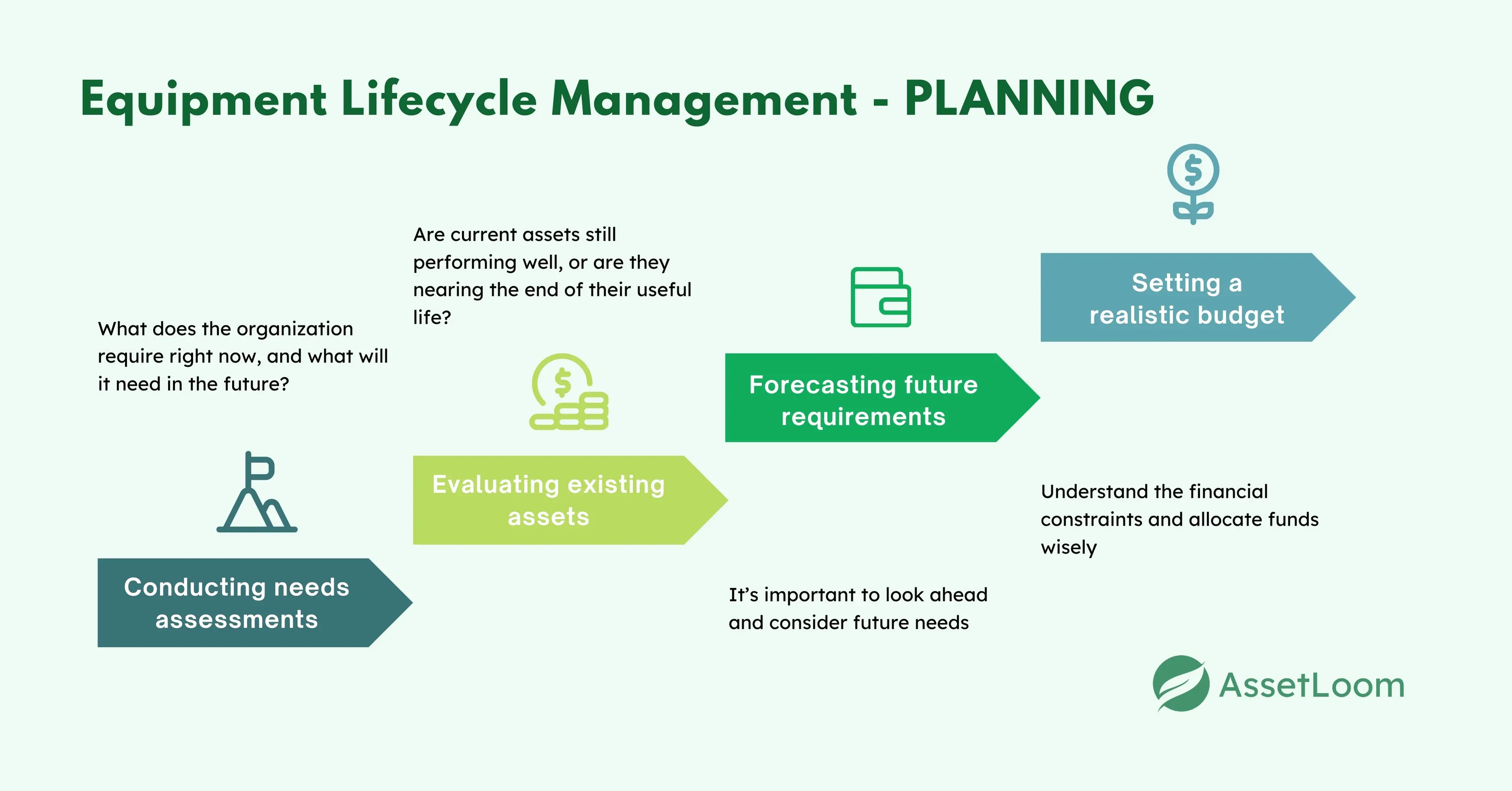

Planning

Planning is the foundation of effective equipment lifecycle management. It’s more than just a list of things to buy; it’s about understanding the organization’s needs, forecasting future demands, and ensuring that each piece of equipment fits into the broader business strategy. Taking the time to plan thoroughly can save considerable resources down the line and help avoid procurement mistakes.

What Happens in Planning?

This stage typically involves several steps to align equipment with business needs:

- Conducting needs assessments – What does the organization require right now, and what will it need in the future? For instance, a manufacturing plant might evaluate whether its current machinery can handle expected production volumes or if it needs an upgrade to meet future demands.

- Evaluating existing assets – Before purchasing new equipment, assess what’s already in place. Are current assets still performing well, or are they nearing the end of their useful life? This can help identify areas where upgrades or replacements are needed.

- Forecasting future requirements – It’s important to look ahead and consider future needs. For example, a growing business might need to plan for additional equipment to accommodate an expanding team or an increase in production capacity.

- Setting a realistic budget – Understand the financial constraints and allocate funds wisely. Planning for the total cost of ownership (not just the purchase price) ensures that all associated costs—like maintenance, training, and energy consumption—are considered.

“Planning is where most of the lifecycle costs are locked in—even before the asset is purchased.”

— U.S. General Services Administration

Why Planning Matters

Effective planning helps organizations avoid unnecessary costs and equipment mismatches. For example, a company might purchase overpowered equipment for tasks that don’t require it, leading to wasted budget and higher maintenance costs. Alternatively, underbuying or choosing underpowered equipment can hinder productivity and lead to premature replacements.

Planning also involves thinking about risks, such as equipment obsolescence, depreciation, and the impact of emerging technologies. For instance, a company in the tech industry might need to regularly assess whether its IT assets are at risk of becoming outdated due to fast-moving technological advancements.

Acquisition

The acquisition phase is crucial to ensure the equipment procured is not only the right fit for the organization’s needs but also cost-effective and sustainable throughout its lifecycle. This step involves much more than just placing an order it includes evaluating suppliers, negotiating favorable terms, and factoring in the total cost of ownership (TCO).

What Happens in Acquisition

- Evaluating suppliers – This involves researching potential vendors and comparing factors like reliability, product quality, after-sales support, and warranty terms. For example, a logistics company looking to replace its fleet of trucks might evaluate different vendors based on safety features, fuel efficiency, and maintenance records.

- Negotiating contracts – Once the right supplier is chosen, it’s time to negotiate the best terms. This includes agreeing on the price, delivery timeline, and warranty. The goal is to secure a deal that not only meets the organization’s needs but also stays within budget.

- Considering Total Cost of Ownership (TCO) – TCO isn’t just about the initial purchase price; it includes ongoing costs like maintenance, repairs, energy consumption, and eventual disposal or resale value. For example, purchasing an energy-efficient machine might come with a higher upfront cost but could save money in the long term through reduced operational expenses.

- IT Asset management Adding the new equipment to an IT asset management system for tracking is an important step. Systems like AssetLoom can help track the asset's lifecycle, from purchase to disposal, ensuring that the organization can manage its equipment effectively.

Why Acquisition Matters

Acquiring the right equipment goes beyond just buying what’s on sale or picking a vendor based on price alone. Focusing on the total cost of ownership and evaluating long-term implications helps avoid hidden costs like expensive repairs or the need for premature replacements.

For example, a company might be tempted to purchase a piece of equipment based on a low upfront cost, but if it has high maintenance or energy costs, the total lifecycle expenses can far exceed the initial savings. Proper evaluation helps to avoid these pitfalls.

Installation

Once equipment is acquired, the installation phase ensures that everything is set up correctly and ready for operation. Installation isn’t just about physically placing equipment in its designated space—it’s about integrating it into existing systems, ensuring safety standards are met, and confirming that the equipment functions as expected. A well-executed installation can prevent delays and costly mistakes down the line.

What Happens in Installation

- Site preparation – Before installing new equipment, it's important to prepare the site. This could involve setting up dedicated spaces, checking environmental conditions like power and ventilation, or upgrading infrastructure to meet the equipment's needs.

- Integration with existing systems – Whether it’s a complex CNC machine or a new IT server, proper integration with existing systems is crucial. This may require configuring software, connecting devices to networks, or ensuring compatibility with other systems in use.

- Testing for functionality, safety, and efficiency – Conducting initial tests is essential to verify that everything is working properly. Testing ensures that the equipment is operating safely and efficiently, which helps avoid downtime later. For example, when installing an IT server, you would check connectivity, data transfer speed, and security protocols to confirm everything is functioning as expected.

- Training staff – It's important to provide employees with proper training on how to use the new equipment. This ensures they understand its functions, how to maintain it, and how to troubleshoot basic issues. Training reduces the risk of misuse and helps improve overall efficiency.

Why Installation Matters

Installation might seem like a straightforward process, but if done improperly, it can result in operational inefficiencies, delays, or even equipment damage. For example, a misconfigured IT server might lead to security vulnerabilities or network performance issues. Improperly installed machinery might experience malfunctions or fail to meet safety standards, risking worker safety and legal consequences.

Proper installation ensures that the equipment operates at full capacity and integrates seamlessly into business processes, which can save time and money in the long term.

Operation

The operation phase is where equipment is actively used in daily business activities. This stage is vital for ensuring that the equipment meets the organization’s operational needs, such as improving efficiency, supporting productivity, or enhancing safety. Proper use of the equipment during this phase maximizes its value and extends its lifespan.

What Happens in Operation

- Active use in daily operations – The primary goal of the operation phase is to ensure that the equipment contributes effectively to day-to-day processes. For example, a conveyor belt system in a factory may be used to streamline production, reducing manual labor and speeding up output.

- Staff training and performance monitoring – Proper staff training is crucial to ensure that employees are familiar with how to use the equipment correctly and safely. Performance monitoring helps track whether the equipment is operating efficiently and whether there are areas for improvement. Regular assessments can help prevent issues before they affect operations.

- Gathering data on usage patterns – Tracking how often and how efficiently equipment is used provides valuable insights into its performance. This data helps optimize usage patterns, avoid underuse or overuse, and guide maintenance efforts to prevent costly downtime. Tools like asset management software can help collect and analyze this data, making it easier to make informed decisions about operations.

- Establishing Standard Operating Procedures (SOPs) – Creating clear, detailed SOPs ensures that equipment is used consistently and efficiently. SOPs help guide employees through the correct procedures for operating equipment, reducing the risk of errors or misuse. These guidelines can also streamline training for new staff.

Why Operation Matters

The operation phase is often the longest phase of the equipment lifecycle, as it directly impacts the equipment's value generation. Effective use during this phase can lead to improved productivity, reduced downtime, and extended equipment lifespan. However, improper use or neglect can lead to performance issues, higher maintenance costs, and even early equipment failure.

For example, an automated warehouse system can help a retailer improve inventory management and speed up order fulfillment. However, if the system isn't regularly monitored or optimized, it can lead to inefficiencies or breakdowns that affect the entire operation.

Maintenance

The maintenance phase is key to ensuring equipment runs smoothly and lasts as long as possible. Regular maintenance not only helps prevent unexpected breakdowns but also keeps costs down and ensures productivity stays high. Whether it's planned checks or fixing issues as they arise, keeping equipment in top shape is essential.

What Happens in Maintenance

- Preventive maintenance – This is all about taking action before problems arise. It includes things like regular inspections, lubricating moving parts, and replacing worn-out components. For example, lubricating a conveyor belt in a factory helps keep it running smoothly and avoids expensive breakdowns.

- Corrective maintenance – Sometimes things go wrong, and corrective maintenance is necessary. This could involve repairing broken parts or addressing unexpected issues that cause downtime. Quick fixes are important to minimize disruptions to operations.

- Creating a maintenance schedule – Scheduling maintenance tasks based on the manufacturer’s recommendations and real-world usage ensures that equipment is regularly checked. This might include setting reminders for inspections, cleaning, and part replacements to keep everything running efficiently.

- Predictive maintenance – This advanced approach uses technology like IoT sensors to predict when equipment might fail. By catching issues early, predictive maintenance allows you to fix small problems before they turn into big ones, helping avoid costly downtime.

- Tracking maintenance history – Keeping a detailed record of all maintenance activities is crucial. Using asset management software makes it easy to track repairs, inspections, and performance history. This data helps spot recurring issues and plan future maintenance needs.

Why Maintenance Matters

Well-maintained equipment is less likely to break down and can operate for a longer period, ultimately saving money and preventing disruptions. On the other hand, poor maintenance can lead to frequent breakdowns, higher repair costs, and downtime. Studies show that lack of maintenance can reduce productivity by as much as 20%, which can significantly affect the bottom line.

Disposal

Disposal is the final step in the equipment lifecycle. Once equipment is no longer useful, it needs to be decommissioned and disposed of properly. This step is important for sustainability, recovering costs, and complying with regulations. Whether selling old equipment, recycling parts, or following environmental guidelines, proper disposal helps reduce waste and ensures responsible asset management.

What Happens in Disposal

- Decommissioning – This step involves removing equipment from service and preparing it for disposal. It also includes securely wiping any sensitive data or information, especially for IT-related assets.

- Selling to secondary markets – Even though equipment is no longer needed, it may still hold value. Selling old items—like computers, servers, or vehicles—can help recover some of the original cost and prevent waste. For example, retired servers can be sold to other companies or resold for parts.

- Recycling – For equipment that can’t be resold, recycling is an eco-friendly alternative. Many parts, like metals and plastics, can be recycled, reducing landfill waste. Proper recycling also ensures compliance with environmental laws.

- Compliance with regulations – Disposal must meet all local and international environmental and safety standards. This ensures that hazardous materials, such as chemicals or batteries, are handled appropriately. Proper documentation of these processes is also necessary to avoid penalties and ensure compliance.

- Archiving records – It’s important to document everything about the disposal process. This includes keeping records of asset sales, recycling activities, and compliance with regulations. These records can be valuable for audits and future decision-making.

Why Disposal Matters

Proper disposal helps you stay compliant with regulations, recover value from old assets, and reduce environmental impact. Without a solid disposal plan, you could face legal issues, lose potential revenue, or harm the environment. Additionally, failing to properly decommission equipment—especially with sensitive data—could expose the company to security risks.

Conclusion

Managing the equipment lifecycle is an essential process that ensures your assets are used efficiently and effectively, from the initial planning stages to their eventual disposal. Each of the six core processes—Planning, Acquisition, Installation, Operation, Maintenance, and Disposal—plays a critical role in maximizing the value of your equipment, minimizing risks, and supporting long-term business goals.

By strategically planning for equipment needs, making informed acquisition choices, ensuring proper installation, actively managing operations, performing regular maintenance, and disposing of assets responsibly, businesses can optimize asset performance, reduce costs, and support sustainability efforts.

RELATED BLOGS

Related Blogs

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox