Asset Life Cycle Stages Explained: Applications Across Industries

Asset life cycle stages streamline IT asset management, saving costs and ensuring compliance. Learn planning, acquisition, operation, maintenance, and disposal with practical tips.

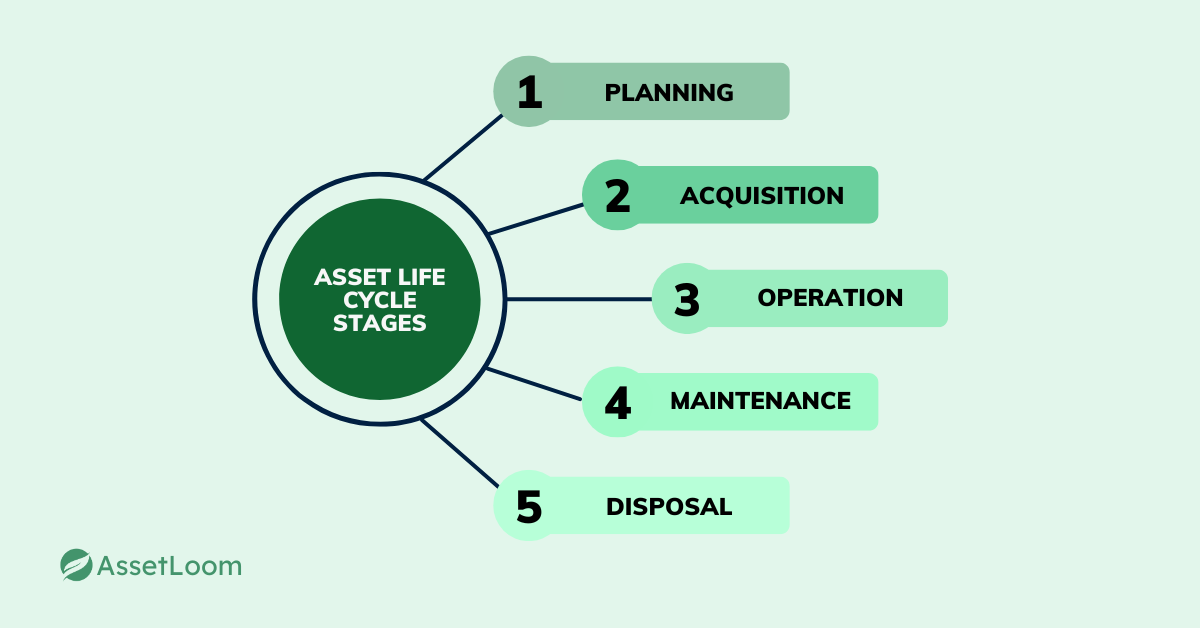

The asset life cycle stages offer a clear framework for managing IT hardware, medical equipment, or industrial machinery effectively. These five steps, planning, acquisition, operation, maintenance, and disposal, help IT professionals and asset managers keep assets organized, save money, and stay compliant. AssetLoom simplifies this process, making it easier to track and manage your assets.

In this blog, we’ll explain each stage with practical tips and examples from IT and other industries, like healthcare and manufacturing. Our goal is to help you streamline your processes and avoid common mistakes. Let’s explore how the asset life cycle stages can make your assets work smarter for you.

What Are the Asset Life Cycle Stages?

The asset life cycle stages form the foundation of effective IT asset management (ITAM). These five steps, planning, acquisition, operation, maintenance, and disposal, guide how you manage assets from start to finish. Picture your assets like a car: you plan what you need, buy it, use it, maintain it, and eventually replace it. This cycle applies to IT equipment, like laptops and servers, as well as manufacturing machinery or hospital devices.

Why does this matter? Following these stages ensures cost savings, compliance, and data accuracy. For example, poor planning can lead to overspending, while careless disposal risks data breaches. In industries like healthcare or logistics, where assets are critical, mastering the cycle prevents downtime and penalties. By understanding each stage in IT Asset lifecycle Management, you can keep your assets running smoothly, whether you’re in IT or managing a factory floor.

Stage 1: Planning, Setting the Foundation

Planning is the first of the asset life cycle stages, laying the groundwork for success. This stage involves assessing needs, setting budgets, and forecasting future requirements. For example, a hospital might plan to upgrade MRI machines based on patient demand, while an IT team forecasts laptop replacements for remote workers. Here are some practical tips to nail the planning stage:

- Involve stakeholders: Get input from IT, finance, and operations to align with business goals.

- Use historical data: Review past asset performance to predict needs accurately.

- Forecast demand: Anticipate growth, like a retail chain planning for new stores.

- Leverage ITAM tools: Software like AssetLoom centralizes data for smarter decisions.

A common challenge is underestimating costs, like forgetting maintenance budgets. The solution is to build a buffer and use ITAM software for data accuracy. Planning without data is like cooking without a recipe, you might end up with a mess. Take time to get this stage right, and the rest of the cycle will run smoothly.

Laptop journey: A company plans to buy laptops for a new team, determining how many, what specs, and the budget based on workload needs. Without a solid plan, you risk overspending or buying too little.

Stage 2: Acquisition, Bringing Assets Onboard

Acquisition is where you put plans into action in the asset life cycle stages. This stage covers purchasing or leasing assets, from IT hardware to industrial equipment. For example, a retail chain might buy point-of-sale systems for new locations, while an IT department leases cloud servers. Laptop journey: The company buys the planned laptops, comparing vendors for the best price and ensuring they meet security standards. Done right, acquisition ensures you get the right assets at the best price. Done wrong, it leads to budget overruns.

Here’s how to ace acquisition:

- Compare vendors: Shop around to find the best quality and price.

- Negotiate contracts: Secure favorable terms, like extended warranties.

- Check compliance: Ensure assets meet industry standards, like HIPAA for medical devices.

- Document everything: Track purchase details for audits and future reference.

A big challenge is rushed purchases, which can cause overspending or poor fit. A manufacturing firm, for instance, might buy incompatible machinery without research. The fix is to evaluate options carefully and use ITAM tools to track vendor data. Buying assets without research is like adopting a pet without checking if it bites, do your homework to avoid surprises.

Laptop journey: The company buys the planned laptops, comparing vendors for the best price and ensuring they meet security standards. Done right, acquisition ensures you get the right assets at the best price. Done wrong, it leads to budget overruns.

Stage 3: Operation, Keeping Assets in Play

The operation stage is where your assets deliver value in the asset life cycle stages. This is when you deploy and use assets, like assigning laptops to employees or running machinery in a factory. For example, a logistics company tracks delivery trucks to optimize routes, while an IT team monitors server performance. Here are some tips for the operation stage:

- Track usage: Use ITAM software to monitor who’s using what and how.

- Integrate with CMDB: Centralize data for streamlined processes and visibility.

- Conduct regular audits: Ensure assets are being used as intended.

- Train users: Teach employees to use equipment properly to avoid misuse.

A common pitfall is underutilization, like laptops sitting unused in storage. Real-time tracking with tools like AssetLoom can spot these issues early. If your IT systems were a family, CMDB integration would be the peacemaker, keeping everything in sync. Stay proactive, and your assets will deliver maximum value without drama.

Laptop journey: The laptops are assigned to employees, tracked via software to ensure proper use. The goal is to maximize value while keeping everything running smoothly.

Stage 4: Maintenance, Extending Asset Life

Maintenance is the unsung hero of the asset life cycle stages, keeping assets in top shape. This stage includes tasks like software updates for IT equipment or calibration for medical devices. For example, a data center schedules server maintenance to prevent crashes, while a construction firm services cranes to avoid breakdowns. Try these maintenance tips:

- Schedule regular checkups: Plan updates or inspections to catch issues early.

- Use predictive maintenance: Leverage data to predict failures, like in manufacturing.

- Document repairs: Keep records for compliance and future planning.

- Train technicians: Ensure staff know how to maintain specialized equipment.

Unplanned downtime is a major challenge, especially in industries like healthcare where delays can impact patients. Predictive tools and ITAM software can help. Neglecting maintenance is like skipping oil changes, your assets won’t thank you. By staying proactive, you can extend asset life and keep operations running smoothly.

Laptop journey: The laptops receive regular software updates and hardware checks to keep them running smoothly. Regular upkeep extends asset life and prevents costly downtime.

Stage 5: Disposal, Saying Goodbye Responsibly

Disposal is the final step in the asset life cycle stages, focusing on retiring assets responsibly. This means recycling, reselling, or securely wiping data from old equipment. For example, an IT team might erase hard drives before recycling, while a restaurant replaces outdated kitchen appliances. Here’s how to handle disposal:

- Wipe data securely: Use certified tools to prevent data breaches.

- Choose reputable vendors: Partner with certified e-waste recyclers.

- Explore resale options: Sell functional assets to recover value.

- Document disposals: Track every step for audits and compliance.

A big challenge is data security, especially in IT, where breaches can be costly. Certified disposal processes mitigate this risk. Disposal isn’t just tossing assets in a dumpster, it’s more like a respectful farewell. With tools like AssetLoom, you can track disposals and ensure compliance, making this stage as smooth as the rest.

Laptop journey: The laptops, now outdated, are wiped of data and sent to a certified e-waste recycler. Done right, disposal ensures compliance and supports sustainability.

Applying the Asset Life Cycle Stages Across Industries

The asset life cycle stages aren’t just for IT, they apply to any industry with valuable assets, like healthcare, manufacturing, or retail. Each sector uses the cycle to manage equipment, reduce costs, and meet regulations. Here’s how the stages work beyond IT, with real-world examples:

-

Healthcare (MRI machine):

- Planning: A hospital assesses patient demand and budgets for a new MRI machine.

- Acquisition: They compare vendors and purchase a machine that meets FDA standards.

- Operation: The machine is used for patient scans, tracked for scheduling efficiency.

- Maintenance: Regular calibration and software updates prevent downtime.

- Disposal: The old machine is decommissioned, with parts recycled per regulations.

-

Manufacturing (CNC machine):

- Planning: A factory forecasts production needs and plans for a new CNC machine.

- Acquisition: They lease the machine, ensuring it fits production line specs.

- Operation: The machine runs daily, tracked for output and efficiency.

- Maintenance: Scheduled servicing and predictive maintenance avoid breakdowns.

- Disposal: The machine is resold or scrapped, with hazardous materials handled safely.

-

Retail (POS system):

- Planning: A chain plans for new point-of-sale systems to support expansion.

- Acquisition: They buy systems after negotiating bulk discounts.

- Operation: Systems are deployed in stores, monitored for transaction speed.

- Maintenance: Regular software updates ensure security and performance.

- Disposal: Old systems are wiped of data and recycled responsibly.

These examples show that Mastering the asset life cycle stages is about more than just following steps, it’s about saving money, staying compliant, and boosting efficiency. Each stage, from planning to disposal, builds on the last to create a seamless process. Trends like sustainability in disposal or AI-driven maintenance show how critical this cycle is across industries. For example, healthcare facilities use it to comply with regulations, while manufacturers reduce downtime. Poor management, on the other hand, leads to overspending, audits, or data breaches.

AssetLoom simplifies this process by centralizing data and automating tasks like tracking and reporting. Whether you’re managing IT hardware or factory equipment, a strong asset life cycle strategy delivers cost savings and peace of mind. Ready to see how your process stacks up? Use the checklist below to spot gaps and take control of your assets.

Self Assessment Checklist: How’s Your Asset Life Cycle Process?

Want to know how your asset management measures up? Use this checklist to evaluate your asset life cycle stages. Answer these questions to identify strengths and gaps. Because who doesn’t love an audit that doesn’t feel like a root canal?

- Planning: Do you have a clear plan for asset needs based on data and stakeholder input?

- Acquisition: Are you comparing vendors and documenting purchases for compliance?

- Operation: Do you track asset usage in real-time to avoid underutilization?

- Maintenance: Is there a schedule for regular upkeep to prevent downtime?

- Disposal: Are you securely wiping data and using certified recyclers?

- Overall: Does your ITAM software, like AssetLoom, centralize data for all stages?

If you answered “no” to any, it’s time to tighten up. AssetLoom can help streamline your process and fill those gaps. Share your results with your team and start making improvements today.

Conclusion

The asset life cycle stages, planning, acquisition, operation, maintenance, and disposal, are your roadmap to smarter asset management. By mastering each stage, you can cut costs, stay compliant, and keep your operations running smoothly. From IT departments to hospitals and factories, these steps help you avoid chaos and make your assets heroes, not headaches. Use the checklist above to assess your process, and explore tools like AssetLoom to simplify every stage. Ready to take control? Start today, and watch your assets work smarter for you.

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox