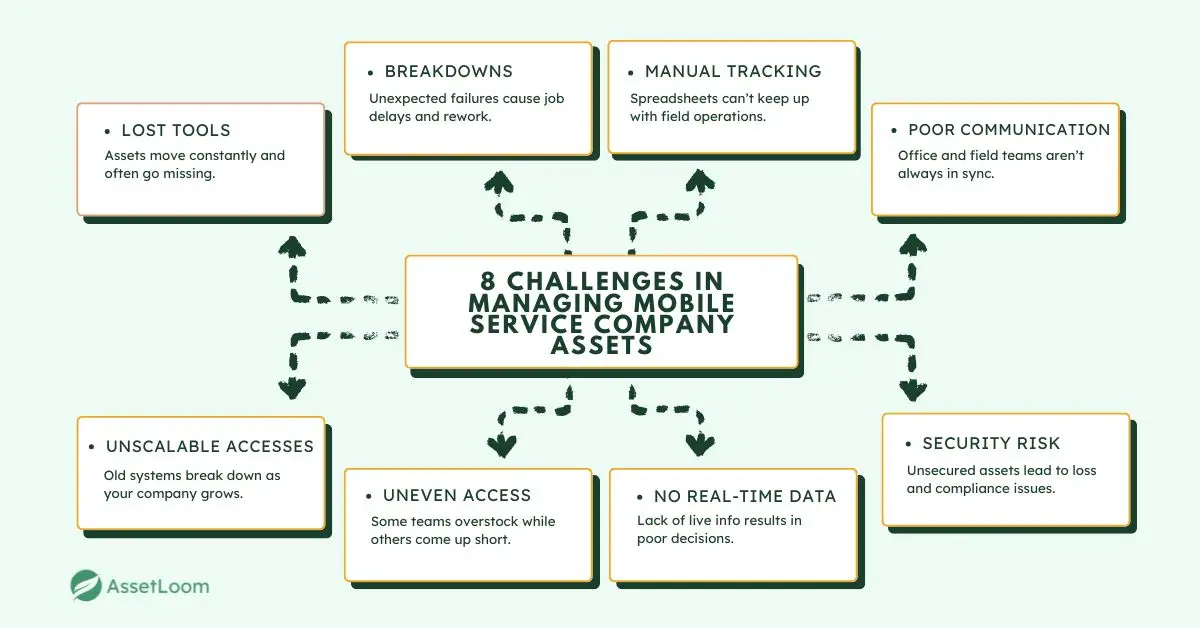

8 Common Challenges in Managing Mobile Service Company Assets

Learn the top 8 challenges in managing Mobile Service Company Assets and how they affect your business.

Your technician’s late. The tool they need? Missing. The backup? Broken. And your customer? Already dialing a competitor.

Welcome to the everyday chaos of managing Mobile Service Company Assets—where equipment is always in motion, accountability is foggy, and every small mistake turns into a big, expensive problem.

If this feels familiar, you're not alone. The truth is, most mobile service teams are battling asset issues they can’t even see coming.

Here are the 8 biggest challenges holding your operations back, starting with the one no one wants to admit.

Why Managing Mobile Service Company Assets Is So Tricky

Asset management in a mobile service company isn’t just hard—it’s uniquely complicated. Unlike a fixed office environment, your tools, equipment, and devices are constantly moving between field technicians, service vehicles, job sites, and storage hubs.

One minute, a tool is signed out; the next, it's unaccounted for. Devices get shared across teams. Equipment gets left behind at job sites or buried in the back of a van. Without a reliable system in place, it’s almost impossible to know what you have, where it is, and what condition it’s in.

Even worse? Most teams are still relying on spreadsheets, whiteboards, or verbal updates. That might work when you’re managing five techs—but not fifty. And definitely not when every delay costs time, customer satisfaction, and revenue.

Managing Mobile Service Company Assets means juggling speed, scale, and accountability—often without the tools to do it right. That’s why more companies are turning to structured systems like IT Asset Management (ITAM) to bring control and visibility into the chaos.

Challenge #1: Losing Track of Mobile Service Company Assets

In a mobile service company, tools and equipment are always moving—from technicians, to vans, to job sites. Without a solid way to track them, things get lost or misplaced. And that’s more than just annoying.

Imagine a technician arrives at a client’s site only to find the tool they need is missing. Instead of fixing the problem, they waste hours looking for it or waiting for a replacement. That delay messes up your schedule, frustrates the customer, and wastes your team’s time.

But it doesn’t stop there. Lost assets mean repeated purchases for replacements, overstocking ‘just in case,’ and extra admin hours spent tracking down missing gear. This cycle drains budgets and wears down your team’s morale.

Losing track of assets isn’t a small problem—it costs you money, slows down work, and hurts your reputation. In mobile service, every minute lost is a missed opportunity.

Challenge #2: Equipment Fails When You Least Expect It

Tools breaking down on the job can bring a whole day to a halt. Mobile service technicians rely on specialized equipment, and when one device suddenly fails, the whole repair or service can get delayed or canceled.

For example, a technician might be halfway through a critical job when their diagnostic tool dies or malfunctions. Without a backup or a quick replacement, they have no choice but to pause work and scramble for solutions.

These breakdowns don’t just slow you down—they throw off your entire schedule, frustrate customers waiting for timely service, and increase operational costs with last-minute rentals or emergency purchases.

Unpredictable equipment failure means lost time, lost revenue, and a hit to your team’s reliability and customer trust.

Challenge #3: Outdated or Manual Inventory Tracking

Many mobile service companies still use spreadsheets, paper logs, or word-of-mouth to keep tabs on their tools and equipment. These manual methods are slow, prone to mistakes, and can’t keep up as your team and asset pool grow.

Imagine the chaos when multiple people try updating the same spreadsheet or when handwritten logs get lost or forgotten. This leads to confusion about what’s available, what’s broken, and what needs ordering, making your job harder and more stressful.

Manual tracking also means updates happen too late or not at all, causing dispatchers and managers to make decisions based on incomplete or inaccurate data. This leads to wasted trips, idle technicians, and missed deadlines.

Without an automated, real-time system, managing assets feels like fighting a losing battle—one that drains time, money, and confidence.

Challenge #4: Poor Communication Between Field and Office

Clear communication between field technicians and office staff is essential for smooth asset management. But when teams aren’t connected, it’s easy for vital information to fall through the cracks.

For example, dispatchers might send a technician to a job with tools that are still out on another site or waiting for repair. Or technicians may not report broken or missing equipment promptly, leaving the office unaware of issues until it’s too late.

This miscommunication wastes time, creates scheduling conflicts, and frustrates both workers and customers. It can even lead to costly repeat visits or rushed fixes that hurt your company’s reputation.

Without real-time updates and a shared system, bridging the communication gap is nearly impossible, and it costs your business dearly.

Challenge #5: Security and Compliance Risks

Mobile assets leave the safety of your office every day, traveling in vans, on job sites, and sometimes in the hands of multiple technicians. Without strong security measures, equipment can easily be lost, stolen, or misused.

For example, a valuable diagnostic device might go missing after being left unsecured on-site, or a tool might be borrowed and never returned. This isn’t just frustrating—it can cost thousands in replacement and downtime.

On top of that, many industries require strict compliance with asset tracking and data protection rules. Failing to meet these standards can lead to hefty fines and damage your company’s reputation.

Protecting your assets isn’t just about cutting losses—it’s about keeping your business safe, compliant, and trusted by customers.

Challenge #6: Lack of Real-Time Data and Visibility

Without real-time insight into where your mobile assets are and how they’re being used, you’re always a step behind. Most teams only find out something’s missing or broken after it’s too late to prevent delays.

Imagine dispatchers sending technicians out with the wrong equipment because their system hasn’t been updated. Or managers trying to plan jobs without knowing which tools are currently in use or out for repair. This lack of visibility creates constant guesswork.

When you don’t have accurate, up-to-the-minute data, scheduling becomes a headache, costs rise, and customer satisfaction takes a hit. Real-time tracking isn’t just a nice-to-have—it’s critical for smooth, efficient operations.

Challenge #7: Inconsistent Asset Usage and Allocation

Without clear policies and systems to control how assets are used and shared, chaos quickly sets in. Some technicians might hold onto tools longer than needed, while others scramble to borrow or replace gear.

For example, one tech’s van might be packed with rarely used equipment, while another’s is missing essential tools because no one knows where they went. This imbalance causes delays, unnecessary spending, and frustration across the team.

Inconsistent asset allocation wastes money and productivity. Setting clear rules and tracking usage helps ensure every piece of equipment is working where it’s needed most.

Challenge #8: Difficulty Scaling Asset Management Processes

What works for a small mobile service team often breaks down as you grow. Managing more technicians, job sites, and assets manually or with outdated systems quickly becomes overwhelming.

For example, a company might start with a simple spreadsheet and verbal check-ins, but when the team doubles or triples, mistakes multiply. Equipment goes missing, updates get missed, and accountability fades.

Without scalable asset management tools and processes, growth turns into chaos. To keep up with increasing demand and complexity, you need systems designed to grow with you, giving you control, visibility, and confidence at every step.

Conclusion

Running a mobile service company is already demanding. With teams on the move and jobs constantly shifting, it’s easy for tools to go missing and communication to break down. And when that happens, your team loses time, customers lose patience, and costs quietly pile up.

Solving these issues takes more than just working harder. It starts with better visibility—the kind that smart IT asset tracking can bring to your operations behind the scenes.

Because staying in control shouldn’t feel impossible.

Related Blogs

ITAM in General

Fixing Inventory Sync Issues Between ITAM and ITSM Tools

ITAM in General

The Hidden Costs of a Stolen Work Laptop & How to Prevent Them

Subscribe for Expert Tips and Updates

Receive the latest news from AssetLoom. right in your inbox